This is where you find all our press releases and news articles.

The Lucerne Pellet Machine is a revolutionary piece of equipment designed to transform raw Lucerne (alfalfa) and other forage materials into high-quality pellets. These pellets are widely used in animal feed, fuel, and other industrial applications.

With increasing demand for sustainable and efficient feed solutions, the Lucerne Pelleting Machine has become a vital tool for farmers, feed producers, and entrepreneurs across Africa, Asia, Europe, and America. Here, RICHI Machinery will provide you a detailed overview of the Lucerne Pellet Machine, its applications, technical features, and market potential.

The Lucerne Pellet Machine is a specialized pellet mill designed to process Lucerne (alfalfa) and other forage materials into compact, nutrient-rich pellets. These machines are engineered to handle high-capacity production while maintaining consistent pellet quality. They are widely used in the animal feed industry, particularly for livestock such as cattle, sheep, and horses, due to the high nutritional value of Lucerne pellets.

The Lucerne Pellet Mill Machine (alfalfa pellet making machine) is primarily designed for processing Lucerne (alfalfa), but it can also handle a variety of other raw materials, including:

The versatility of the machine allows for the production of mixed feed pellets, combining Lucerne with grains or other forage materials to enhance nutritional value.

To better understand the functionality and efficiency of the Lucerne Pellet Making Machine, you can watch our detailed video demonstration. The video showcases the machine in action, highlighting its key features, operational process, and final pellet output.

The Ring Die Lucerne Pellet Machine is a high-performance model known for its durability and efficiency. Key features include:

The Lucerne Pellet Processing Machine operates on the principle of compression and extrusion. The raw materials are fed into the machine, where they are compressed by rollers against a rotating ring die. The pressure and heat generated during this process bind the materials together, forming dense, cylindrical pellets. These pellets are then cut to the desired length and discharged for cooling and packaging.

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch feeder power (kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced feeder power (kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring die inner diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished pellet diameter (mm) | 4~12 | |||||

| Output(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

The Lucerne Pellet Machine cost varies depending on the model, capacity, and additional features. On average, the cost ranges from 8,000 to100,000. For an accurate quote, please contact RICHI MACHINERY directly.

The equipment quotation Including : anti-arching feeder, conditioner, force feeder, pelletizer, control cabient.

RICHI MACHINERY has successfully delivered Lucerne Pellet Manufacturing Machines to numerous clients worldwide. Some notable projects include:

