Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Animal feed pellet machine is a mechanical equipment that processes bulk feed raw materials into pellet feed, using raw materials like corn, soybean meal, straw, grass, rice husk, alfalfa, wheat stalk, ect. It is widely used in poultry feed mills, livestock feed mills, aquatic feed mills and breeding industries to provide nutritious feed for various animals and promote their growth and development. The working principle of the animal feed pellet machine is to crush, mix and granulate the raw materials to finally form pellet feed. This kind of granular feed is not only convenient for storage and transportation, but also can effectively prevent the loss and oxidation of feed nutrients.

There are many types of feed pellet machines, suitable for different sizes and types of feed mills. According to different applicable scenarios, animal feed pellet mills are mainly divided into the following:

suitable for processing poultry feed pellets such as chickens, ducks, geese, etc. The pellet diameter is generally 1-4mm.

It is mainly suitable for processing pellet feed for broiler and hen. The size of the pellets is generally 1-4mm.

Mainly suitable for processing ruminant cattle pellet feed (can contain grass or straw), pellet diameter is 4-8mm.

Mainly suitable for processing various pig feed pellets such as piglets, sows, fattening pigs, etc. The pellet diameter is 2-10mm.

Mainly suitable for processing sinking fish pellet feed, using a double-layer or three-layer conditioner, with a pellet diameter of 0.5-4mm.

Mainly used to process special feed pellets such as shrimp and crab. It adopts a three-layer conditioner and the pellet diameter is 0.5-3mm.

suitable for processing grass pellets, alfalfa pellets, timothy pellets and other horse feeds, with pellets size of 5-10 mm.

suitable for processing rabbit pellet feed with different growth cycles, with a pellet diameter of 2-8mm.

In addition to the above, we can also provide camel feed pellet machine, deer feed pellet machine, livestock feed pellet machine, pigeon feed pellet machine, bird feed pellet machine and other equipment.

When choosing animal feed pellet machine, factors such as output requirements, raw material types, and power consumption need to be considered. At the same time, regular brands and reputable manufacturers should be selected to ensure the quality of the machine and the reliability of after-sales service.

Animal feed pellet mill machines are widely used in the feed industry and are suitable for feed mills and farms of various sizes to process various feed raw materials into pellets. This processing method can increase the nutritional content of the feed, improve the taste and digestibility of the feed, and also facilitate storage and transportation.

The pellet feed is usually a compound feed, which is based on the requirements of various varieties, growth age, production performance and other aspects, and in accordance with nutritional standards and feed formulas. Various feed ingredients are ground into powder, mixed thoroughly, and then compressed into pelleted feed by animal feed pellet making machine.

Advantages of pellets made by animal feed pellet machine:

The quality of feed products determines the level of breeding, and feed processing methods are one of the necessary prerequisites to ensure the quality of feed products. Animal feed pellet mill is an important equipment in feed processing.

With the development and progress of the feed and breeding industries, feed processors have higher and higher requirements for feed pelleting. As a result, new high-capacity animal feed pellet presss suitable for the production of high-quality pellet feeds in animal feed factories of all sizes have emerged.

Pressing powdered materials into pellet feed is based on the existence of voids in the powdered materials. The powdery material is a loose body of dispersed powder particles with a certain fluidity.

Under the action of squeezing force, the powder particles with a certain temperature and humidity are close to each other and rearranged, the air contained in the powder particles is gradually discharged, the gap between each other is reduced, the bonding force increases, and the powder itself has potential natural binding substances produce binding effect, and finally the powder is pressed into pellet feed with a certain density and strength.

During the animal feed pellet machine pelleting process, the protein and sugar in the feed become pellets when heated, and the starch is partially gelatinized. The animal feed pellet machine adopts compression pelleting which uses roller and dies to compress the powder into pellet shape.

| model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1~2 | 3~4 | 5~7 | 8~12 | 10~18 | 15~25 | 20~30 | 25~40 | 28~45 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~12 | ||||||||

