This is where you find all our press releases and news articles.

How to Make Alfalfa Pellets with Alfalfa Granulator Machine? How to make alfalfa grass pellet for feed? How to make alfalfa grass pellet by alfalfa pellet machine Alfalfa pellet machine is the main mechanical method and equipment for the grass industry to process hay forage, connecting the peak season of grass with the green and yellow grass seasons. It mainly includes fresh alfalfa grass crushing, drying, mixing, pelleting, cooling, screening and packaging.

Alfalfa, often referred to as the "Queen of Forages," is a highly nutritious forage crop that is widely used in livestock feed. Its high protein content, vitamins, and minerals make it an ideal feed for cattle, horses, sheep, and other ruminants. However, fresh alfalfa has a short shelf life and can be difficult to store and transport. This is where alfalfa pellets come into play.

By converting alfalfa into pellets, farmers can extend its shelf life, reduce storage space, and make it easier to handle and transport. In this article, we will explore how to make alfalfa pellets using an alfalfa granulator machine, the technology behind the machine, its applications, pricing, and the complete set of equipment needed for the process.

The process of making alfalfa pellets involves several steps, each of which is crucial to ensuring the quality of the final product. Below is a detailed breakdown of the process:

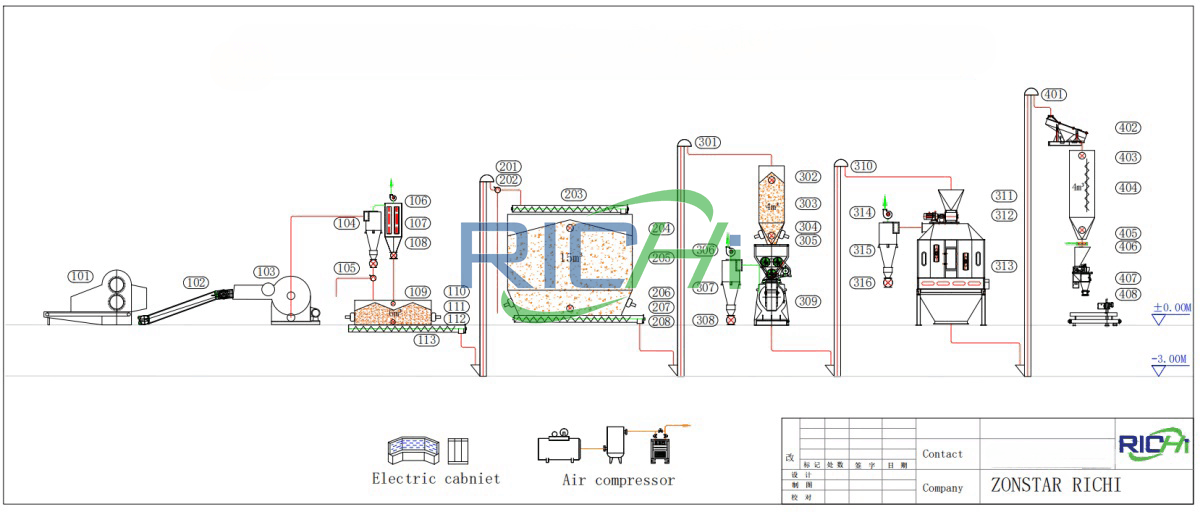

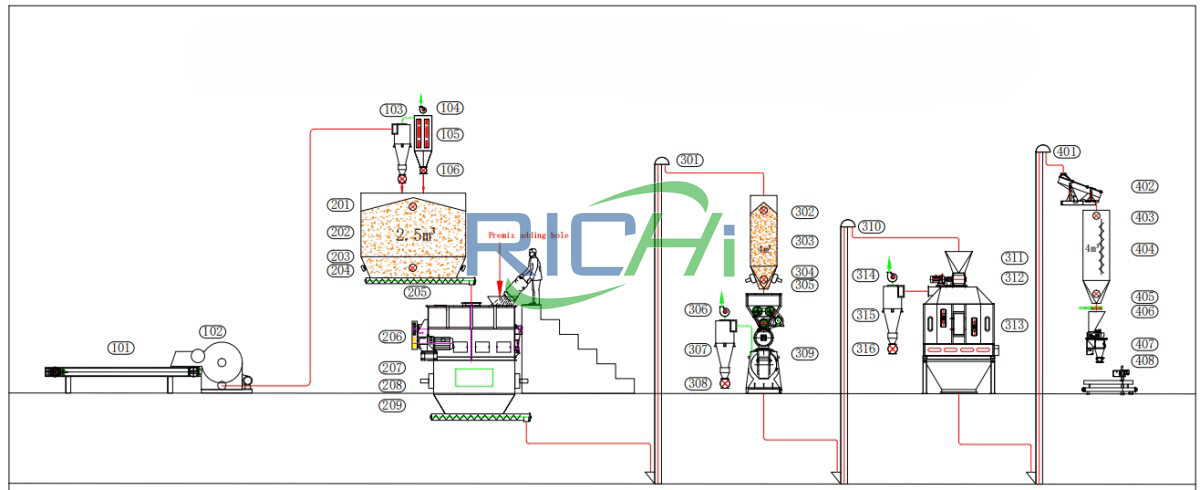

All of the above sections can be flexibly adjusted according to your raw material conditions and process requirements. According to the special process requirements of some customers, sometimes many work sections will be added, such as storage system, mixing system, flushing system, dust removal system, etc.

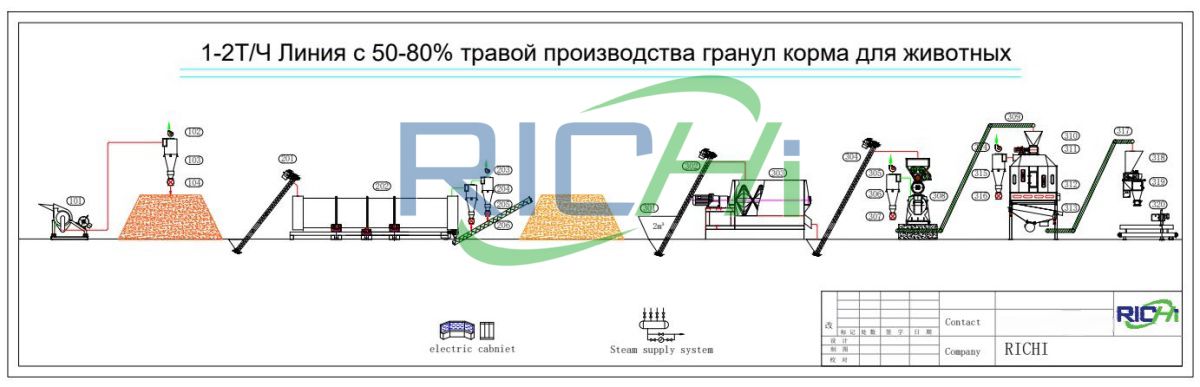

Your raw material may be pure alfalfa, or it may be added with a lot of grains and cereals, or it may be added with other grasses or biomass, such as straw, elephant grass, sunflower husks, etc. Your raw material may be alfalfa haystack, fresh grass, grass powder, or very long grass.

No matter what the raw material type is, what your formula is, and what the material state is, our engineers will determine the final process plan based on your raw material and product requirements, and provide you with corresponding equipment quotation, installation and training plans.

