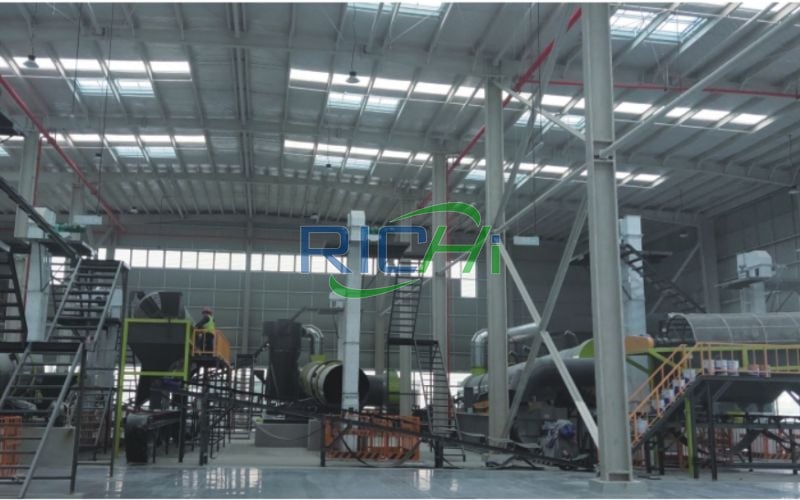

This is a compound fertilizer production line in Austria project with an output of 2 tons per hour. The customer processes a relatively special compound fertilizer: water-soluble fertilizer.

This is a compound fertilizer production line in Austria project with an output of 2 tons per hour. The customer processes a relatively special compound fertilizer: water-soluble fertilizer.

Based on a full analysis of the market capacity and market development prospects, and combined with the technical and economic conditions of the process and the supply conditions of raw materials, the project customer, a biotechnology company, used idle factory buildings and invested 260,000 US dollars to build an annual output of 5,000 tons of water-soluble fertilizer project.

This project uses the built factory buildings and does not require construction. It can be put into production after simple equipment installation and commissioning.

The main business scope of the customer company includes biotechnology promotion services; research and development, production and sales of water-soluble fertilizers, microbial fertilizers, and organic fertilizers; planting and sales of grains, fruits, vegetables, and flowers.

The compound organic fertilizer production project covers an area of 3,528 square meters and was put into production in November 2024. It operates 300 days a year, one shift, 8 hours a shift, and 5 employees.

Name:

Compound Fertilizer Factory

Country:

Austria

Date:

2024.08.22

Capacity:

2T/H

Product Type:

Compound Fertilizer

The install period:

30 Days

Control Mode:

Semi-automatic

Guiding Price:

260,000 USD

Water Soluble Fertilizer (WSF) is a multi-component fertilizer that can be completely dissolved in water. Compared with traditional superphosphate, granulated compound fertilizer and other varieties, water-soluble fertilizer has obvious advantages. It is a fast-acting fertilizer with good water solubility and no residue.

It can be completely dissolved in water and can be directly absorbed and utilized by the roots and leaves of crops. The use of water and fertilizer at the same time, with water and fertilizer, has achieved water and fertilizer integration.

Its effective absorption rate is more than double that of ordinary chemical fertilizers, reaching 80%-90%; and the fertilizer effect is fast, which can meet the nutritional needs of high-yield crops during the rapid growth period.

The water requirement of the drip irrigation system is only 30% of that of ordinary chemical fertilizers, and the fertilization operation can be almost labor-free, which greatly saves labor costs.

This compound fertilizer production line in Austria project uses the built plant with a total area of 3528m2 and an annual output of 5,000 tons of water-soluble fertilizers. The main construction content is shown in the table below.

| Engineering Name | Engineering Content | |

| Main Engineering | 1# Production Workshop | Occupies an area of about 450m2, and is equipped with equipment such as mixing tanks, filling machines, and automatic capping machines. |

| 2# Production Workshop | Occupies an area of about 300m2, and is equipped with equipment such as mixing tanks, filling machines, and semi-automatic capping machines. | |

| Auxiliary Engineering | Office Building | Occupies an area of about 400m2, and is mainly used for office use. |

| Storage and Transportation Engineering | Raw Material Warehouse | Occupies an area of about 80m2. It is used to store various raw materials in production. |

| Finished product warehouse | Occupies an area of about 40m2. It is used to store finished water-soluble fertilizers. | |

| Public Engineering | Water supply | Supplied by the municipal tap water network, with a water consumption of 4492.17t/a |

| Power supply | Power consumption is 50,000 kWh/a, supplied by the municipal power grid | |

| Environmental Protection Engineering | Wastewater | There is no production wastewater in this project. After domestic sewage is discharged into the septic tank for treatment, it is regularly removed and used for agricultural fertilizer |

| Waste gas | The particulate matter generated in the feeding process and the odorous gas generated in the feeding and mixing processes are discharged without organization. | |

| Noise | Equipment is installed in a soundproof workshop, with foundation shock absorption and distance attenuation | |

| Solid waste | Unqualified products are recycled for product blending; waste packaging is collected and sold to waste stations; domestic garbage is collected and regularly removed by the sanitation department | |

