This is where you find all our press releases and news articles.

How to Make Grass Pellets For Feed? The core equipment is the grass pellet machine, and the core process is the processing flow of grass pellets.

According to the physical properties of grass raw materials (grass powder/haystack/long size/high moisture/impurities) and the raw material ratio (pure grass/grass & grains/grass & other biomass), we will configure suitable grass pellet processing equipment and grass pellet processing technology for customers.

Below, let RICHI MACHIINERY introduce you in detail our grass pellet machine and grass pellet processing technology, as well as auxiliary equipment for grass pellet processing.

A grass pellet machine is a type of feed pellet machine, which is mainly used to process materials with grass as the main raw material into ruminant feed such as cattle and sheep, as well as livestock feed pellets and poultry feed pellets.

Grass pellet mills can not only process a single grass or a mixture of multiple grasses into feed pellets, but also a mixture of grass and grains, a mixture of various straws and grains, and a mixture of grass, straw and grains into feed pellets for feeding different types of animals.

RICHI has been committed to the research and development, manufacturing, production and sales of grass pellet mills. The grass pellet mills produced by RICHI are used in various small, medium and large feed processing plants, greatly improving the efficiency of grass pellet feed production and the quality of feed pellets.

Grass pellet mills are mainly used to process different types of grass, such as alfalfa, hay, clover, nettle grass and other types of grass into feed pellets. In addition to 100% grass pellets, your formula may also contain grains such as corn and wheat, or raw materials such as straw, buckwheat husks, cotton husks, and sunflower husks.

Grass pellet mills can meet the production needs of all feed formulas. In addition to processing 100% grass into feed pellets, they can also process a mixture of grass and grains, a mixture of grass and straw, and a mixture of grass, straw and grains.

For areas with large grass planting areas, using a grass pellet mill to process grass into feed pellets is a very promising and profitable business.

Grass feed pellets pressed by a grass pellet mill are a source of food and nutrition for many animals. Grass feed pellets can be used for all types of ruminants such as cattle and sheep that mainly feed on grass, such as dairy cows, bulls, calves, goats, sheep, etc., and can also be used to feed many other types of poultry and livestock, such as pigs, chickens, camels, etc.

As a substitute for grass, grass pellets are widely used in various types of livestock farms and farms for their rich nutrition, good chewing, strong palatability, improved feed conversion rate, easy transportation, and convenient storage.

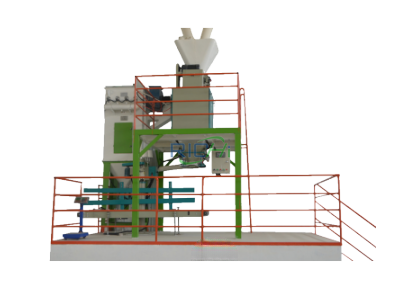

RICHI forage pellet mill adds a forced feeding device on the basis of the original feed pellet mill. The specially designed forage pellet mill can effectively improve the pelleting efficiency and production capacity.

In addition, the forage pellet mill uses high-quality raw materials in the manufacturing process, and the parts are world-renowned brands, providing customers with high-quality feed pellet production equipment. The following is a detailed display of RICHI forage pellet mill:

The variable frequency feeding device with anti-caking device can effectively reduce the arching of raw materials and improve production efficiency.

The main transmission method adopts high-precision gear transmission, and the production effect can be improved by about 15%.

The serpentine spring coupling with international advanced level is used, which has novel structure, compact structure, low failure rate and other performances.

Many innovative designs are made in many aspects such as anti-cracking of ring die, increased hourly output and increased total output.

The modulator is made of 304 stainless steel, including the internal shaft and paddles, which can package the quality of finished feed pellets.

The main motor of the forage pelletizer uses Siemens motor, which can extend the service life of the entire pelletizer.

RICHI forage pelletizer can process powdered forage, straw, small grain or their mixture into feed pellets.

During the production process, the grass powder and grain after crushing and mixing enter the modulator through the feeder. In the modulator, the material is fully in contact with steam. After high temperature and high pressure, the material is matured and sterilized, and then enters the pelletizing chamber under the action of the forced feeder.