Lucerne Pellet Machine For Sale South Africa

Lucerne Pellet Machine For Sale Mexico

Lucerne Pellet Machine For Sale Russia

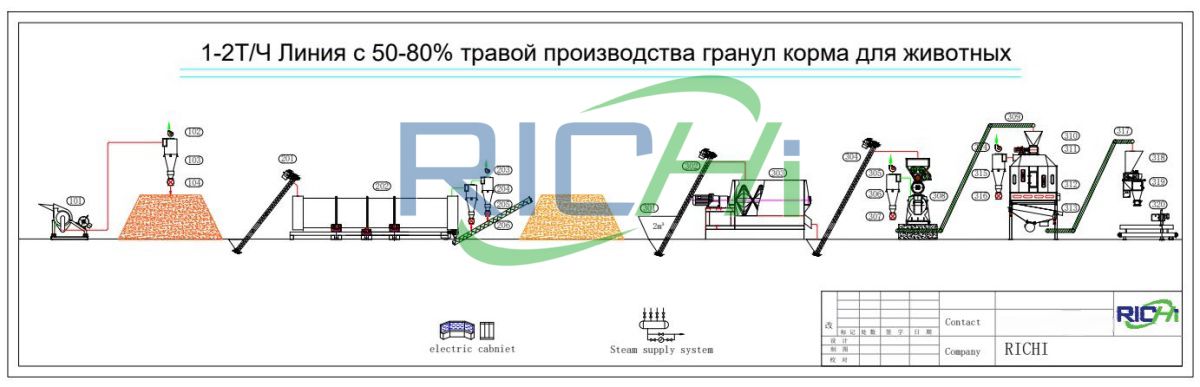

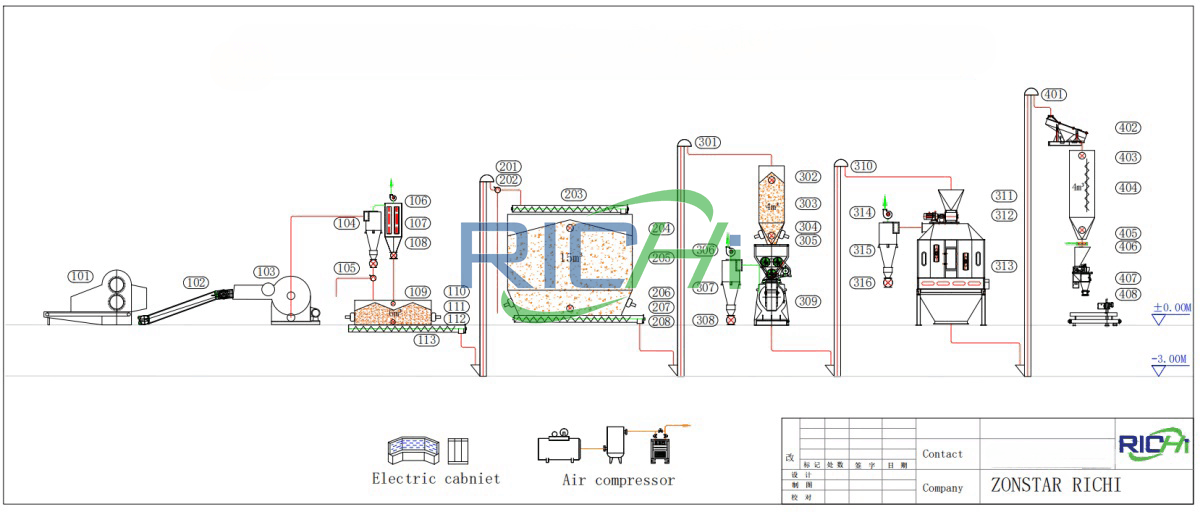

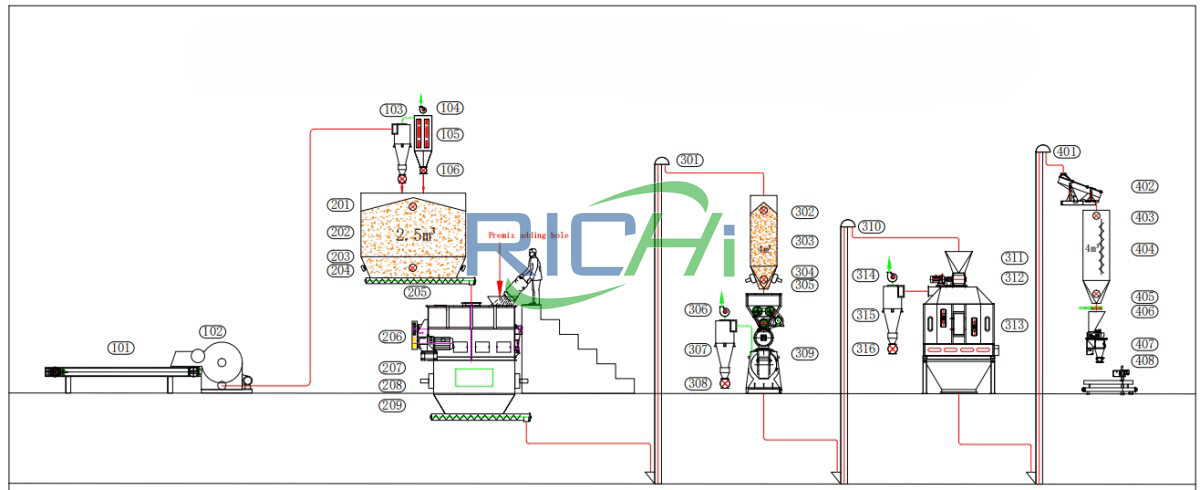

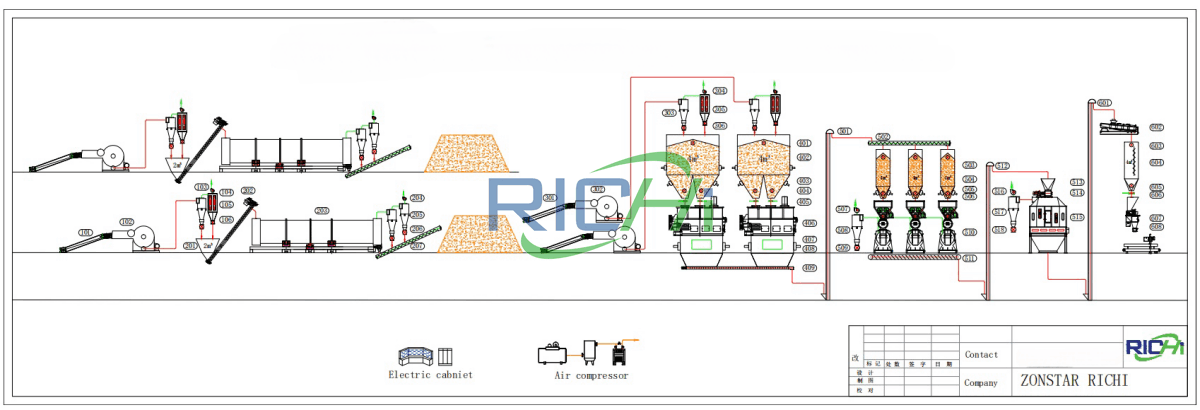

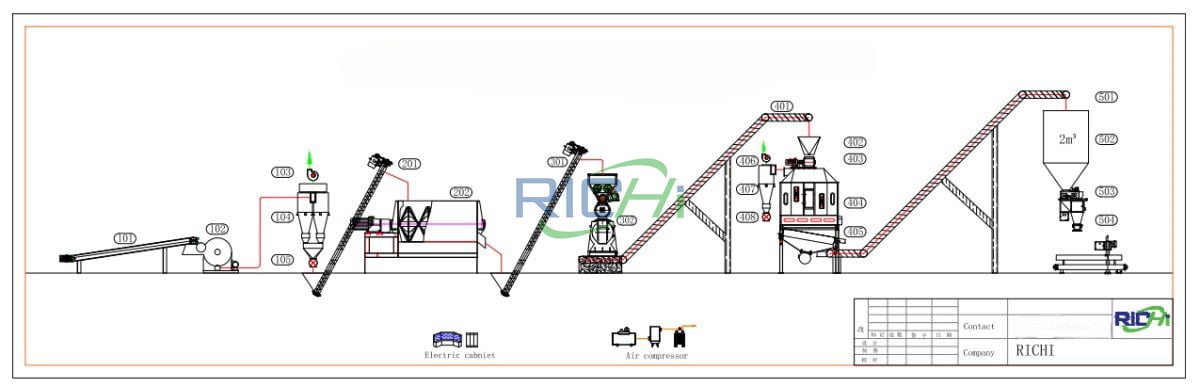

The complete process of producing Lucerne pellets involves the following steps:

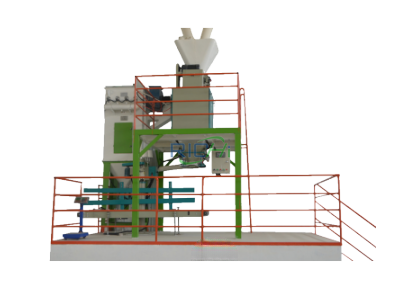

RICHI MACHINERY offers customized Lucerne Alfalfa Pellet Production Line solutions to meet specific production requirements. Factors such as desired output, raw material availability, and budget are considered when designing a Lucerne pellet plant. Our team works closely with clients to ensure optimal plant configuration and efficiency.

A complete Lucerne pellet plant includes the following key equipment:

The cost of a full Lucerne pellet plant depends on the scale and configuration. A small-scale plant may cost around 20,000-50,000,while a large−scale plant can exceed 200,000. Contact RICHI MACHINERY for a detailed quotation.

The plant cost including weighing system , hammer mill, mixer .....

For more information or to request a quote, contact RICHI MACHINERY today!