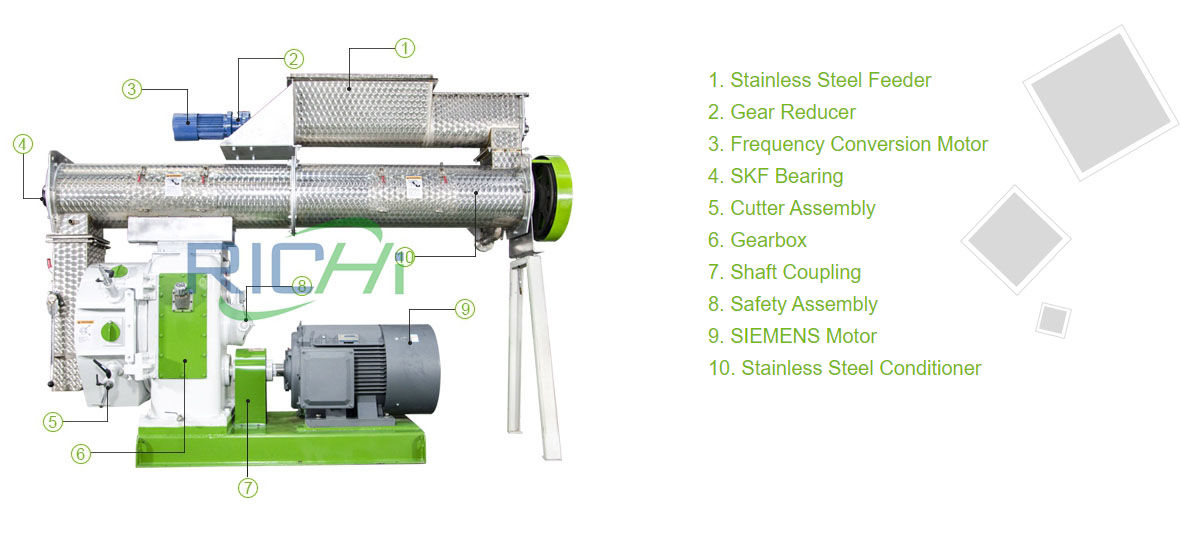

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor |

||||||||

Feed Pellet Making Machine Price: FOB 7,000-100,000 USD

What's animal feed pellet machine price? Because different customers have different requirements for pellets, there will be many differences in the details of our feed pellet machine design. Therefore, the actual animal feed pelleting machine price for different projects are different.

Even if the customer wants to produce the same type of pellets, if the customer';s feed formula, raw materials, and production technology are different, the animal feed pelletizer machine ring die, conditioner, etc. will be different.

The main factors that affect the price of feed pellet mill are the following 4 factors:

01

The problem of scale effect

The cost of parts and components is an important component of the production cost of animal feed pellet mills, which mainly includes raw material procurement fees and raw material processing fees.

Companies with large-scale production usually have strong bargaining power in cooperation with upstream suppliers and can significantly reduce raw material procurement fees and raw material processing fees, thus improving the cost advantage of their products.

In addition, the operating activities of companies with large-scale production are relatively stable, which can ensure continuous research and development and technological innovation, and continue to maintain the technical advantages of animal pellet making machines.

02

Brand issues

Brand is a comprehensive reflection of the company's sales, product quality, maintenance technology, management services and market network and other factors.

Operation and use require continuous technical training, and animal feed pellet machines of different brands have certain differences in operation, maintenance, etc., which makes the replacement of animal feed pellet mill brands have a certain replacement cost, and customers are sticky to the brand. If it is high, old customers will not easily purchase products from newly entered companies.

03

Technical issues

The animal feed pellet mill industry is a multi-disciplinary industry integrating mechanical design and processing, and feed technology research, with obvious technical problems.

Especially in recent years, the industry has continuously absorbed new achievements in science and technology, the technological level has developed rapidly, and the technology-intensive characteristics have become more significant. At present, many key technologies in the industry have been mastered by major domestic and foreign companies, and many of them have established technical issues in the form of patents.

04

Talent issues

Only after long-term training can the company have a group of skilled production personnel and qualified technical personnel.

High-end industrial talents with high technical R&D capabilities and process technology levels as well as skilled maintenance personnel are the key to effective product quality control and effective after-sales service implementation. There is a certain talent problem in the industry.

When choosing an animal feed pellet machine, there are several factors to consider to ensure you choose the right equipment for your needs. Here are some suggestions:

To sum up, when choosing an animal feed pellet machine, you need to comprehensively consider factors such as production needs, raw material type, equipment quality, energy consumption and efficiency, brand and service, and price to ensure that you choose the equipment that best suits your needs.

The production process of a feed pellet production line generally includes the following processes: raw material reception and storage, cleaning (removal of impurities), crushing, batching, mixing, granulation, cooling, granulation, grading, finished product packaging, storage and distribution.

01

Raw material cleaning

02

Ingredients process

03

Crushing process

04

Mixing process

05

Pelleting process

06

Finished product packaging process

The animal feed pellet production process is carried out in accordance with certain design specifications according to the animal feed production scale, raw material varieties, and product types. Compared with the powder feed production process, the pellet feed processing technology is based on the raw material receiving and pretreatment, grinding, batching, mixing and other processes, adding a pelleting system.

