Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

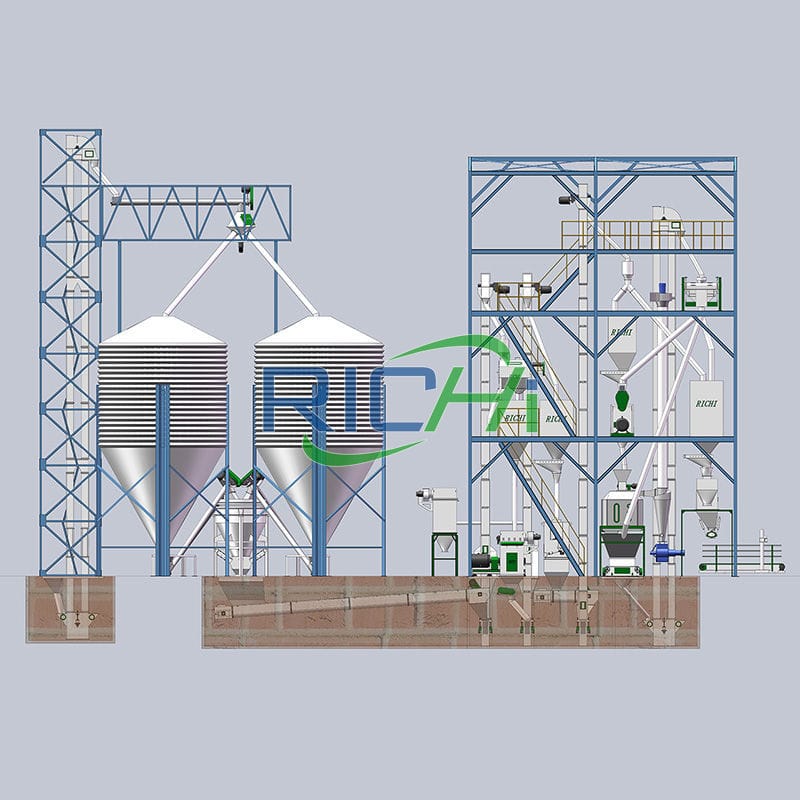

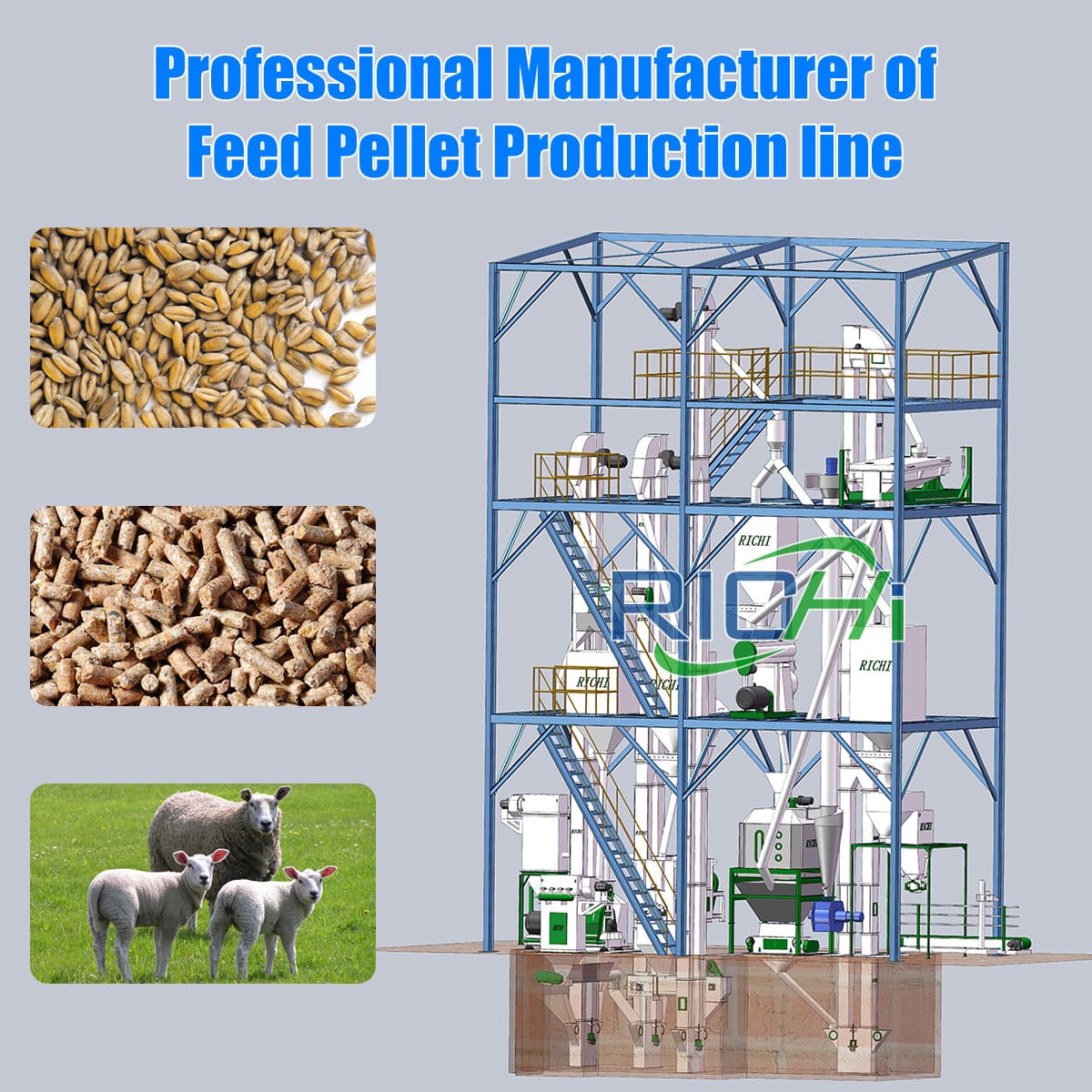

Sheep feed pellet production line is used to process sheep feed pellets based on various raw material formulas. It can be installed in feed mills and farms of various specifications. RICHi offers turn-key project about 1-100TPH complete sheep feed pellet production line, according to the requirement, different output configuration can be customized and provides more value added service to customers. All RICHI animal sheep feed production lines /complete sheep feed manufacturing plants are tailor-made to suit the customer's specific requirement, which also implies a close dialogue with the client regarding present and future requirements as well as local conditions.

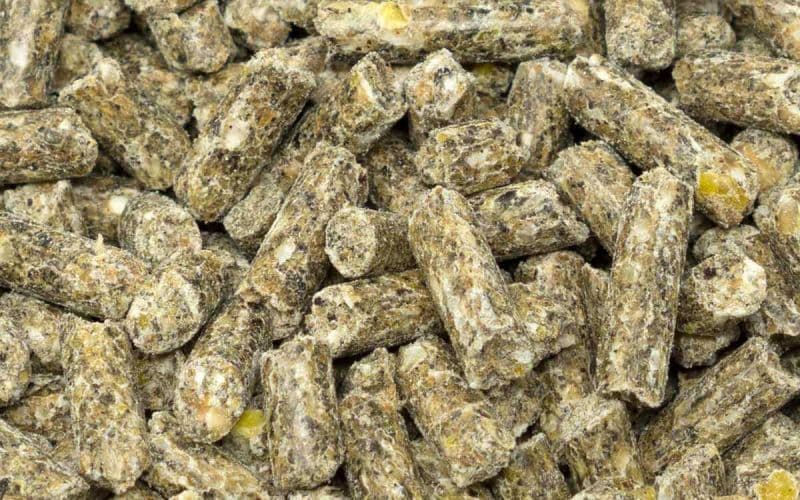

Sheep feed production line is mainly set up in sheep feed mills, ruminant feed mills and sheep farms. This integrated feed processing system is mainly used to process Hay Pellets, Grass Pellets, Fermented Feed, Timothy Pellets, Roughage Pellets, Concentrate Feed Pellet, Alfalfa Pellets, Beet Pulp Pellets for sheep and goat.

Richi Machinery is one of the very few sheep feed mill manufacturers with the ability to design, manufacture and supply each and every key sheep feed processing machine in the sheep feed production line, as well as designing and building the sheep feed processing plant as a whole.

When designing a customer specific sheep feed production line solution, we always take account of the account for:

Wherever your sheep feed pelleting plant is located and whether you produce feed pellets for Sheep, Lake Sheep, Goat, Meat Sheep, Fattening Sheep, etc., we offer a full range of sheep feed production machines and equipment – from raw material intake to finished feed storage.

