This is where you find all our press releases and news articles.

How to process tofu cat litter? Let's first look at the standard tofu cat litter production process:

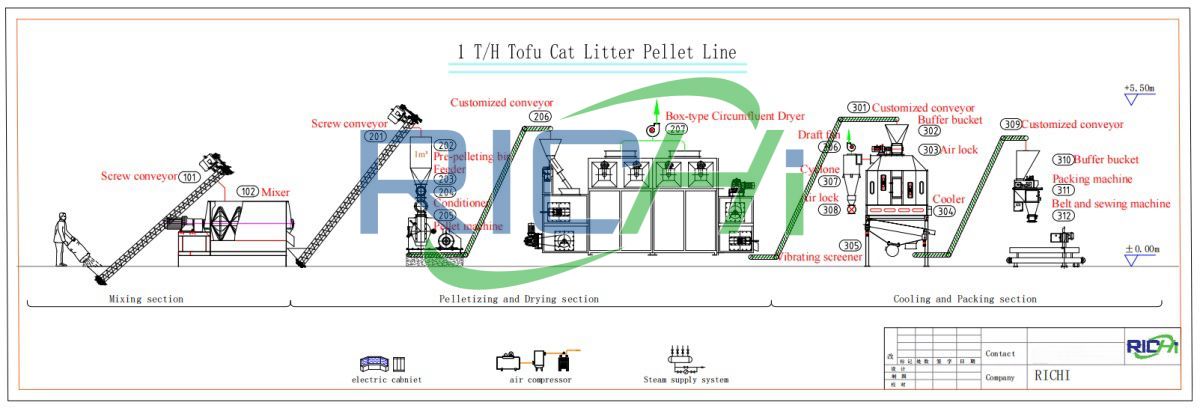

The above is the common process flow of tofu cat litter processing equipment. Different manufacturers may be different, but the general process is similar. Next, we will further understand "how to process tofu cat litter" based on the process of a 1-ton-per-hour Malaysia tofu cat litter production line we have made.

This is a typical tofu cat litter processing process. The raw materials of this customer are all powdered. Therefore, there is no need to crush them. All the raw materials are put into the mixer according to the ratio. The mixed powder is transported to the cat litter pellet machine.

After granulation, the cat litter pellets enter the belt dryer and then the cooler. The screening machine of this project is set below the cooler. After the cooled cat litter pellets are screened by the vibrating screen, the qualified particles enter the packaging section, and the unqualified particles will be re-granulated.

It should be emphasized that the process flow of the cat litter plant project undertaken by RICHI MACHINERY is all customized because the raw materials, formulas, plant structure and area, special needs and investment budgets of customers are different.

If you want to carry out tofu cat litter processing, bentonite cat litter processing, waste paper cat litter processing, wood pellet cat litter processing, zeolite cat litter processing, diatomaceous earth cat litter processing, crystal cat litter processing, attapulgite cat litter processing or other types of cat litter product processing, feel free to contact us to customize the cat litter processing process flow, get a full set of equipment configuration and quotation, plant layout and construction plan!

In order to let you better understand how to process tofu cat litter and how to build a tofu cat litter plant, below, we will list two of our projects for you, one is the 10t/h Kazakhstan tofu cat litter production line project, and the other is the Russian 16-17 tons tofu cat litter processing project. I hope you can learn more about tofu cat litter processing business from these two projects.

Below are some of the featured cat litter factory projects we have done. You can also go directly to our case center to view more cat litter project information!

Cat litter is a must for indoor cats, but outdoor-venturing cats will also appreciate a readily available tray filled with clean litter. The best cat litter and litter trays give your kitty a hygienic, private and convenient toilet in the comfort of their own home, whatever the weather. Cat litter comes in a huge variety of types, some of which will suit your cat and some of which won't. What all cats do have in common is fastidious cleanliness, so they'll always appreciate a carefully-cleaned, freshly-filled tray. Without it, accidents can occur, especially if your cat is very young or old, or hasn't been well.

According to different formulas and materials, tofu cat litter has been researched and developed by engineers and technicians. The cost of cat litter is also based on different formulas to make different levels of cat litter, and the price is also quite different. Depending on the recipe of cat litter, the processing cost of cat litter is also different. The quality and formula of cat litter are the main constraints to the cost of cat litter.

With the improvement of people's quality of life and the development of an aging society, cats have become our favorite members. The reason is very simple. Cats are small, clean, cute, docile, and easy to take care of. In the future, cats in the pet market will be It is an exponential growth, and now, in the pet market of 100 billion level, cat litter, as a pet product, has been walking on the edge of the industry for a long time.

From 15 years to 20 years, cat litter can be said to be explosive growth, but There are still various problems in this industry, such as quality standards, technical formulas, production equipment, etc., all of which are developing backwards...

