This is where you find all our press releases and news articles.

In recent years, many countries and regions have vigorously promoted the comprehensive utilization of straw machinery and straw fertilizer, raw material, feed, base material, and energy in accordance with local conditions. This wave of actions once again drove the biomass pellet industry, including straw pellet machines.

Straw pellets are granular products made by crushing, compressing, and molding crop straw. Straw pellets have the characteristics of high density, easy storage and transportation, and high combustion efficiency, and are widely used in feed, fuel, and organic fertilizer. What kind of straw pellet machine do you know? Common straw pelletizers include rice straw pellet machine, paddy straw pellet machine, wheat straw pellet machine, corn straw pellet machine, concord straw pellets machine, cotton stalk pellet mill, etc.

Depending on their uses, straw pellets are mainly divided into the following categories:

The raw materials of straw pellets mainly come from crop straw. Common raw materials include:

In addition, the straw of other crops such as rapeseed, sugarcane, peanuts, etc. can also be used as raw materials.

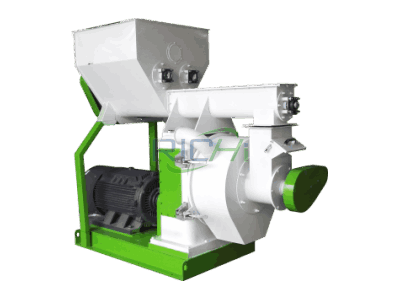

The straw pellet making machine uses crop straw or sawdust as the main raw material, and is pressed into cylindrical pellets by the straw pellet machine. Depending on the quality of the raw materials, the compressed pellets can be used as biomass fuel or as feed for livestock and poultry. The RICHI straw pellet machine absorbs the essence of the pellet machine and is a new energy-saving product.

In the past, the feed was generally processed into powder and then fed, but there were defects such as inconvenient feeding, poor palatability, picky eating by livestock, and low utilization rate. With the advent and popularization of new straw pellet machinery for feed, powder feed can be conveniently processed into pellet feed. It can use lighting electricity as power to press straw pellets from the die hole under the squeeze of the pressing roller, and the length of the straw pellets can be easily adjusted. The structure is simple, the floor space is small, and the noise is low.

The working principle of the straw pellet machine is to compact and squeeze raw materials such as straw, wood chips, rice husk, etc. out of the mold under the high temperature and high pressure environment of the pelletizing cavity through the extrusion and friction generated during the movement of the ring die and the pressing roller. Holes, and finally form a regular, denser fuel. Ring die and pressure roller are the core components of the straw pellet machine equipment. The ring die and material feeding are arranged horizontally relative to the whole straw pellet machine. The powder material of the horizontal straw pellet machine is fed vertically from the front end of the granulating cavity (with the help of the fan. Forced feeding), the ring die and the straw pelletizing unit are arranged vertically.

At present, the straw pellet machine products of various manufacturers have differences in the core work component structure, the technical route of the whole machine, and the design of product efficiency, and the reliability of similar straw pellet machine products has a large gap. The service life of the straw pellet machine ring die and the pressing roller is relatively short, and the frequency of maintenance and replacement is high, which is the main reason for the high cost of the straw pellet machine. It is recommended that when purchasing the ring die and pressure roller of the ring die straw pellet machine, you must choose a manufacturer with excellent technology and a certain scale.

| Model | MZLH320 Straw Pellet Machine | MZLH350 Straw Pellet Machine | MZLH420 Straw Pellet Machine | MZLH520 Straw Pellet Machine | MZLH768 Straw Pellet Machine | MZLH858 Straw Pellet Machine |

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Straw Pellet Machine Power | 37KW | 55KW | 90KW | 132KW | 250KW | 280KW |

| Straw Pellet Capacity | 600-800KG/H | 800-1000KG/H | 1.5-2 T/H | 3-4 T/H | 5-7 T/H | 8-10 T/H |

| Final Straw Pellet Size | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Straw Pellet Machine Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

The processing flow of straw feed pellets mainly includes the following steps:

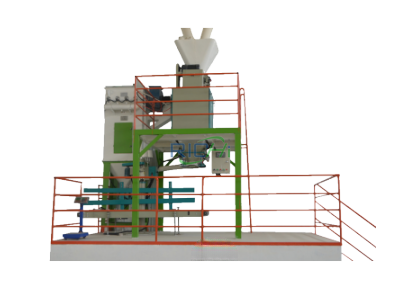

The following equipment is required for processing straw feed pellets:

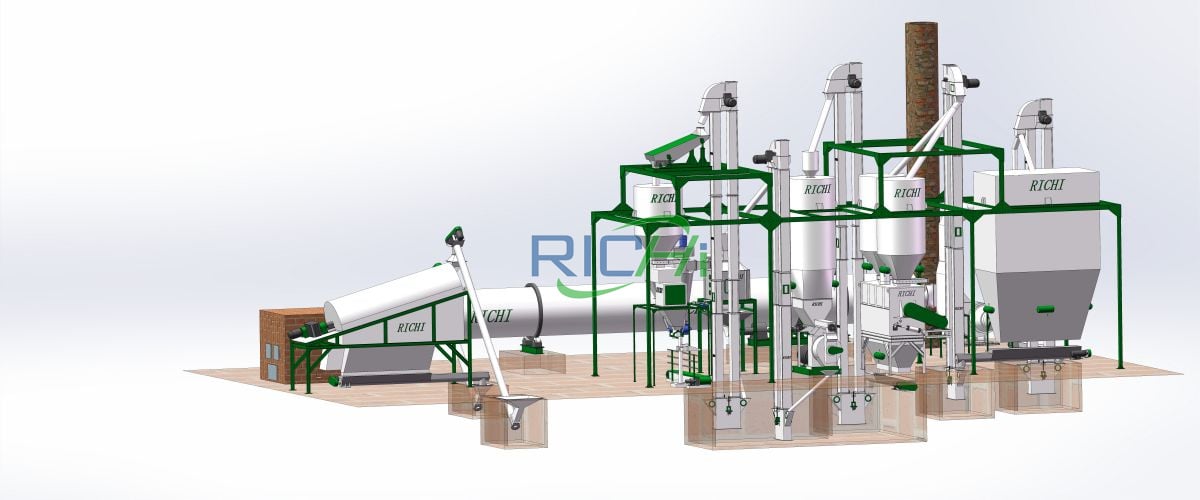

The processing process of straw fuel pellets is similar to that of feed pellets, but there are some key differences:

The following equipment is required for processing straw fuel pellets:

The processing process of straw organic fertilizer pellets is different from the previous two pellets, mainly adding a fermentation step:

The following equipment is required for processing straw organic fertilizer granules:

Although the processing procedures of the three types of straw pellets are similar and the processing equipment has some overlap in function, there are some differences in the specific process and specific configuration:

Focus on the nutritional content of the raw materials, and usually need to add other feed raw materials (such as soybean meal, corn flour, etc.) to improve the nutritional value. The hardness and density of the pellets are required to be high during the processing to facilitate animal digestion. In the process of processing straw feed pellets, a mixer is required to add other feed raw materials, and the pellet machine needs to have a high compression capacity to ensure the hardness and density of the pellets.

Focus on the calorific value and combustion efficiency of the raw materials, and usually require a low moisture content of the straw (below 10%). The density and combustion performance of the pellets are required to be high during the processing. In the process of processing straw fuel pellets, a dryer is required to reduce the moisture content of the straw, and the pellet machine needs to have a high compression capacity to ensure the density and combustion performance of the pellets.

Focus on the organic matter content and fermentation effect of the raw materials, and usually need to be fermented. The processing process has high requirements for the organic matter content and nutrient release rate of the pellets. In the process of processing straw fertilizer, fermentation equipment is required for fermentation treatment, and the pellet machine needs to have a high compression capacity to ensure the organic matter content and nutrient release rate of the pellets.