Animal feed pellet production equipment is the important equipment in the breeding industry and is used to process raw materials into pellet feed. In order to ensure production efficiency and product quality, the animal feed pellet production line needs to be equipped with a series of equipment.

General feed mill pelleting system includes powder conditioner, animal feed pellet milling machine, pellet cooler, animal feed hammer mill, grading screen and packaging machine, etc. The production process of aquatic pellet feed often also includes an extruded part, and the corresponding feed equipment includes powder conditioner, extruder, maturer, dryer, cooler, etc.

The equipment required for the animal feed pellet production line and its functions will be introduced in detail below:

01

Raw material storage and transportation equipment

The first stage of the animal feed pellet production line is raw material storage and transportation. The main equipment at this stage includes:

The role of these equipment is to ensure a stable supply of raw materials and maintain the continuity of the animal feed pellet machine system.

02

Mixing equipment

Mixing equipment is the core part of the animal feed pellet production line. Its main equipment includes:

The role of the mixing equipment is to ensure that the feed formula is accurate and the raw materials are mixed evenly to improve production efficiency and product quality.

03

Granulation equipment

Animal feed pelletizing equipment is equipment that compresses mixed animal feed raw materials into pellets. Its main equipment includes:

The function of the animal feed pelleting machines are to make the mixed feed into granules that meet the requirements to improve the digestion and absorption rate and use effect of animal feed.

04

Finished product storage and transportation equipment

Finished product storage and conveying equipment is the final stage of the animal feed pellet production line. Its main equipment includes:

The role of finished product storage and conveying equipment is to ensure that the finished pellet feed is properly stored and transported to meet market demand.

To sum up, the animal feed pellet production line needs to be equipped with a series of equipment, including raw material storage and conveying equipment, mixing equipment, pelleting equipment and finished product storage and conveying equipment. The configuration and optimization of these equipment is one of the key factors to ensure production efficiency and product quality.

At the same time, in order to meet the changing market demand and the development needs of the breeding industry, animal feed pellet production lines also need to continuously carry out technological upgrades and innovations to improve production efficiency and reduce costs, so as to provide better support and guarantee for the development of the breeding industry.

With the continuous development of the breeding industry, animal feed pellet machines, as an efficient and environmentally friendly feed processing equipment, are increasingly favored by farmers.

However, among the many brands of feed pellet machines on the market, how to choose a brand that suits you has become a difficult problem. This article will provide a detailed analysis of how to choose a feed pellet machine brand from the following aspects.

01

Understand the brand background

Before choosing animal feed pellet machine brand, you must first understand the background of each brand. You can learn about the establishment time, registered capital, production scale, sales performance and other information of each brand by consulting relevant information, consulting industry experts or visiting exhibitions. Generally speaking, big brands with strength and technology accumulation are more guaranteed in terms of product quality and after-sales service.

02

Inspect product quality

Product quality is one of the important indicators for choosing a feed pellet machine brand. When purchasing, you can examine product quality from the following aspects:

03

Consider after-sales service

Good after-sales service is essential for the long-term use and maintenance of the animal feed pellet making machine. When choosing a brand of feed pellet machine, you should understand its after-sales service content, including warranty period, maintenance scope, parts supply, technical support, etc. Choosing a brand with complete after-sales service can avoid production losses caused by equipment failure or maintenance problems.

04

Compare prices

After meeting the above requirements, price comparisons can be made between animal feed pellets machines of different brands and models. Generally speaking, the product quality and service of big brands are more guaranteed, so the prices are relatively higher; while the prices of some small brands or unbranded products may be lower, but the quality and after-sales service may not be guaranteed. Make your choice based on your budget and needs, weighing the pros and cons.

05

Actual trial and on-site inspection

If you have the conditions, you can go to the animal feed pelletizer machine manufacturer for on-site inspection to understand the production technology and process. In addition, you can also actually try out different brands and models of feed pellet machines to experience their performance in operation, performance and noise, so as to make a better choice.

To sum up, choosing animal feed pellet machine brand requires a comprehensive evaluation from multiple aspects. When purchasing, farmers must consider their own actual conditions and pay attention to product quality, after-sales service and price.

Through careful comparison and screening, choose a high-quality feed pellet mill machine brand that suits you to provide strong support for the development of the breeding industry.