The purpose of processing Lucerne Pellets is to convert the original alfalfa into a form that is more efficient, easier to store and transport, while retaining its nutritional value. Here are the main reasons for processing alfalfa pellets:

Lucerne itself is rich in protein, vitamins and minerals, but by processing it into pellets, these nutrients can be better retained while improving digestion and absorption.

The original lucerne is large in volume and low in density, and the storage and transportation costs are high. After being processed into pellets, the volume is reduced and the density is increased, which greatly reduces the storage and transportation costs.

After drying and compression, alfalfa pellets have low moisture content, are not easy to mold and deteriorate, and have a longer shelf life than raw alfalfa.

Lucerne in pellet form is easier for animals to eat, reducing waste, and can be mixed with other feed ingredients to improve the overall nutritional value of the feed.

With the development of animal husbandry and feed industry, the market demand for high-quality and standardized feed is increasing, and alfalfa pellets just meet this demand.

Lucerne is a sustainable crop. After being processed into pellets, it can be used as environmentally friendly feed or fuel, reducing the burden on the environment.

Lucerne pellets can be used as biomass fuel for power generation or heating, and are a renewable energy source.

Lucerne pellets can be used as organic fertilizer to improve soil structure and increase soil fertility.

Lucerne pellets are in high demand in the international market, especially in countries with developed animal husbandry but insufficient alfalfa production (such as China and the Middle East).

Lucerne pellets can be used as feed for herbivorous pets such as rabbits and guinea pigs, providing necessary nutrition.

In some cases, lucerne pellets can be used as a supplemental ingredient in aquaculture feeds to provide plant protein and fiber.

Processing Lucerne Pellets not only improves the utilization efficiency of alfalfa, but also expands its application range. Whether as a high-nutrition animal feed, biomass fuel, or soil conditioner, alfalfa pellets have demonstrated their huge economic value and environmental significance.

With the growing global demand for high-quality feed and renewable energy, the market prospects of alfalfa pellets will be even broader.

The global demand for Lucerne pellets is growing due to their nutritional benefits and versatility. The animal feed industry, in particular, is driving this demand, with increasing adoption in Africa, Asia, Europe, and America.

Reason: The United States is one of the world's largest producers of alfalfa, with advanced agricultural technology and a mature feed market. Alfalfa pellets, as a high-nutrition feed, are in great demand in the US livestock industry, especially in dairy and beef cattle farming.

China is one of the world's largest feed consumers. With the scale of livestock farming and the increasing demand for high-quality feed, the market potential of alfalfa pellets is huge. In addition, China's dependence on imported alfalfa has also promoted the development of the local alfalfa processing industry.

India has a large livestock industry and a rapidly growing demand for feed. Alfalfa pellets, as a high-protein feed, are very suitable for India's dairy and buffalo farming industries. In addition, India's climatic conditions are suitable for alfalfa cultivation.

Australia is a major producer and exporter of alfalfa, with a well-developed livestock industry, especially cattle and sheep farming. Alfalfa pellets are in high demand in both the domestic and international markets in Australia.

Spain is a major alfalfa producer in Europe, and its warm climate is suitable for alfalfa cultivation. Alfalfa pellets are widely used in the livestock industry in Spain and are also exported to other European countries.

Argentina is the main alfalfa producer in South America, and its livestock industry is large, especially the beef and dairy industries. Alfalfa pellets, as a high-nutrition feed, are in high demand in Argentina and the international market.

South Africa's livestock and feed industries are developing rapidly. Alfalfa pellets, as high-quality feed, have broad market prospects in South Africa's cattle and sheep farming industry. In addition, South Africa's climatic conditions are suitable for alfalfa cultivation.

France is an important livestock country in Europe, and its dairy farming industry has a high demand for high-quality feed. Alfalfa pellets occupy an important position in the French feed market and are also exported to other European countries.

Egypt's livestock and feed industries are developing rapidly, but due to limited water resources, alfalfa, as a drought-resistant crop, is very suitable for local cultivation. Alfalfa pellets have great potential in Egypt's feed market.

Brazil is an important agricultural country in the world, with a large livestock industry, especially beef and poultry industries. Alfalfa pellets, as high-protein feed, are in great demand in the Brazilian feed market.

Investing in alfalfa pellet processing industry in these countries can not only meet local market demand, but also obtain greater economic benefits through export.

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.