The processing costs of the three types of straw pellets are different, mainly reflected in the following aspects:

Raw material cost: Feed pellets usually need to add other feed raw materials, so the raw material cost is higher; the raw material cost of fuel pellets and organic fertilizer pellets is relatively low. Equipment cost: The equipment cost of feed pellets and fuel pellets is relatively low, while organic fertilizer pellets require additional fermentation equipment, so the equipment cost is higher. Energy consumption cost: A lot of drying treatment is required during the processing of fuel pellets, so the energy consumption cost is high; the energy consumption cost of feed pellets and organic fertilizer pellets is relatively low.Overall, the processing cost of straw feed pellets and straw fuel pellets is relatively low, while the processing cost of straw fertilizer pellets is high.

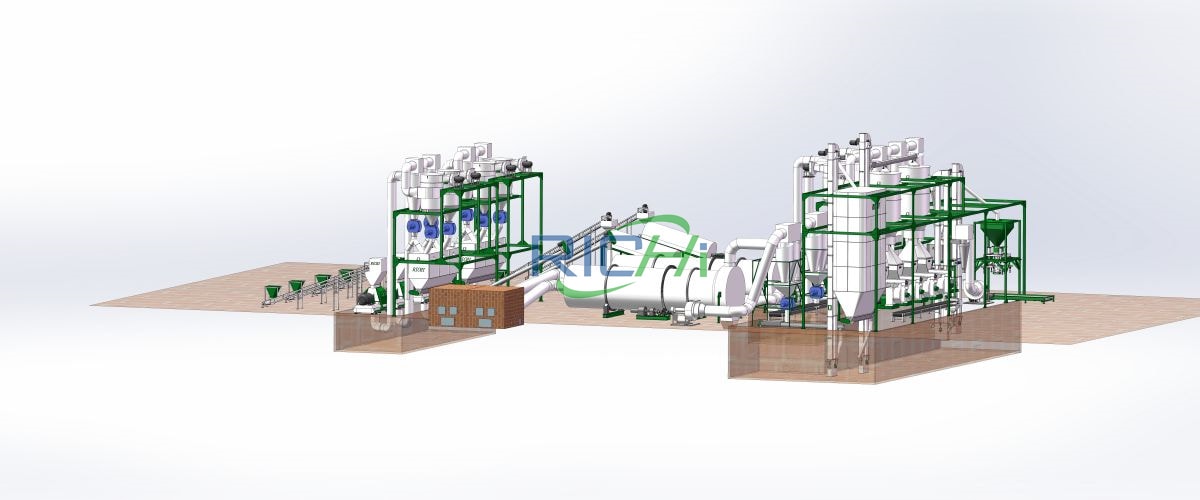

The following steps need to be considered when building a straw pellet production line:

The cost of building a straw pellet production line mainly includes the following aspects:

In general, the cost of building a small or medium-sized straw pellet production line is about several million yuan, and the specific cost needs to be estimated in detail according to the actual situation.

Straw pellet processing is an industry with broad market prospects. It can not only effectively utilize crop straw resources, but also provide high-quality products for feed, fuel and organic fertilizer. Through reasonable equipment selection and process design, straw pellet processing can achieve efficient and environmentally friendly production and contribute to the sustainable development of agriculture.

Straw pellet fuel is a circular economy and environmental protection project encouraged and supported by various countries. It is suitable for promotion and use in small, medium and small towns and rural areas. The product market is broad, the source of raw materials is sufficient, the process technology is mature, and the CE high quality straw pellet machine equipment is advanced and reasonable; the straw pellet machine project investment recovery period is short and the return The rate is high, and there is a strong ability to resist risks.

Straw feed pellets are used to feed cattle and sheep, the feed intake rate can reach 100%, the digestion and absorption rate can be increased by more than 60%, the milk production of dairy cows can be increased by more than 10%, and the weight gain of beef cattle can be increased by more than 15%. At the same time, the straw is processed into pellets. Feed can turn the abandoned crop straw into a commodity that can be transported and stored for a long time, improve the utilization level of crop straw, realize the commercial production and off-site digestion and utilization of crop straw, increase the value of straw, increase farmers' income, and promote agriculture. Animal husbandry has developed and protected the ecological environment.

Please feel free to contact RICHI MACHINERY for details on the price, pictures, videos and other equipment of the competitive price straw pellet machine for best price straw pellet production line.

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.