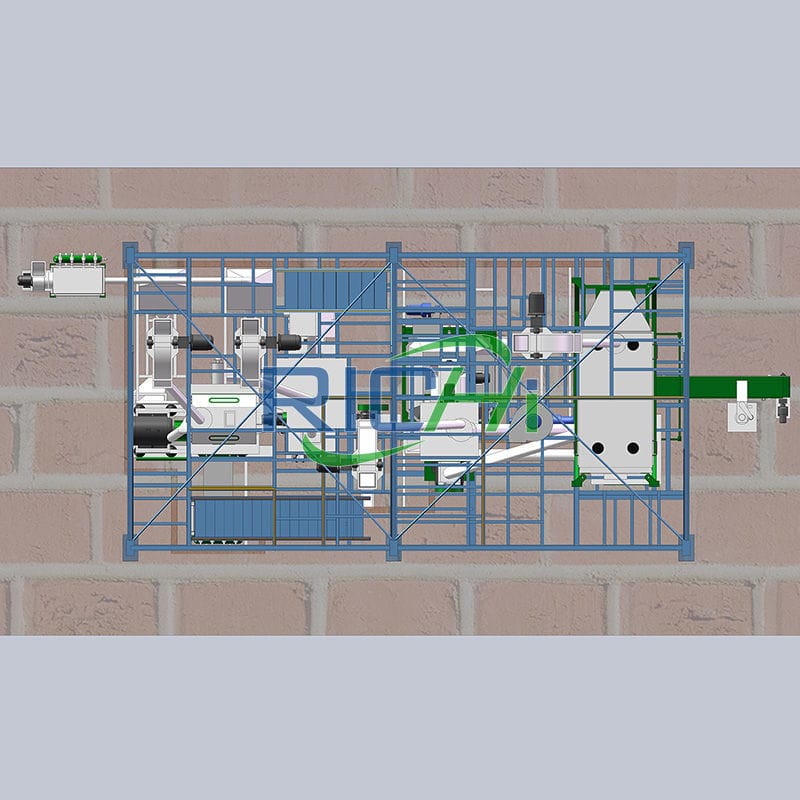

This pellet feed production line is an automated feed processing unit with easy operation, high output and labor saving. It is an ideal choice for feed mills and farms. It can be customized and installed according to the area of the customer's plant. Sheep feed processing equipment has a wide range of applications and strong versatility.

Users can also choose to produce ruminant feed, livestock and poultry feed or fish feed according to their needs. It is suitable for feed mills and farms of various sizes.

Traditional sheep feed production methods usually require large-scale production and cannot be adjusted according to market demand. However, with a customized chicken feed production line, the situation is very different.

These equipment can be designed and manufactured according to your actual needs, whether you need to produce dozens of tons of feed or just a few hundred kilograms, you can meet your needs.

A customized sheep feed production line can not only produce according to your needs, but also improve production efficiency.

This is because these equipment are usually equipped with advanced production technology and equipment, which can realize the automated production process, greatly reducing the need for manual operation, thereby improving production efficiency.

In addition, a complete set of customized sheep feed pellet production line equipment can also improve the quality of the product. This is because these equipment have been carefully designed and manufactured to ensure that the quality of the feed produced meets the highest standards.

And, because these equipment can be adjusted according to your needs, they can adapt to a variety of different production conditions, thus ensuring the quality of the product.

Finally, a complete set of customized sheep feed production line equipment can also help improve environmental performance. This is because these equipment usually adopts environmentally friendly design and materials, which can reduce the impact on the environment during the production process.

And, because these equipment can be adjusted according to your needs, they can adapt to a variety of different production conditions, which further improves environmental performance.

In general, the sheep feed production line provides a flexible, efficient, high-quality and environmentally friendly production method. The customization advantage of the full set of sheep feed production line equipment provides strong support for this model.

The configuration of the sheep feed production line is carefully designed according to the on-site survey or the actual requirements of the customer, which fully reflects the rationality, effectiveness, applicability, large output, low wear and low operating cost of the sheep feed mill design.

According to different technological requirements, various types of sheep feed machinery are combined to meet customers' different sheep feed manufacturing process requirements.

| Scale | Total Power | Site Requirements | Installation Cycle | Sheep Feed Mill Cost(USD) |

|---|---|---|---|---|

| 1-2T/H | 47-75KW | 300-500m² | 7-15 Days | 10000-50000 |

| 3-4T/H | 53-165KW | 300-700m² | 15-20 Days | 5,0000-12,0000 |

| 5-7T/H | 68-259KW | 400-800m² | 20-40Days | 7,0000-25,0000 |

| 8-10T/H | 125-410KW | 800-2000m² | 45-60 Days | 150,000-300,000 |

| 12-20T/H | 358-620KW | 1500-3000m² | 60-90 Days | 250,000-580,000 |

| 25-40T/H | 545-870KW | 2000-4000m² | 90-120Days | 45,0000-850,000 |

| 50-60T/H | 710-1120KW | 3000-5000m² | 100-140 Days | 900,000-1,400,000 |

| 60-80T/H | 815-1370KW | 5000-8000m² | 130-160 Days | 1,450,000-1,800,000 |

| 80-100T/H | 1230-1700KW | 8000-20000m² | 160 -190Days | 2,000,000-2,800,000 |

According to the regulations of the feed industry, sheep feed factory construction projects can be divided according to the size of the production scale.