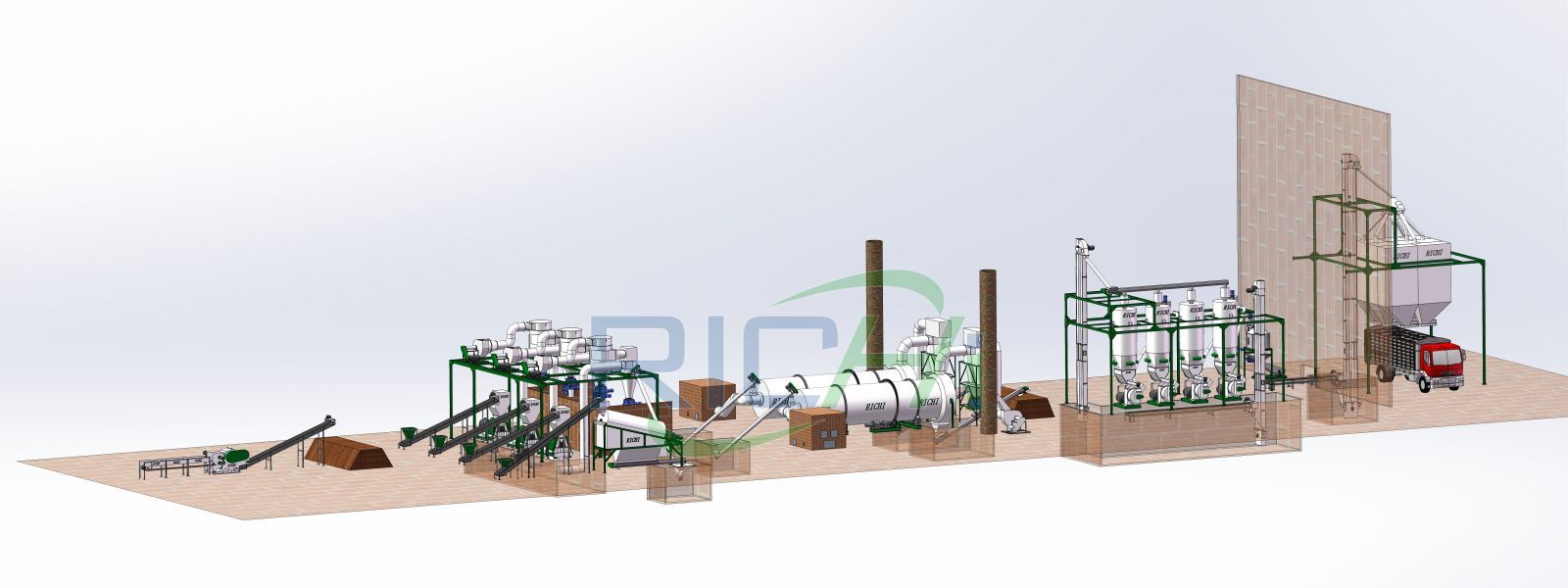

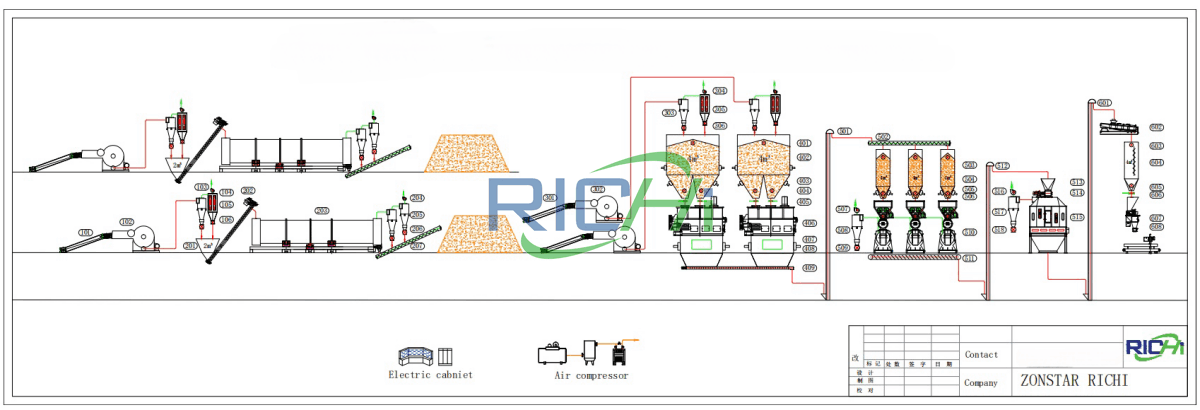

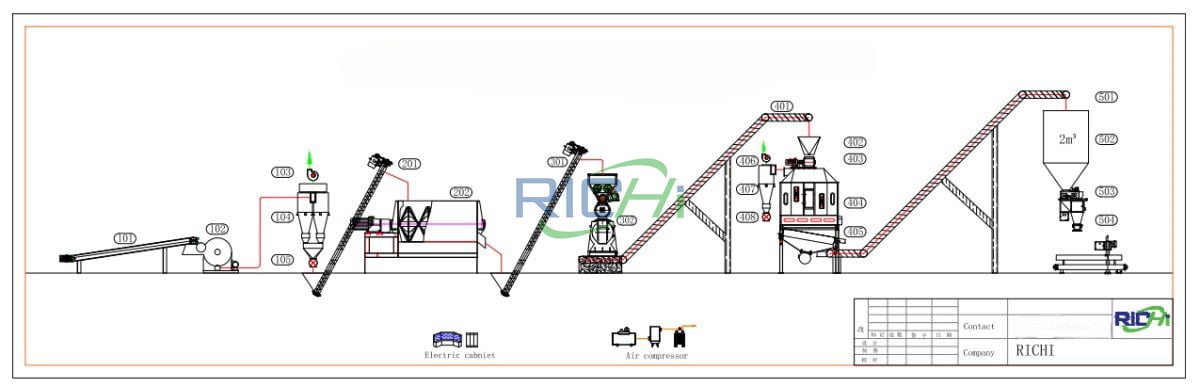

Below, we will list several typical alfalfa pelletizing system design solutions for you. These processes are all customized according to customer needs and are applied to our projects in the Russia, USA, Australia, Argentina, and Brazil.

The alfalfa granulator machine is the heart of the pellet production process. It is designed to efficiently compress and extrude alfalfa into high-quality pellets. Below are some of the key technical features of a modern alfalfa granulator machine:

The alfalfa grass pellet machine is equipped with a high-compression die that ensures the alfalfa is tightly compressed, resulting in dense and durable pellets. This is important for maintaining the nutritional value of the alfalfa and preventing the pellets from breaking apart during handling and transport.

The die and roller gaps can be adjusted to control the size and density of the pellets. This flexibility allows producers to customize the pellets according to the specific needs of their livestock or market demands.

Alfalfa granulator machines are built to withstand the rigors of continuous operation. They are typically made from high-quality steel and feature robust components that are resistant to wear and tear.

The machine is powered by a high-efficiency motor that ensures smooth and consistent operation. The motor is designed to handle the high torque required for pelletizing, ensuring that the machine can process large volumes of alfalfa without overheating or breaking down.

Modern alfalfa granulator machines are designed for easy maintenance. Key components such as the die and rollers can be easily accessed and replaced, minimizing downtime and ensuring continuous production.

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch feeder power (kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced feeder power (kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring die inner diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished pellet diameter (mm) | 4~12 | |||||

