This is where you find all our press releases and news articles.

The cost of a cat litter pellet plant is generally between 20,000 and 1.5 million US dollars, and the output covers 1-50t/h.

We can customize various tofu cat litter pellet plants, paper cat litter pellet plants, wood cat litter pellet plants, bentonite cat litter pellet plants, attapulgite cat litter pellet plants, zeolite cat litter lines, diatomaceous earth cat litter pelleting lines, cassava cat litter lines, etc. according to customers' raw materials. Below is the cost of cat litter line equipment for different outputs.

| Production Scale | Investment Cost (USD) |

| 0.3-1T/H | 20,000-120,000 |

| 1-2T/H | 30,000-150,000 |

| 3-4T/H | 50,000-300,000 |

| 5-7T/H | 70,000-500,000 |

| 8-10T/H | 150,000-900,000 |

| 12-20T/H | 250,000-1,000,000 |

| 25-40T/H | 45,0000-1,200,000 |

| 50-60T/H | 900,000-1,500,000 |

For a long time, customized cat litter production plants have become the key to the transformation and upgrading of many companies due to their "tailor-made" characteristics, high flexibility and exclusivity. But they are often mistaken for being expensive and unaffordable.

But in fact, with the continuous advancement of technology and the intensification of market competition, the cost of customized production lines has dropped significantly and tended to be rationalized.

Today, RICHI Machinery will analyze the cost composition of customized cat litter pellet plants for you to learn more about.

Specifically, the cost of customizing a cat litter pellet plant mainly includes the following aspects:

This is the primary investment in a customized cat litter production line, including preliminary demand research, scheme design, drawing, etc. Through a professional design team, it can be ensured that the production line not only meets customer needs, but also has the characteristics of high efficiency and stability.

Of course, most manufacturers now provide free production line design, scheme planning, and equipment configuration services, and RICHI Machinery is one of them. Please remember that it is free. At present, only finding a special design institute to customize the production line is paid.

According to the cat litter pellet plant design plan, cat litter processors need to purchase corresponding production equipment and install and debug it. Thanks to the optimization of the supply chain and the scale effect, the cost of equipment procurement is no longer a difficult threshold to cross.

At the same time, a professional installation team can ensure that the equipment is put into operation quickly and accurately. Equipment cost is the main cost of production line investment.

Modern customized cat litter pellet plants are inseparable from advanced software and control systems. These systems can realize the automation and intelligent management of the production process, improve production efficiency and product quality. With the popularization of technology and the reduction of costs, this part of the investment has become more reasonable.

Transportation price is also an important part of the investment in customized production lines. Since production line equipment is usually large and heavy, the transportation cost is relatively high. The specific transportation price is affected by many factors.

In addition to the above costs, there are also land costs, plant construction, water, electricity, steam and other energy consumption, personnel costs, raw material costs, etc. Depending on the customer's situation, these investment costs will vary greatly.

