Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

The cattle feed production line is based on mechanization, electrification and automation technology, combined with the physical and chemical characteristics of cattle feed and feeding needs, and is designed and manufactured to integrate the processes of aggregation, crushing, mixing and packaging. Its ultimate goal is to achieve advantages in stable quality, high production efficiency, cost reduction and improved production environment. Richi Machinery offer 1-100t/h cattle feed manufacturing process solutions and consulting to transform a wide range of feed ingredients to safe, healthy and nutritious cattle feeds.

Cattle feed production line is mainly used in feed mills, cattle farms, etc. of various sizes. With the rapid development of modern breeding industry, especially the continuous improvement of industrial breeding, green and environmental protection has gained wide attention.

The cattle feed production line is a new production model that has emerged with this trend, and has a wide range of application space and development prospects in the cattle feed industry.

The development direction of cattle feed production line in the future will be more intelligent. In addition to being able to automatically complete each link on the production line, it will also combine emerging technologies such as big data, Internet of things and intelligent control systems to monitor production conditions in real time, analyze feedback data, and continuously optimize, while improving production efficiency and product quality, it can better meet the personalized needs of different users.

Richi Machinery deliver full-line cattle feed plant solutions designed for optimized work flow throughout the cattle feed mill, complete overview, high level of biosecurity and excellent cattle feed production conditions.

We design and deliver complete full-line cattle feed plants worldwide. No matter where in the world and no matter which requirements you may have, RICHI has a matching cattle feed production plant solution for calves& youngstock, diary cattle and beef cattle feed manufacturing.

We have experience in designing cattle feed mill solutions in general and suited to the project site and our customer's requirements. We aim to meet cattle health and growth requirements at each stage of their lives.

| Capacity | Country |

|---|---|

| 10-12 T/H Cattle Feed Plant For Hemp Pellets | America |

| 5T/H Cattle Feed Plant For Alfalfa Pellets | Argentina |

| 3-5T/H Cattle Feed Plant | Indonesia |

| 15-16T/H Cattle Feed Plant | Saudi Arabia |

| 10T/H Cattle Feed Plant | South Africa |

| 3-4T/H Cattle Feed Plant | Hong Kong, China |

| 10T/H Cattle Feed Plant For Mash Pellet Feed | Mauritania |

| 0.8-1.2 T/h Cattle Feed Pellet Plant | Uzbekistan |

| 1T/H Cattle Hay Grass Pellet Plant | Uzbekistan |

| 0.8-4T/H Livestock Cattle Feed Mill For Wheat Straw Pellets | South Africa |

| 20T/H Animal Feed Mill | Indonesia |

| 16-20T/H Animal Feed Mill | UAE |

| 20-30 T/H Automatic Dairy Cow Feed Plant | Russia |

| 400,000T/A Animal Feed Production Line | Brazil |

The price of cattle feed production line is affected by many factors such as plant area, automation level, production capacity, workpiece size, process equipment, etc., so it is impossible to give a direct quotation. Users need to provide specific requirements, and we will submit them to the technical department for evaluation based on the requirements, and provide a preliminary plan and quotation.

Choosing a manufacturer with qualifications, R&D team and supporting services can reduce subsequent troubles, and using professional brand accessories can improve durability and product quality.