| Output(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The price of an alfalfa granulating machine can vary widely depending on its capacity, features, and brand.

| Model | Capacity | Grass pellet mill price |

| CZLH250 | 0.3-2T/H | 7,500- 8,000 $ |

| CZLH320 | 0.5-4T/H | 19,000-22,000 $ |

| CZLH350 | 1-6T/H | 24000-26,000 $ |

| CZLH420 | 2-10T/H | 30,000-32,000 $ |

| CZLH520 | 3-12T/H | 50,000-53,000 $ |

| CZLH678 | 4-20T/H | 74,000-76,000 $ |

| CZLH768 | 6-30T/H | 87,000-90,000 $ |

On average, a complete small-scale alfalfa pelletizing system suitable for small farms or start-ups can cost anywhere from 10,000 to 50,000 USD. Medium to large-scale alfalfa pelletizing systems designed for commercial production can range from 50,000 to 1,500,000 USD or more.

When considering the price, it's important to factor in the long-term benefits of investing in a high-quality machine. A durable and efficient alfalfa granulator can significantly reduce production costs, increase output, and improve the quality of the pellets, leading to higher profits in the long run.

To set up a complete alfalfa pellet production line, you will need more than just a granulator machine. Below is a list of the essential equipment required:

A hammer mill or grinder is used to reduce the dried alfalfa to a fine powder. This is a crucial step in preparing the alfalfa for pelletizing. If your raw materials are in bales or in haystacks, we will configure a bale breaker or shredder for you.

A conditioner is used to add moisture to the ground alfalfa before it enters the granulator. This step improves the binding properties of the alfalfa, resulting in better-quality pellets.

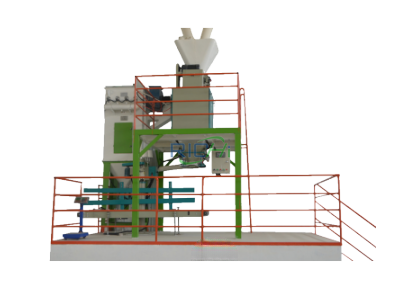

The alfalfa pellet making machine is the core equipment in the production line. It compresses and extrudes the conditioned alfalfa into pellets.