Water-soluble fertilizer refers to compound fertilizers containing nitrogen, phosphorus, potassium, calcium, magnesium, trace elements, amino acids, humic acid, alginic acid, etc. that can be completely dissolved in water. There are two types of water-soluble fertilizers in terms of form: solid water-soluble fertilizers and liquid water-soluble fertilizers.

In terms of nutrient content, there are water-soluble fertilizers containing large amounts of elements, water-soluble fertilizers containing medium amounts of elements, water-soluble fertilizers containing trace elements, water-soluble fertilizers containing amino acids, water-soluble fertilizers containing humic acid, organic water-soluble fertilizers, etc.

The products of this compound fertilizer production line in Austria project are water-soluble fertilizers, mainly including water-soluble fertilizers containing trace elements (liquids), water-soluble fertilizers containing medium amounts of elements (liquids), and water-soluble fertilizers containing large amounts of elements (liquids). The total output is 5,000t/a. The product plan is shown in the table below.

| Product Name | Specifications | Annual Output |

| Water-soluble Trace Elements Fertilizer | 1000g | 2500t |

| Water-soluble Medium Elements Fertilizer | 500g | 2300t |

| Water-soluble Trace Elements Fertilizer | 250g | 200t |

The quality of water-soluble fertilizer products should meet the following industry standard indicators, as follows:

| Product Type | Item | Indicator |

| Middle element water-soluble fertilizer liquid product | Middle element content, g/L | ≧ 100 |

| Water-insoluble matter content, g/L | ≦50 | |

| PH (1:250 times dilution) | 3.0-9.0 |

| Product Type | Item | Indicator |

| Trace element water-soluble fertilizer liquid product | Trace element content, g/L | ≧100 |

| Water-insoluble matter content, g/L | ≦50 | |

| PH (1:250 times dilution) | 3.0-10.0 |

The main equipment used in this compound fertilizer production line in Austria project is shown in the table below.

| Number | Equipment name | QTY |

| 1 | Reactor | 2 |

| 2 | Sealing machine | 1 |

| 3 | Labeling machine | 1 |

| 4 | Semi-automatic labeling machine | 1 |

| 5 | Canning machine | 1 |

| 6 | Semi-automatic filling machine | 2 |

| 7 | Automatic twist capping | 1 |

| 8 | Semi-automatic capping machine | 1 |

| 9 | Automatic coding machine | 1 |

| 10 | Carton sealing machine | 1 |

| 11 | Mixing tank | 2 |

| 12 | Feeding machine | 1 |

| 13 | Weighing filling machine | 1 |

| 14 | Capping machine | 1 |

The consumption of main raw materials for this compound fertilizer production line in Austria project is shown in the table below.

| Number | Name | Annual consumption | Remarks |

| Main raw and auxiliary materials | |||

| 1 | Anhydrous copper sulfate | 37.613t/a | Purchased externally, 25kg/barrel |

| 2 | Zinc sulfate | 37.613t/a | Purchased externally, 25kg/barrel |

| 3 | Ammonium molybdate | 30.09t/a | Purchased externally, 25kg/barrel |

| 4 | Ferrous sulfate | 37.613t/a | Purchased externally, 25kg/barrel |

| 5 | Manganese sulfate | 37.613t/a | Purchased externally, 25kg/barrel |

| 6 | Borax | 37.613t/a | Purchased externally, 25kg/barrel |

| 7 | Amino acid calcium liquid 20% | 334t/a | Purchased externally, 150kg/barrel |

| 8 | Magnesium sulfate | 25.075t/a | Purchased externally, 25kg/barrel |

| Energy consumption | |||

| 9 | Electricity | 50,000 kWh | Supplied by the municipal power grid |

| 10 | Water | 4492.17m3/a | Supplied by the municipal tap water network |

This compound fertilizer production line in Austria project will build a new water-soluble fertilizer production line with an annual output of 5,000 tons. The main products include medium-element water-soluble fertilizer (liquid) and trace element water-soluble fertilizer (liquid) sharing two production lines. The process flow is as follows:

The liquid water-soluble fertilizers in this project include medium-element water-soluble fertilizers (liquid) and trace element water-soluble fertilizers (liquid).