Richi Machinery provides a full set of cat litter factory equipment for production, installation, commissioning, and free trial machines, design the tofu cat litter production line for free. Our tofu cat litter factory and cat litter production line can process cat litter pellets of 1.2-6mm, and the pellet length can be adjusted according to needs.

This is a tofu cat litter factory in Kazakhstan project. The client is a pet food company. Based on the good development prospects of the pet products industry, the client decided to invest 430,000 US dollars to build a cat litter production line project with an annual output of 50,000 tons. The project produces 10 tons of tofu cat litter per hour.

The cat litter factory in Kazakhstan project produces 50,000 tons of cat litter per year. The project covers an area of 2,000 square meters (3 acres) and a total construction area of 2,000 square meters. The main construction area includes 2,000 square meters of factory buildings, 1,000 square meters of raw material and finished product warehouses, and 200 square meters of office areas.

This project will build 2 production lines in two phases. After the project is completed, it will produce 50,000 tons of cat litter per year. The project has a labor quota of 20 people, 300 working days per year, and adopts a two-shift 16-hour work system. The composition of the project is shown in the following table:

| Main engineering | Production workshop 2000 square meters. |

| Storage and transportation engineering | Raw material and finished product warehouse 1000 square meters. |

| Auxiliary engineering | Office area 200 square meters. |

The main raw and auxiliary materials of this cat litter factory in Kazakhstan project are wheat flour, corn flour, tofu residue, etc. The project area has a well-developed transportation network, and raw and auxiliary materials can be purchased locally and in surrounding cities.

The market supply is sufficient to meet the production needs of the project. The consumption of raw and auxiliary materials is shown in the table below.

| No. | Name | Unit | Annual Usage | Storage Method |

| 1 | Wheat middlings | t | 10200 | Bagged, 25kg/bag |

| 2 | Corn middlings | t | 7650 | bag, 20kg/bag |

| 3 | Starch | t | 5100 | Bag, 25kg/bag |

| 4 | Bamboo powder | t | 5100 | Bag, 25kg/bag |

| 5 | Tofu residue | t | 20400 | Bag, 25kg/bag |

| 6 | Other auxiliary materials | t | 2550 | Box, 25kg/box |

The main production equipment of the two phases of this cat litter factory in Kazakhstan project is the same, see the table below for details.

| Serial number | Equipment name | QTY |

| 1 | Crusher | 2 |

| 2 | Feed hopper | 2 |

| 3 | Pulse dust collector | 2 |

| 4 | 1# Bucket elevator | 2 |

| 5 | Pneumatic tee | 2 |

| 6 | Mixer | 4 |

| 7 | 2# Bucket Elevator | 2 |

| 8 | Permanent Magnetic Cylinder | 2 |

| 9 | Pelletizing Bin | 2 |

| 10 | Controller | 2 |

| 11 | Cat Litter Pelletizing Machine | 2 |

| 12 | Scraper Conveyor | 8 |

| 13 | Air lock | 4 |

| 14 | Flap cooler | 4 |

| 15 | Fan | 4 |

| 16 | Cyclone dust collector | 6 |

| 17 | Air lock | 4 |

| 18 | Drying box | 2 |

| 19 | Flat rotary screen | 4 |

| 20 | Pulse dust collector | 16 |

| 21 | Power distribution cabinet | 2 |

| 22 | Packaging machine | 3 |

| 23 | Air compressor | 2 |

The water used in the cat litter factory in Kazakhstan project is provided by the local water supply system, and the water quality and quantity can meet the needs of the project. The project needs water in the production process, and the water consumption is 1.5m3/d, which is all used in the product, and no production wastewater is generated; no greening water is used.

The project has a labor quota of 20, and the living water consumption is calculated as 40L/person·d, and the water consumption is 0.8m3/d. Therefore, the fresh water consumption of the project is 2.3m3/d.

The electricity used in this project is provided by the local power supply system, and the voltage and power can meet the needs of the project.

The heat used for production in this cat litter factory project is provided by an electric heating furnace, and air conditioning is used for office and living heat in winter. No boiler is installed.

In this cat litter factory in Kazakhstan project, how to process tofu cat litter? According to the customer's raw materials and needs, RICHI engineers designed the cat litter processing process for the customer as follows:

Here is a project report for a large 16-17t/h cat litter factory we have done in Russia. In order to meet market demand, the client invested 650,000 USD to build a new tofu cat litter pellet plant with an annual output of 80,000 tons, using soybean fiber, corn flour, walnut wood, and water as raw materials, through ingredients, mixing, granulating, and drying, screening, packaging and other processes. After the cat litter factory completion, it will produce 40,000 tons of tofu cat litter and 40,000 tons of plant cat litter.

