This is where you find all our press releases and news articles.

At present, many countries in the world, especially developed countries, have formulated and implemented organic fertilizer resource management policies. Many areas in the United States are actively conducting research on protective technologies in agricultural production, such as harmless organic fertilizers, soil testing and fertilization, and other protective farming technologies.

The United States also attaches great importance to the management of agricultural inputs and cultivates awareness of agricultural product safety. Many countries have formulated strict animal manure management laws to promote the harmless treatment and resource utilization of organic waste such as livestock and poultry manure.

The use of organic fertilizers in Western countries such as the United States, Japan, and the United Kingdom has accounted for about 50% of the total fertilizer use, which is much higher than the level of use in my country's domestic market. In 2022, the global organic fertilizer market size will grow to US$164.544 billion, and it is expected that the global organic fertilizer market size will reach US$206.3 billion in 2028.

The main feature of the development of the global organic fertilizer industry is that the consumption area is obvious, mainly concentrated in Europe, America, Asia and other regions with relatively developed economies and developed planting industries. Among them, the use of organic fertilizers in Western Europe accounts for the highest proportion of about 31.8%, North America accounts for about 29.9%, Asia-Pacific accounts for about 21.7%, and other regions account for about 16.6%.

The development of global organic agriculture has driven the rapid development of the entire organic fertilizer market, and the organic fertilizer market will show a long-term growth trend.

At present, the IFOAM organization has developed into the world's most extensive, largest and most authoritative international organic agriculture organization with more than 570 collective members from 115 countries. This also indicates that the overall development trend of the international market for organic fertilizers is increasing year by year.

However, each different market has its own unique situation and characteristics.

In the United States and Japan, where the fertilizer industry is developed, a large amount of organic fertilizer and bio-organic fertilizer are used in agricultural production. This cannot but be said to be a new trend in world agriculture.

With the maturity of the markets in developed organic fertilizer countries such as Europe, the United States, and Japan, the global organic fertilizer market will gradually tilt towards agricultural developing countries such as China. With the development of my country's organic fertilizer market, it is expected that by 2026, the global organic fertilizer industry will have the highest consumption in the Asia-Pacific region.

In developed countries in Europe and America, the application of agricultural organic fertilizer is generally above 50%; in Japan, the input of organic fertilizer accounts for more than 76%; in China, 26% of cultivated land has less than 1% organic matter, and 44.8% has less than 1% organic carbon.

According to data from the Agricultural Technology Extension Center of the Ministry of Agriculture, the proportion of organic fertilizer in the total fertilizer input in my country has dropped from 99.9% in 1949 to less than 20% in 2017, and it continues to decline.

In the context of chemical fertilizers becoming the main fertilizer, the efficient use of organic waste resources, the role of organic fertilizers in modern agricultural production, and the promotion of the sustainable development of modern agriculture have become an important issue of increasing concern to countries around the world.

Accelerating and encouraging the input of organic fertilizers and reducing the application of chemical fertilizers have become national policies generally implemented by countries. The main characteristics of the organic fertilizer industry in developed countries include:

The production technology of organic fertilizers in developed countries is gradually developing towards intensive and high-value directions, and organic compound fertilizers have become the main direction of organic fertilizer development.

In particular, we should strengthen the screening of functional bacteria that can quickly degrade lignin and cellulose from livestock and poultry manure and straw organic waste, the development of high-temperature composting agents, composting catalysts that accelerate decomposition, rapid decomposition composting technology and related equipment and machinery, as well as the development of compound functional organic fertilizers and bio-organic fertilizers for special purposes such as rapid restoration of degraded soils, elimination of continuous cropping obstacles, and improvement of agricultural product quality.

In terms of management, we have formulated relatively complete standardized production and management technologies for organic fertilizers, including standardized production technical specifications, rapid detection technologies for organic materials and product quality, product quality standards and market management specifications.

In recent years, organic fertilizer production in developed countries has developed rapidly, and has reached the level of scale and industrialization in composting fermentation processes, technologies and equipment. For example, the US BIOTEC2120 high-temperature composting system consists of 10 large rotating bioreactors.

