This is where you find all our press releases and news articles.

Grass fuel pellets are a type of biomass fuel made from dried and compressed grass. They are cylindrical in shape, typically 6-10 mm in diameter and 10-30 mm in length. Grass pellets are a renewable energy source, offering an eco-friendly alternative to fossil fuels like coal and natural gas. They are produced through a process called pelletization, which involves grinding, drying, and compressing grass into dense, energy-rich pellets.

Grass fuel pellets are part of the broader category of biomass pellets, which also include wood pellets, straw pellets, and other organic materials. However, grass pellets have unique properties that make them suitable for specific applications, such as heating, power generation, and even as a feedstock for biogas production.

Not all grasses are equally suitable for pellet production. The ideal grasses for fuel pellets have the following characteristics:

They are fast-growing and require minimal inputs.

They have a high calorific value, making them efficient for energy production.

They are widely available in many regions, reducing transportation costs.

The production of grass fuel pellets involves several steps to ensure high-quality, energy-dense pellets. Here is the complete processing flow:

Harvesting: Grass is cut and collected using agricultural machinery.

Chopping: The grass is chopped into smaller pieces to facilitate drying and grinding.

Grass typically has a high moisture content (50-70%), which must be reduced to 10-15% for pelletization.

Drying Equipment: Rotary dryers or belt dryers are used to remove excess moisture.

The dried grass is ground into a fine powder using a hammer mill or grinding machine.

Particle Size: The ideal size is 3-5 mm for efficient pelletization.

The ground grass is fed into a grass pellet machine, where it is compressed under high pressure and temperature.

Binding: The natural lignin in the grass acts as a binder, holding the pellets together.

The hot pellets are cooled to room temperature using a pellet cooler.

Purpose: Cooling hardens the pellets and reduces moisture.

The pellets are screened to remove fines and dust, ensuring uniform size and quality.

The finished pellets are packaged in bags or stored in bulk for distribution.

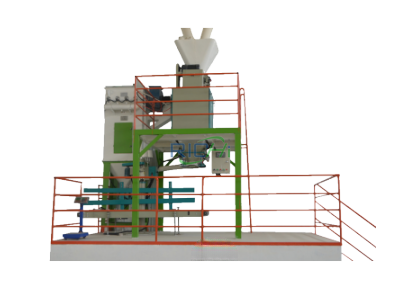

To set up a grass fuel pellet production line, the following equipment is essential:

The cost of building a grass fuel pellet production line depends on the scale and complexity of the operation. Here's a breakdown:

Grass fuel pellets are a promising renewable energy source with numerous applications. By understanding the processing technology, equipment requirements, and investment costs, businesses can capitalize on this growing market. With the right approach, grass pellet production can be a profitable and sustainable venture, contributing to a greener future. If you want to start a grass fuel pellet processing project or a grass feed pellet processing project, feel free to contact RICHI MACHINERY to obtain information on process design and equipment solutions, civil engineering solutions and production line layout. Now you can go to our case page to find more information: https://www.pellet-richi.com/project/!

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.