(By bidding, RICHI undertakes the construction of the cat litter pellet production line project with an annual output of 40,000 tons, plant cat litter production line provided by a other cat litter making machine manufacturer. )

| Items | Engineering composition | Cat Litter Factory Construction Content |

| Structural work |

1# production workshop |

It has 3 floors and covers an area of 3876m². Set up 1 cat litter production line, install elevators, mixers, cat litter pellet machines and other cat litter machines. The warehouse in the northeast corner of the workshop is mainly used to store raw materials and finished products, and the office area (3rd floor) is set on the west side of the workshop |

| # 2 production workshop |

It has 3 floors and covers an area of 3876m². Set up 1 cat litter production line, install elevators, mixers, cat litter making machine and other equipment, and set up an office area (3rd floor) on the west side of the workshop. | |

| # 3 production workshop |

3 floors, covering an area of 6450m². Set up 2 cat litter pellet production lines, install elevators, mixers, cat litter pellet machine and other cat litter manufacturing machine. | |

| Auxiliary engineering |

switch room | 15 m², equipped with 400kVA transformer |

| extinguiser pool | 1500m³, located in the underground of the west side of 1# production workshop | |

| guard room | There are two 1-story buildings, each with a construction area of 20m². | |

| Public works |

water supply | The water for the project is provided by the park's water supply pipe network, and the annual fresh water consumption is 420m³/a. |

| powered by |

The power supply pipe network of the project power park is provided. A 400kVA transformer is installed in the plant area and the annual power consumption is 8 million kW·h. | |

| Heating | The heat source of the pelletizing process and drying process of the project is provided by outsourcing steam; the office area is heated by air conditioning in winter. | |

| Environmental Engineering |

Exhaust |

1# production workshop feed waste gas is collected by the gas hood and sent to the bag filter for treatment, the drying waste gas is collected under negative pressure to the bag filter for treatment, and 2 waste gas is discharged through a 15m high exhaust pipe (P1) |

| 2# production workshop feed waste gas is collected by the gas hood and sent to the bag filter for treatment, the drying waste gas is collected under negative pressure to the bag filter for treatment, and 2 waste gas is discharged through a 15m high exhaust gas cylinder (P2) | ||

| Workshop # 3 each production line by feeding the exhaust gas to the collection hood collecting bag dust collector, and drying the exhaust gas collected in the baghouse vacuum process, two exhaust gas lines 4 via a femoral 15m high exhaust tube ( P3) | ||

| Waste water |

The large scale cat litter factory project wastewater is mainly steam condensate and domestic sewage. Part of the steam condensate is reused in the batching process, and the remaining part is returned to the original heating company for reuse. The domestic sewage plant is splashed with dust to suppress dust. The tofu cat litter manufacturing plant is equipped with anti-seepage dry toilets and cleaned regularly , Used as agricultural fertilizer. | |

| noise | Use low-noise auto cat litter machine, basic vibration reduction, plant sound insulation, fan silencers and other measures. | |

| Solid waste |

Unqualified products: After centralized collection, they are returned to production. | |

| Dust removal ash: After centralized collection, it is reused for production. | ||

| Domestic garbage: After centralized collection, it will be handed over to the local sanitation department for unified disposal. |

| Serial number | name | Dosage | unit | Remarks | |

|---|---|---|---|---|---|

| 1 |

Tofu cat litter | Soybean fiber |

17000 |

t/a |

100kg / bags, coarse particles with beany gas, temporarily stored in the warehouse |

| 2 |

Walnut |

13000 |

t/a |

100kg/bag, foam wood chips, temporarily stored in the warehouse |

|

| 3 | corn flour | 10000 | t/a | Bagged, temporarily stored in the warehouse | |

| 4 | water | 2000 | m3 / a | Reuse steam condensate | |

| 5 | Electricity | 400 | Million kW · h / a | Provided by the local power supply network | |

| Number | Name of cat litter manufacturing machine | Specification | Unit | Quantity |

| 1 | Hoist | - | station | 16 |

| 2 | Cat litter mixer | - | station | 4 |

| 3 | cat litter pellet making machine | - | station | 8 |

| 4 | Bucket elevator | 4m | station | 8 |

| 5 | Drying warehouse | - | station | 4 |

| 6 | Vibrating screen | 50kw | station | 4 |

| 7 | Finished silo | - | station | 20 |

| 8 | Cat litter bagging machine | - | station | 4 |

| total | 68 | |||

The 16-17tph Russia automatic tofu cat litter pellet production line project uses soybean fiber, walnut wood, corn flour, water, etc. as the main raw materials to produce cat litter through batching, mixing, granulating, drying, screening, and packaging. After the whole cat litter manufacturing palnt project is completed, it will produce 40,000 tons of tofu cat litter and 40,000 tons of plant cat litter.

The production process of tofu cat litter is the same as that of plant cat litter, only the ratio of raw materials is different. This cat litter factory project has a total of 4 kitty litter pellet production lines with the same production process and capacity.

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.