The two types of liquid water-soluble fertilizers only differ in raw materials. The production process is exactly the same. The production equipment is dedicated to the tank and the equipment is cleaned regularly.

The plant area of the compound fertilizer production line in Austria project is rectangular, with the 2# production workshop on the north side and the 1# production workshop in the middle. The office building is located on the south side of the plant area, and the raw material warehouse and finished product warehouse are located in the production workshop.

From the plan layout, it can be seen that the production area is relatively concentrated and compact, basically arranged according to the process flow, meeting the production operation requirements and workshop use functions.

The power supply of the compound fertilizer production line in Austria project is provided by the municipal power grid, mainly for production equipment, office lighting, etc., with a power consumption of 50,000 kWh/a.

The water used in the production process of liquid water-soluble fertilizers in this project is tap water. There is no pure water preparation facility in the factory. According to the proportion of raw and auxiliary materials, the water consumption of liquid water-soluble fertilizers in this project is 4422.77m3/a.

In order to ensure the quality of the product, the mixing tank and other production equipment need to be cleaned regularly. The use of tap water will generate a small amount of equipment cleaning wastewater.

This organic fertilizer production line project has 2 mixing tanks for the production of liquid water-soluble fertilizers. The tanks are used for special purposes. The mixing tanks are cleaned regularly every 3 days. The cleaning water consumption is 0.2m3/time, so the cleaning water consumption of the mixing tank is 20m3/a.

The production workshop of this compound fertilizer production line in Austria project is manually cleaned once a week, mainly by mopping the floor manually. The water consumption during the cleaning process is 0.5t/time, so the cleaning water consumption is 21.4t/a.

The water used in this project is supplied by the municipal tap water network. This project mainly includes domestic water. This project has 5 employees, and the daily water consumption of each person is 30L. The domestic water consumption of the whole plant is 0.15m3/d, and the annual working days are 300 days, and the domestic water consumption is 45m3/a.

The amount of domestic sewage generated is calculated as 80% of the water consumption, which is 36m3/a. After entering the septic tank for treatment, it is regularly removed.

The wastewater generated by the cleaning of the mixing tank is reused for the proportioning of liquid water-soluble fertilizers and is not discharged; the water used for the proportioning of water-soluble fertilizers is all used in the product.

The composition of the workshop cleaning wastewater is simple, containing a small amount of fertilizer raw materials spilled in the workshop, which is reused for greening in the factory after simple sedimentation and is not discharged. This compound fertilizer production line in Austria project does not generate production wastewater.

Austria is located in southern Central Europe, with a land area of 84,000 square kilometers, of which 48% is forest and 28% is hilly grassland, and a total population of 8 million.

Austria is rich in forest resources and arable land resources, with a small population and a large amount of land, fertile land, mild climate, and even and sufficient rainfall. It has unique development conditions, making the local agriculture and animal husbandry relatively developed.

In Austria, organic agricultural products have a good reputation. Suppliers of organic agricultural products must hold the EU organic agricultural product certification to ensure that neither chemical fertilizers nor chemical agents are used in the production process.

Water used to produce organic agricultural products must also be regularly tested, and the organic ecological production model must be maintained while complying with strict hygiene standards and product packaging standards.

Therefore, the prospects for processing organic fertilizers in Austria are very optimistic. Austria has a long history and a solid foundation in organic agriculture, and the government has given strong support to the development of organic agriculture, which provides a good external environment for the organic fertilizer processing industry.

The Austrian government supports the development of organic agriculture through multi-faceted and efficient funding to further consolidate its demonstration role in sustainable development.

Government policies include guaranteeing the interests of farmers who grow organic agricultural products, professional processing companies, intermediaries, organic agricultural product management agencies and consumers, and reducing the entrepreneurial costs of entrepreneurs through tax incentives, financial subsidies and other measures to enhance the profitability of organic fertilizer processing plants.

Although the market competition in the organic fertilizer processing industry is becoming increasingly fierce, the continued growth of the global organic fertilizer market provides a broad space for development for this industry. According to statistics, the global organic fertilizer market is expected to continue to grow in the next few years.

Due to the increasing environmental awareness of farmers and the government's supportive policies for sustainable agricultural development, the market demand for organic fertilizers will become increasingly strong.

If you are interested in building compound fertilizer production line in Austria, feel free to contact RICHI MACHINERY to obtain project construction plans: civil engineering design, steel frame design, plant layout, equipment layout, equipment configuration, process design and other information.

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.