| Scale(t/h) | ≤2.5 | 5-10 | ≥20 |

|---|---|---|---|

| Factory type | small | medium | large |

Currently, our sheep feed production lines have been exported to the United States, Russia, Argentina, India, Brazil, Germany, France, Saudi Arabia, New Zealand, Uzbekistan and other countries.

According to the needs of different customers, we have provided a complete set of cattle feed machines to customers in more than 100 countries around the world, including pasture cattle feed pellet equipment, alfalfa pellet equipment, hemp cattle feed pellet equipment, cattle feed mixing plant equipment, corn cattle feed plant equipment, cattle silage feed making machine, fermented cattle feed equipment, cattle mash feed plant equipment, etc.

According to customer different sheep feed production types, different output configuration can be customized. We devote ourselves to undertaking all sheep feed production line with 1-100 tons per hour and to providing more value added service to all the customers.

Richi Machinery provides global customers with a one-stop, complete set of professional sheep animal feed production line solutions (business plan for sheep feed production) to solve the problems of customers, especially pure investment customers, such as technical difficulties and poor understanding of sheep feed equipment, so that the needs and positioning of the project are more clear, and at the same time, the customer's equipment selection range is more concentrated, reducing the cost of energy and financial resources.

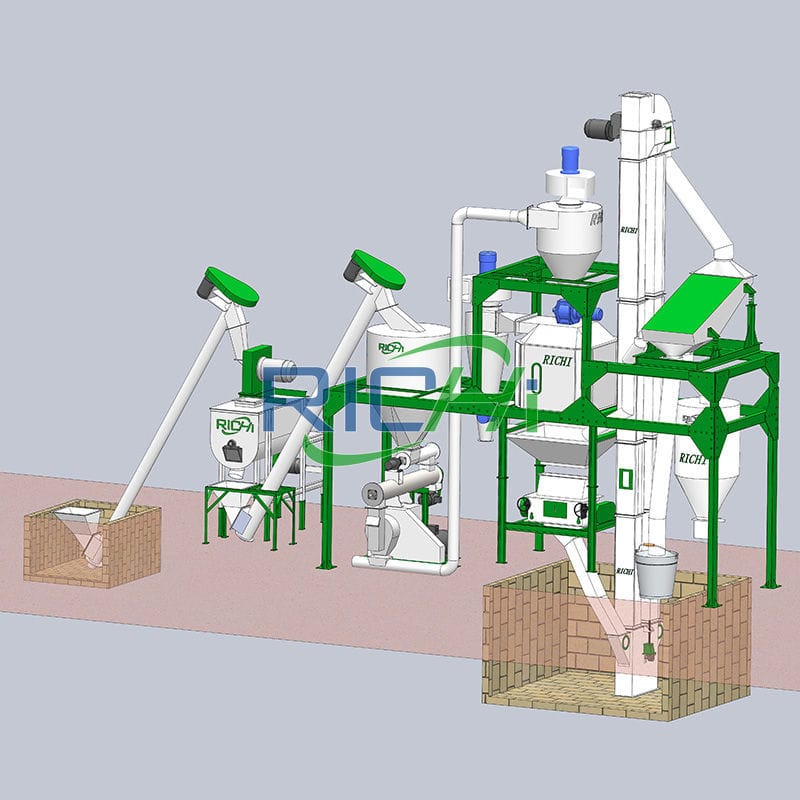

If you want to start a new sheep feed pellet line for your sheep feed mill or sheep farm, you should pay attention to the following main processes:

Due to the influence of various objective factors such as sheep feed raw materials, processes, formulas, project area, local regulations, etc., various technological sheep feed production process and sheep feed equipment configurations have appeared in the actual sheep feed plant design.