In the pelletizing chamber, the material is compacted and squeezed into the die hole of the ring die by the pressing action of the ring die and the roller. The cylindrical particles formed in the die hole are extruded and then cut into feed pellets of the required length by the cutter.

The support beam and main shaft of the whole equipment of RICH forage pelletizer are forged into one piece. The gap between the roller and the ring die can be kept uniform, which can effectively ensure the production efficiency of the whole equipment.

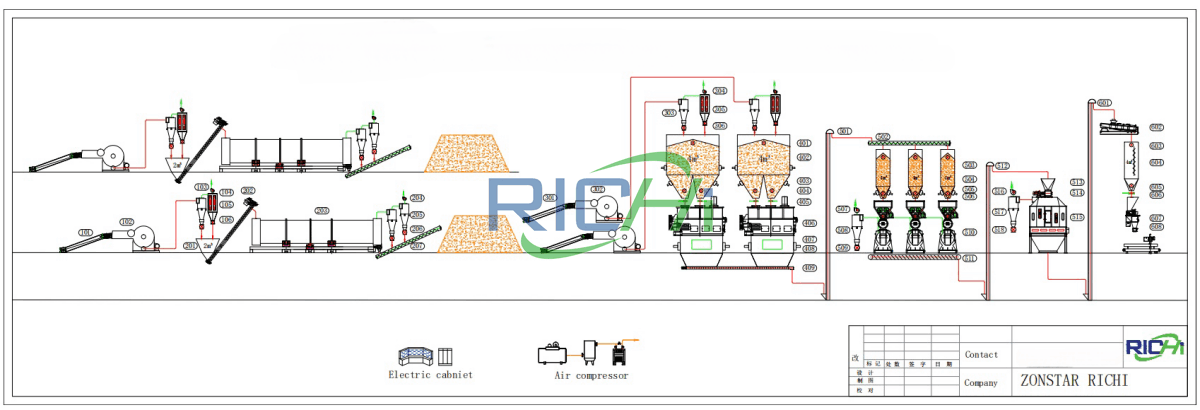

The output of common forage pellet mills is between 0.5-8 tons per hour, which is also the equipment that many customers often purchase from us. In addition to providing 0.5-8 tons per hour forage pellet mills and 0.5-10 tons per hour forage feed pellet production equipment, RICHI can also provide customers with large-volume forage pellet production solutions according to customer demand for output, such as 15 tons per hour forage pellet production line, 20 tons per hour forage pellet production line, 30 tons per hour forage pellet production line, etc.

To learn more about the detailed parameters and prices of grass pellet mills and forage feed production lines, please contact us directly. As a leading feed production equipment manufacturer in the industry, RICHI can provide you with suitable forage feed production equipment with rich experience. (The output of the following grass pellet mills is only the output of processing 100% pure grass pellets. If there are grains and various additives in the formula, the output will increase. The larger the proportion of grains and cereals, the greater the output of the pellet mill.)

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch feeder power (kw) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced feeder power (kw) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring die inner diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished pellet diameter (mm) | 4~12 | |||||

| Output(T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

For commercial forage feed pellet production, in addition to the need for a forage pelletizer, a complete forage feed production plan is also required. RICHI can not only provide professional forage pelletizers, but also provide a complete set of forage feed pellet production line solutions.