Why animal feed pellet machine is so important to pellet quality? There are many factors that affect the quality of pellets, the most important ones are formula, powder size, conditioning, roller and die properties and cooling. Among them, the influence of conditioning on the quality of pellets accounts for about 20%, and the influence of the working characteristics of the press die on the quality of pellets accounts for about 15%.

These two elements are directly determined by the animal feed pellet mill. Even if the formula has the greatest impact on pellet quality, accounting for about 40%, as a feed processing equipment, the feed pelletizer is undoubtedly the most critical. Then, how does the animal feed pellet machine affect the pellets quality? We will explain in detail below:

01

Conditioning of animal feed pellets

Conditioning is a process in which the powder is fully contacted and stirred with a small amount of steam in the conditioner of the granulator. The role of conditioning is:

The conditioning treatment is conducive to the gelatinization of starch, the digestion and absorption rate of feed, the improvement of pellet quality, the increase of output, the reduction of energy consumption, the reduction of the wear of the die and the roller, and the improvement of their service life.

02

The roller and ring die properties of the animal feed pellet machine

The influence of the working characteristics of the die on the quality of the pellets accounts for about 15%. Among them, the length to diameter ratio of the die hole is the main factor, and other factors such as the linear speed of the die, the gap between the die rolls, and the size of the output also have a certain influence. When the length to diameter ratio is large, the material stays in the die hole for a long time, and the pressure is also large, so the hardness of the pellets is low.

Different types of pellet feed have different requirements for the length to diameter ratio. For example, the length to diameter ratio of livestock and poultry feed is generally 8-10, aquatic feed is 14-16, and shrimp feed is 20 or more. The linear speed of the die has been determined during the design of the animal feed pellet granulator and generally cannot be changed at will.

The gap between the pressure die and the pressure roller should be adjusted properly, generally between 0.1-0.2mm. If the gap is too small, there will be friction between the pressure die and the pressure roller, which will accelerate the wear of the pressure die and the pressure roller. However, if the gap is too large, the output will be reduced, and even the particles will not be able to be pressed.

The output size will affect the residence time of the material in the die hole, and the pellet quality will be better when the output is low. So sometimes in order to ensure quality, don't pursue output too much.

03

Formulation

The animal feed formula has the greatest impact on the pellet quality, accounting for about 40%. This is due to the comprehensive physical properties of various feed making raw materials. Some raw materials are easy to make granules, but some are difficult to make granules (mineral salt, sand, etc.). Therefore, everyone must have a clear understanding of the influence of the formula on the quality of the pellets.

Here is a practical example. The pellet quality of a certain feed factory's pellet feed has been poor. The formula technicians believe that their formula nutrition is appropriate, and the poor pellet quality has nothing to do with them.

The technicians in the workshop took some measures, and the quality of the pellets was not ideal. After explaining the truth to them, the formulation technicians made corresponding changes to the formula, and the quality of the pellets was immediately improved.

04

Powder particle size

The influence of powder particle size on animal feed pellet quality is about 20%. If the particle size is too coarse, the quality of the pellets will not be good.

The inclusion of particles in the powder will also affect the quality of the pellets. According to experience, the powder content distribution of general livestock and poultry pellet feed as follows:

The fine material with a small particle size can fill the gaps between the pellets with a larger particle size to improve the quality of the pellets. However, if the pellet diameter required to be produced is smaller, the particle size of the powder is required to be finer.

05

RICHI Feed Mill Definition

The effect of cooling on pellet quality is about 5%. The quality of the cooling effect will have an impact on whether the pellets meet the cooling requirements (reduction and precipitation), and whether there are cracks on the surface.

The raw materials required for animal feed production mainly include cereals, proteins, fats, minerals, etc.

The raw materials required for feed production mainly include cereals, proteins, fats, minerals, etc. These raw materials contain most of the nutrients needed for animal growth and development.

Therefore, selecting appropriate feed ingredients can ensure the healthy development of animals and improve breeding efficiency.

The animal feed pellet machine plays a vital role in livestock and poultry breeding, and its impact on feed processing and feed quality cannot be ignored. The following is a discussion on some aspects of the importance of feed pellet machines in livestock and poultry breeding:

To sum up, the animal feed pellet manufacturing machine is of great significance in livestock and poultry breeding. It can improve feed utilization, improve feed taste, reduce dust and noise, improve feed quality and stability, reduce feed waste and environmental pollution, and facilitate storage and transportation.

Therefore, the reasonable selection and use of animal feed pellet machines in livestock and poultry breeding is of great significance to improving production efficiency and economic benefits.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.