Therefore, if you want to build a high-efficiency, high-quality, high-return sheep feed production line, please do not hesitate to contact Richi Machinery and communicate directly with our engineer team, you will definitely get a satisfactory answer. The following is the sheep feed mill machine configuration display of sheep feed production business plan we have done in several customer project :

| Sheep feed making machine name | Model | QTY |

|---|---|---|

| Bale breaker | MPKJ170*225 | 1 |

| sheep grass cutting machine |

TDSJ120*600 |

1 |

| sheep feed grinder | 9FQ50-100 | 1 |

| sheep feed mixer machine |

SLHY.1 |

1 |

| sheep feed pellet machine(with force feeder) | SZLH-M450 | 1 |

| cooling machine | SKLN11x11 | 1 |

| Auxiliary equipment: Belt conveyor*TDSJ100*600, U-Screw conveyor*TLSSU30, Bucket Elevator*TDTG40/23, Cyclone*SK600, Pulse dust collector*TBLMa.36b, Vibrating screener*TDZS80, Automatic Packing machine*DCS-50, etc. | ||

| Complete set sheep feed making machine price: 100000-180000USD | ||

| Sheep feed machine name | Model | QTY |

|---|---|---|

| sheep feed grinder machine | TDSJ120*600 | 2 |

| drum dryer | ф2400*100000*3 Layer | 2 |

| single shaft double ribbon mixer | SLHY5.0L | 2 |

| goat feed pellet making machine(with force feeder) | SZLH508 | 3 |

| cooling Machine | SKLN20*20 | 1 |

| rotary screener | SFJH125*2C | 1 |

| Auxiliary equipment: Belt conveyor*TDSJ120*600, U-Screw conveyor*TLSSU40, Scraper conveyor*TGSU32, Bucket Elevator*TDTG50/28, Cyclone*ф800, Pulse dust collector*TBLMa.36b, Auto Packing machine*DSC-50, etc. | ||

| sheep feed making machine price: 500000-800000USD | ||

| Sheep feed machine name | Model | QTY |

|---|---|---|

| hammer mill for sheep feed | 9FQ56-120 | 1 |

| sheep feed mixture machine |

SLHY2.5L |

1 |

|

sheep feed pellet making machine(with force feeder) |

MZLH520 |

1 |

| cooling machine | SKLN20*20 | 1 |

| vibrating screener | TDZS100 | 1 |

| automatic packing machine | DCS-50 | 1 |

|

MCC Control Center;Mimic control panel |

/ |

1 |

| Auxiliary equipment: Belt conveyor*TDSJ120*600, Screw conveyor*TLSU30,Bucket Elevator*TDTG36/28, Cyclone*SK1000, Pulse dust collector*TBLMa.36b,Oil adding machine *YZTG100a,etc. | ||

| Sheep feed making machine price: 130000-250000USD | ||

| Goat feed making machine name | Model | QTY |

|---|---|---|

| grinder machine for sheep feed | 9F56*40 | 1 |

| sheep food mixer machine | SLHY1.0A | 1 |

| sheep feed pellet making machine(with force feeder) | SZLH250 | 1 |

| cooling machine | SKLN1.0*1.0 | 1 |

| vibrating screener | TDZS80 | 1 |

| packing equipment | DCS-50 | 1 |

| MCC Control Center;Mimic control panel | / | 1 |

| Auxiliary equipment: Winnowing cyclone*SK60, Screw conveyor*TLSS16, Screw conveyor*TLSS20, Storage bin*1m³, Cooling draught fan*4-72-3.6A, Cooling cyclone*SK60, etc. | ||

| Small sheep feed machine price: 30000-70000USD | ||

The major operations involved in the sheep livestock feed production lines are: raw materials preparation, primary crushing, molasses mixing, fine crushing, pellet making and packaging(optional).

In addition to the relevant content in the design task book or design tender, the basis for the process design of the sheep feed production line is also the design standards and specifications promulgated by the country and region; the second is the source of raw materials, product sales, and feed in the region that need to be further collected. And collection of production technology level and other information, design data and experience materials of typical sheep feed factories.

To sum up, the specific basis for process design mainly includes:

The process design methods of sheep feed mills are divided into two types: general design and rapid design. The general design steps are:

The rapid design method is to directly adopt the existing universal design or standard design full set of materials with universal promotion significance. When the actual situation is slightly different, the general design needs to be partially adjusted and modified. The salient features of universal design are convenience, time-saving, and labor-saving. Therefore, it is often adopted by feed mill suppliers with similar conditions.

01

Evaluate product quality

02

Evaluate production capacity

03

Evaluate the service level

Through the above evaluation, we can choose an excellent sheep feed production line equipment manufacturer with high product quality, strong production capacity, and excellent service level, which can provide customers with cost-effective products and services.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.