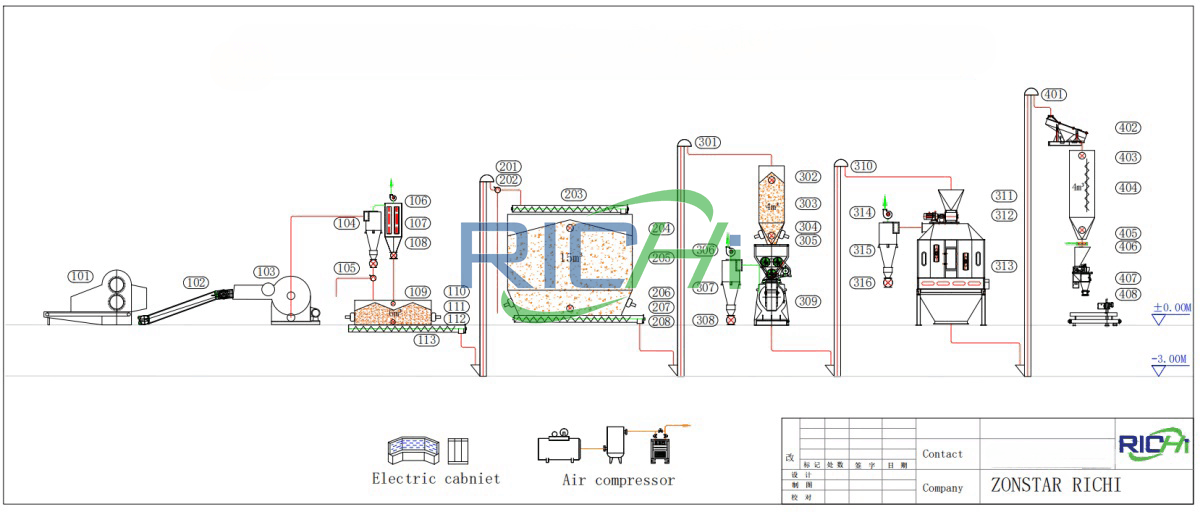

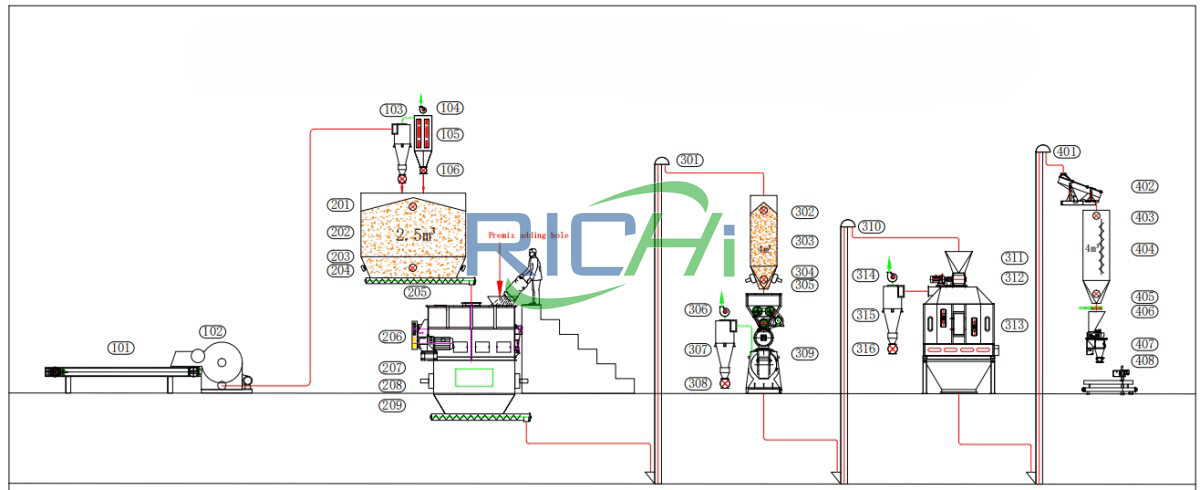

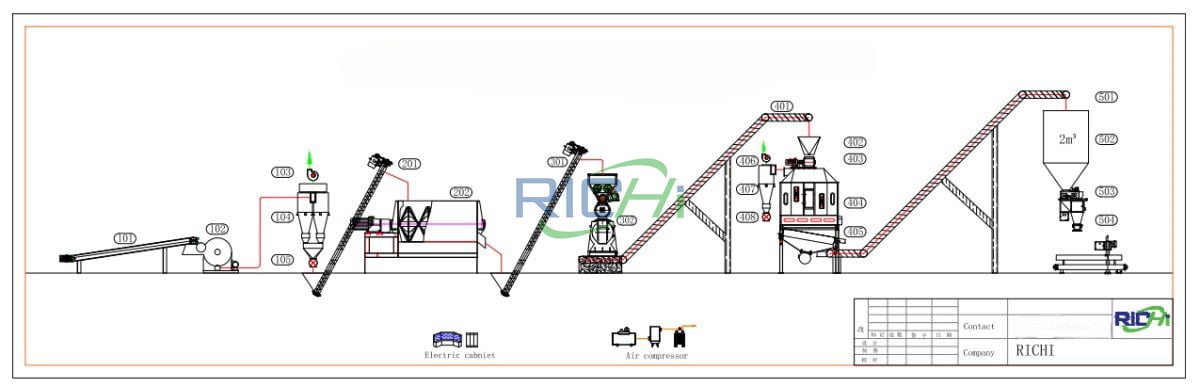

Complete forage pelleting technology usually includes drying, crushing, mixing, pelleting, cooling, and packaging. After the forage is processed through the complete forage pelleting technology, high-quality forage feed pellets can be obtained.

If your raw material is fresh forage waiting to be harvested, bales of forage or hay, etc., then the processing technology of forage pellets will be adjusted according to the moisture and state of the raw materials.

Commercial feed production needs to take into account the humidity and state of raw materials, the area and height of the plant, the customer's budget, and other aspects. Therefore, the design of customized feed production solutions can meet the production needs of different customers, improve feed production efficiency, and reduce feed production costs.

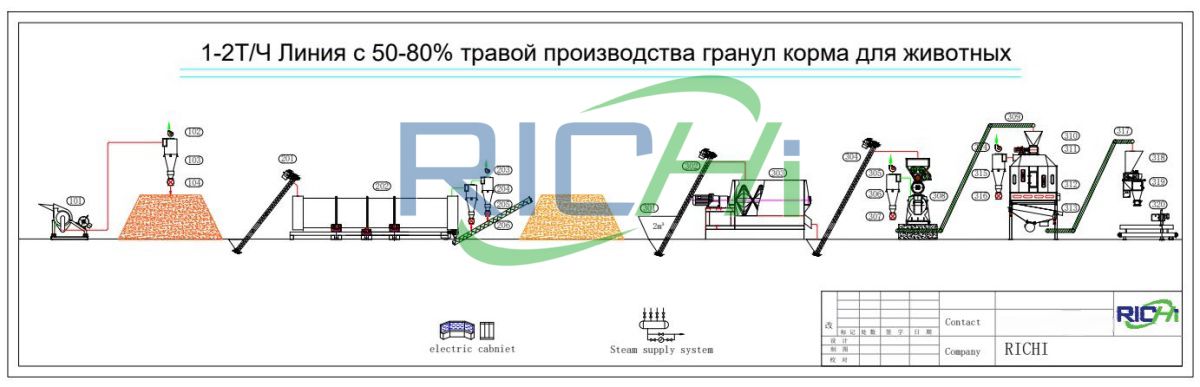

Below, we will list several typical grass pellet production line design solutions for you. These processes are all customized according to customer needs and are applied to our projects in the United States, Australia, Argentina, Russia, and Tunisia.

RICHI can provide a full set of feed production equipment required for forage feed production.

Grass pellet machine is only the direct equipment for processing pellets, but in the actual grass pellet production, it is also necessary to configure forage drying drum, forage crusher, grain crusher, forage mixer, pellet cooler, feed screening equipment, feed packaging equipment, etc.

Of course, these equipment are not needed by all customers. According to the customer's raw material and process requirements, we will configure the most suitable grass pellet processing equipment combination for customers.

Including : anti-arching feeder, conditioner, force feeder, pelletizer, control cabient.

*- including weighing system , hammer mill, mixer .....

*- Same capacity , different designs will lead different prices.

We have been in the pellets manufacturing industry for more than two decades. We have higher technology and rich experience in making grass pellets for feed. If you produce grass pellets feed for sale, it can help you to make profits at a short term.

According to the type of grass, the grass pellet machine can be divided into Alfalfa Pellet Making Machine, Hay Pellet Machine, Elephant Grass Pellet Mill, Timothy Pellet Machine, etc. If you produce grass pellets feed for self-use, it will help you to prepare enough food for the animals. We are definitely the best grass pellet mill manufacturer and supplier for you.

RICHI grass pellet mill is easy to operate and long-term service life. For detail price list and grass pellet mill machine parameters, please fill the following hart to contact with Richi Machinery, we will reply on you as soon as possible!

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.