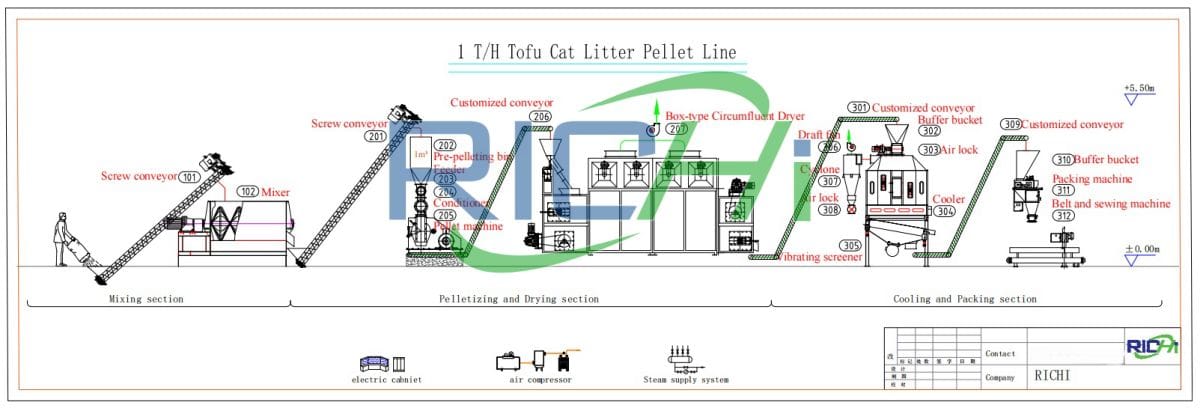

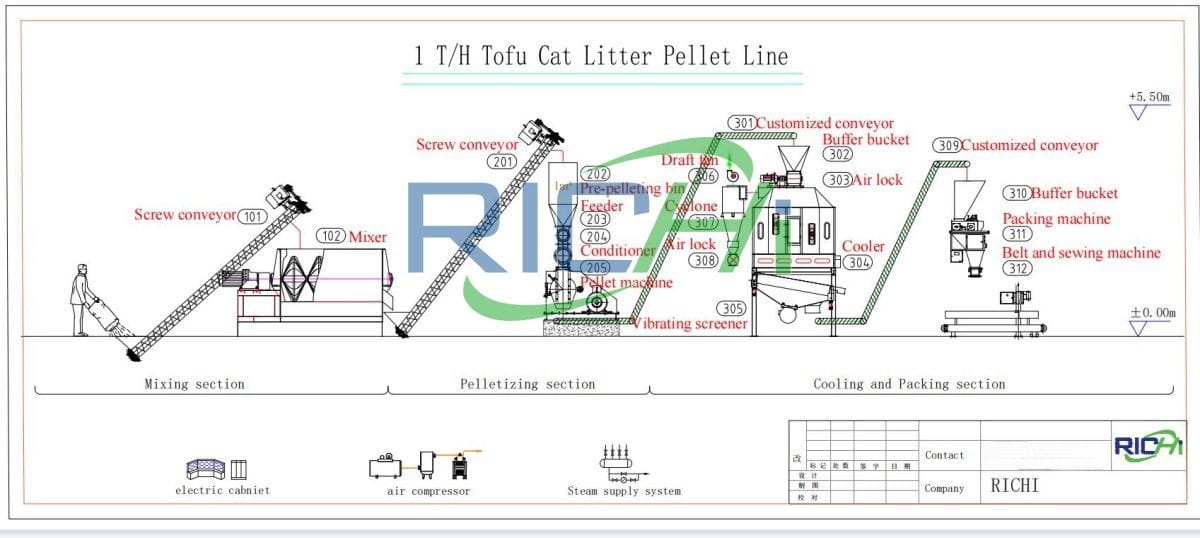

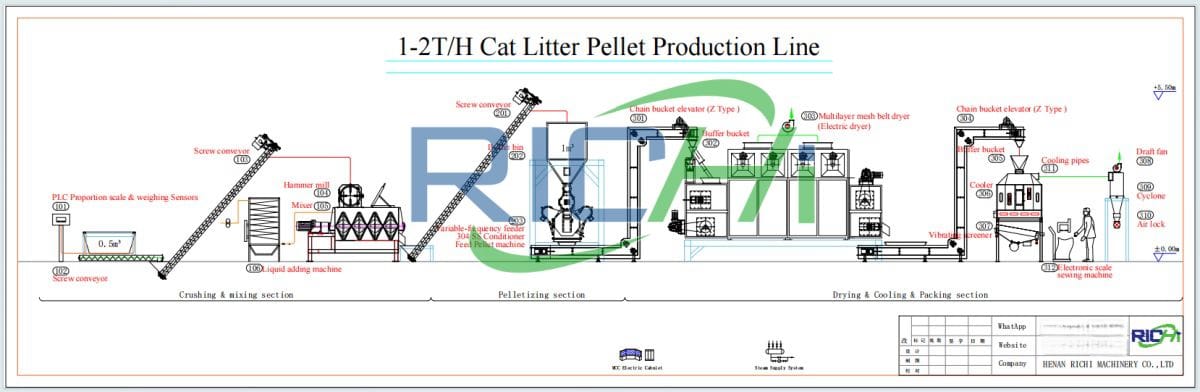

Different cat litter types, different production scales, different process designs, different equipment configurations, and different degrees of automation will affect the final price of the cat litter production line. The following are two of our projects, both with an output of 1-2t/h.

Cat litter pellet plant cost: 59,530 USD

Cat litter pellet line price: 42880 USD

Cat litter pellet plant price: 70940 USD

From the above, it can be seen that even if the processing scale of cat litter is the same at 1-2t/h, if the process is different, the equipment will be different and the price of the pelletizing plant will be different.

In the process of equipment selection, the price of production line equipment will also vary due to the raw material status, degree of automation, and degree of equipment advancement.

For example:

The equipment configuration for the cat litter pellet plant is very complicated. You need to determine the processing technology and equipment of cat litter based on various factors such as your raw material type, raw material moisture, raw material particle size, and the type of cat litter to be processed.

However, as a cat litter equipment manufacturer, here we only give a relatively accurate price for cat litter processing equipment. As for raw materials, civil engineering costs, energy costs, and personnel costs, since they vary greatly from country to country, we will not explain them in detail here.

However, you need to calculate the energy input cost based on the energy consumption of the equipment, which the RICHI engineering team can certainly provide.

The full set of cat litter pellet plants is only to achieve continuous and automated production of cat litter processing. With the increase in the number of pets, especially the popularity of cats, cat litter is a necessity for pet care, and its market demand is increasing year by year. The cat litter processing industry has very good prospects.

With the advancement of technology and the maturity of the market, we believe that the cost of customized production lines will be more transparent and reasonable in the future, creating greater value for cat litter processors. If you are interested in starting a cat litter processing business, feel free to contact RICHI MACHINERY!

Having the right mix of reliable, high-quality pellet machine and pelletizing systems and expert support is essential to your success. Watch how our end-to-end feed pellet plant solutions have helped our customers optimize their performance.

Our customized and future-proofed turnkey pellet plant solutions is designed with you at the core. From vision to reality and beyond, our team stays connected with yours. Giving you peace-of-mind with an expert at your side.

At RICHI, we go beyond project completion. With RICHI Servicee, we’re your dedicated partners in success. Count on us for expert guidance, minimal downtime, and optimized productivity. Choose RICHI for unmatched service and support.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Increase plant productivity, profitability, and safety by integrating high quality equipment into your pellet production line. Over the years, RICHI has become China's top pellet equipment manufacturer. At the same time, RICHI has established valuable partnerships with the world's leading component and raw material manufacturers to bring you the best there is in technology, automation, and efficiency in pelleting plant machinery.

For nearly 30 years, RICHI has been providing best-in-class pellet plant equipment and services to clients across a variety of industries, sizes, and needs. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI Machinery to take your operation to the next level of innovation, quality, and success.

Need help with your pellet manufacturing plant project? Contact us today.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

RICHI Machinery continues to deliver world class pellet mill equipment, pellet plant engineering and project solutions that add value to our customers in the animal feed, wood waste, agriculture waste, organic fertilizer, cat litter and special pellet products industries. Throughout the years, we RICHI Machinery have built strong brand, becoming industry-leading pellet machine manufacturer. We value integrity, promise quality, and prioritize your success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

○ RICHI MACHINERY

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2026 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.