Through microbial fermentation, it can process 1,300 tons of garbage within 72 hours and turn it into high-quality organic fertilizer. This method has a special effect on high-humidity materials. The method was granted a US patent in June 1993 and was recognized by the United Nations International Environmental Protection Organization. The US BEARD-ABT dynamic high-temperature composting is carried out in a closed 8×8×8 meter fermentation tower, and has an assembly function.

It also has five invention patents, especially the air spray guns distributed in the fermentation tower, which can automatically perform ventilation and induced draft conversion according to the needs of the composting process, so as to achieve the overall best biological reaction process. In Japan, livestock and poultry manure composting has been industrialized. The horizontal rotary drum and vertical multi-layer rapid composting devices they developed have a fermentation time of about one to two weeks, with the characteristics of small footprint, fast fermentation, and excellent texture.

The organic fermentation device developed by Russia produces 100 tons of organic fertilizer per day, and the final finished fertilizer contains about 45 kilograms of nitrogen, phosphorus and potassium per ton. However, foreign equipment is generally expensive, with high operating and maintenance costs, and it is difficult to directly promote and apply it in China.

Detecting the quality of organic fertilizer products is the guarantee of safe agricultural use of organic fertilizers. Researching and developing rapid monitoring technologies and methods for organic fertilizer quality that meet the needs of modern factory composting has important practical significance for guiding the production of organic fertilizers and organic-inorganic compound fertilizers.

With the development of analytical technology and microbiological technology, advanced and fast organic fertilizer quality assessment methods continue to emerge abroad. According to different analytical methods, some indicators and standards with their own characteristics have been established, including physical indicators, chemical indicators, biological indicators, and spectral analysis.

Among them, physical indicators are easy to monitor and are used to qualitatively describe the state of the composting process; the application of nuclear magnetic resonance NMR, infrared spectroscopy FT-IR, and chromatography technology reveals the changes in the microscopic material structure of compost, which helps to evaluate the rationality of chemical indicators; biological indicators can comprehensively reflect the stability and practicality of compost.

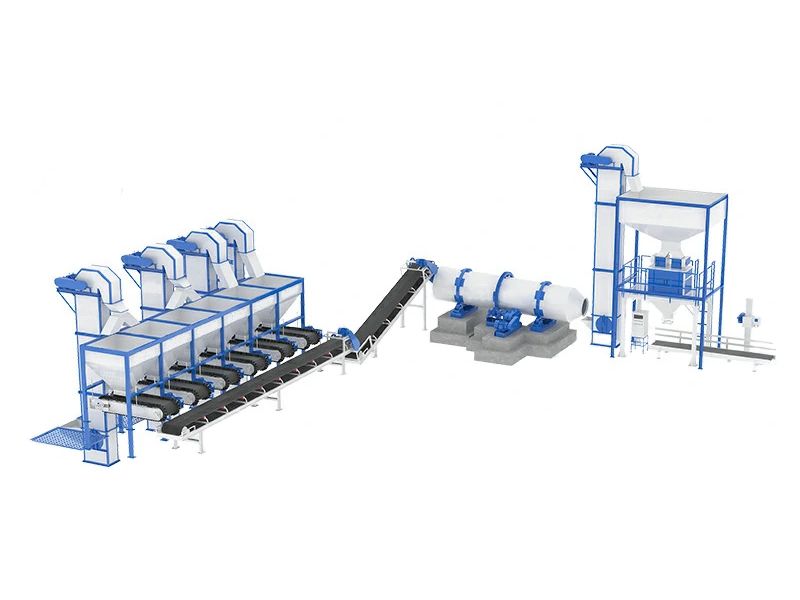

As a professional organic fertilizer equipment manufacturer, RICHI MACHINERY provides a full set of equipment including organic fertilizer pellet machines, organic fertilizer dryers, organic fertilizer crushers, etc., and provides the construction of organic fertilizer production line projects, including civil engineering, design, installation, commissioning, training, after-sales and other services. If you want to carry out an organic fertilizer production project, feel free to contact us for professional solutions.

Below are some of our organic fertilizer projects. If you are interested in any project, you can click to enter for details!

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.