After pelletizing, the pellets need to be cooled to room temperature. A pellet cooler blows cool air over the pellets to harden and stabilize them.

A screening machine is used to remove fines and broken pellets, ensuring that only high-quality pellets are packaged.

Finally, a packaging machine is used to pack the alfalfa pellets into bags or store them in bulk. Proper packaging is essential to protect the pellets from moisture and contamination.

Conveyors and elevators are used to transport the alfalfa and pellets between different stages of the production process. They help to automate the process and reduce labor costs.

Storage silos are used to store the dried alfalfa and finished pellets. They protect the product from moisture, pests, and contamination.

Making alfalfa pellets with an alfalfa granulator machine is a highly efficient way to process and store this valuable forage crop. The process involves several steps, including harvesting, drying, grinding, conditioning, pelletizing, cooling, and packaging. The alfalfa granulator machine is a key piece of equipment in this process, offering features such as high compression ratio, adjustable die and roller gaps, durable construction, and easy maintenance.

Alfalfa pellets have a wide range of applications, from livestock and poultry feed to soil amendment. The price of an alfalfa granulator machine can vary depending on its capacity and features, but investing in a high-quality machine can lead to significant long-term benefits.

To set up a complete alfalfa pellet production line, you will need a range of equipment, including a hammer mill, conditioner, granulator machine, pellet cooler, screening machine, packaging machine, conveyors, and storage silos. With the right equipment and proper processing techniques, you can produce high-quality alfalfa pellets that meet the needs of your livestock and customers.

The alfalfa granulator machine is an essential tool for anyone looking to maximize the value of their alfalfa crop. By converting alfalfa into pellets, you can extend its shelf life, reduce storage space, and make it easier to handle and transport. Whether you are a small-scale farmer or a large-scale commercial producer, investing in an alfalfa granulator machine can help you achieve your production goals.

Alfalfa pellets have a wide range of applications, particularly in the livestock and agricultural industries. Below are some of the key uses:

Alfalfa pellets are a popular feed for cattle, horses, sheep, goats, and other ruminants. They provide a concentrated source of protein, fiber, and essential nutrients, making them an ideal supplement to traditional forage.

Alfalfa pellets can also be used as a feed for poultry, such as chickens and turkeys. They are rich in vitamins and minerals that promote healthy growth and egg production.

Alfalfa pellets are commonly used as a primary feed for rabbits, guinea pigs, and other small animals. They provide the necessary nutrients for these animals to thrive.

In addition to being used as animal feed, alfalfa pellets can also be used as a soil amendment. They are rich in organic matter and nutrients that improve soil fertility and structure. When used as a mulch or compost, alfalfa pellets can enhance plant growth and yield.

The global demand for alfalfa pellets has been steadily increasing due to the growing livestock industry and the need for high-quality animal feed. Alfalfa pellets are not only used as a primary feed for ruminants but also as a supplement for poultry, rabbits, and other small animals. Additionally, alfalfa pellets are used as a soil amendment in agriculture, further driving their demand.

The production of alfalfa pellets involves several steps, including harvesting, drying, grinding, conditioning, pelletizing, cooling, and packaging. The key piece of equipment in this process is the alfalfa granulator machine, which compresses and extrudes the alfalfa into pellets. The global market for alfalfa pellets is influenced by factors such as climate conditions, agricultural practices, livestock population, and economic development.

The prospects of processing alfalfa pellets across different continents are promising, driven by the growing demand for high-quality animal feed and the expansion of the livestock industry. Each region has its unique market potential, challenges, and opportunities, but the overall trend is towards increased production and consumption of alfalfa pellets.

Overall, the global market for alfalfa pellets is expected to continue growing, driven by the increasing demand for high-quality animal feed and the need for sustainable agricultural practices. By addressing the challenges and leveraging the opportunities, producers can maximize the potential of alfalfa pellet production and contribute to the growth of the livestock industry worldwide.

Richi Machinery provides pelleting plants and complete pelleting lines for the processing and production of alfalfa, grass, straw, hay pellets, etc. According to customers' requirements and construction features, our alfalfa granulator machines and alfalfa pelleting plants have different construction features and production capacity. Please feel free to contact us.

If you are interested in setting up alfalfa pellet machine plant and want to know the detailed cost of alfalfa and lucerne pellet production project, just contact us at RICHI for professional suggestions!

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.