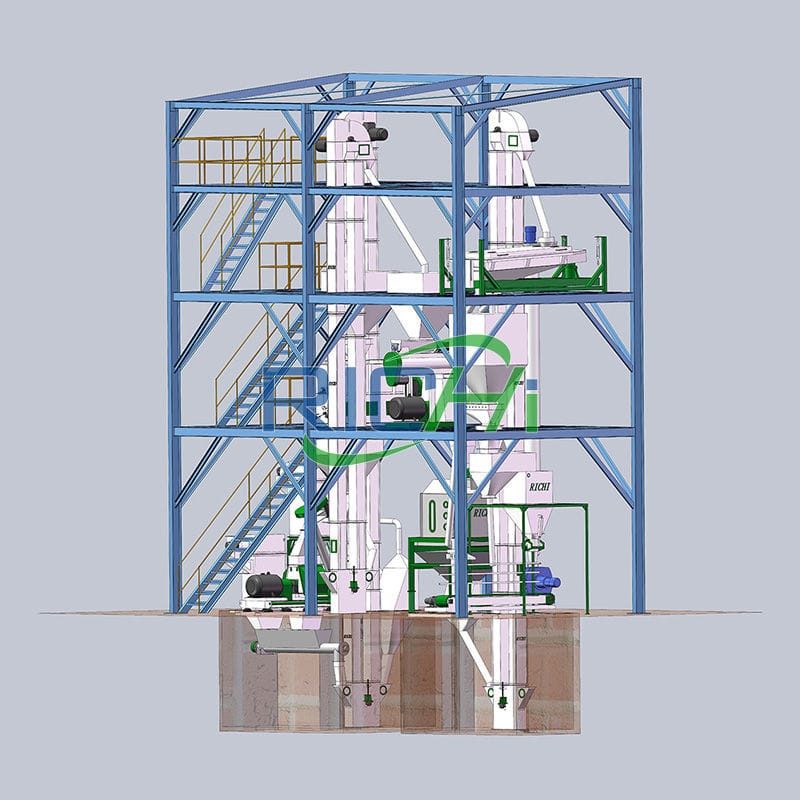

The configuration of the cattle feed manufacturing plant is carefully designed according to the on-site survey or the actual requirements of the customer, which fully reflects the rationality, effectiveness, applicability, large output, low wear and low operating cost of the cattle feed mill design. According to different technological requirements, various types of cattle feed machinery are combined to meet customers' different cattle feed manufacturing process requirements.

| Scale | Total Power | Site Requirements | Installation Cycle | Cattle Feed Mill Cost(USD) |

|---|---|---|---|---|

| 1-2T/H | 47-75KW | 300-500m² | 7-15 Days | 10000-50000 |

| 3-4T/H | 53-165KW | 300-700m² | 15-20 Days | 5,0000-12,0000 |

| 5-7T/H | 68-259KW | 400-800m² | 20-40Days | 7,0000-25,0000 |

| 8-10T/H | 125-410KW | 800-2000m² | 45-60 Days | 150,000-300,000 |

| 12-20T/H | 358-620KW | 1500-3000m² | 60-90 Days | 250,000-580,000 |

| 25-40T/H | 545-870KW | 2000-4000m² | 90-120Days | 45,0000-850,000 |

| 50-60T/H | 710-1120KW | 3000-5000m² | 100-140 Days | 900,000-1,400,000 |

| 60-80T/H | 815-1370KW | 5000-8000m² | 130-160 Days | 1,450,000-1,800,000 |

| 80-100T/H | 1230-1700KW | 8000-20000m² | 160 -190Days | 2,000,000-2,800,000 |

Different configurations, functions, and materials will correspond to different prices, and the same is true for cattle feed production lines. The price of cattle feed production lines is evaluated based on your plant area, automation level, production capacity, cattle feed type (grass feed? Grain feed? Premix?), product size (Pellet? Mash?), equipment required for the process, and other factors. You need to provide demand information and requirements so that we can give an accurate quotation.

According to customer different cattle feed production types, different output configuration can be customized. We devote ourselves to undertaking all cattle feed production line with 1-100 tons per hour and to providing more value added service to all the customers.

Richi Machinery provides global customers with a one-stop, complete set of professional cattle feed processing plant solutions (business plan for cattle feed production) to solve the problems of customers, especially pure investment customers, such as technical difficulties and poor understanding of cattle feed equipment, so that the needs and positioning of the project are more clear, and at the same time, the customer's equipment selection range is more concentrated, reducing the cost of energy and financial resources.

If you want to start a new cattle feed pellet line for your cattle feed mill or cattle farm, you should pay attention to the following main processes:

Due to the influence of various objective factors such as cattle feed raw materials, processes, formulas, project area, local regulations, etc., various technological cattle feed production process and cattle feed equipment configurations have appeared in the actual cattle feed plant design.

Therefore, if you want to build a high-efficiency, high-quality, high-return cattle feed production line, please do not hesitate to contact Richi Machinery and communicate directly with our engineer team, you will definitely get a satisfactory answer. The following is the cattle feed mill machine configuration display of cattle feed production business plan we have done in several customer project :

| cattle feed making machine name | Model | QTY |

|---|---|---|

| Bale breaker | MPKJ170*225 | 1 |

| cow grass cutting machine |

TDSJ120*600 |

1 |

| cattle feed grinder | 9FQ50-100 | 1 |

| cattle feed mixer machine |

SLHY.1 |

1 |

| cattle feed pellet machine(with force feeder) | SZLH-M450 | 1 |

| cooling machine | SKLN11x11 | 1 |

| Auxiliary equipment: Belt conveyor*TDSJ100*600, U-Screw conveyor*TLSSU30, Bucket Elevator*TDTG40/23, Cyclone*SK600, Pulse dust collector*TBLMa.36b, Vibrating screener*TDZS80, Automatic Packing machine*DCS-50, MCC Control Center ;Mimic control panel, etc. | ||

| Complete cattle feed production line price: 100000-180000USD | ||

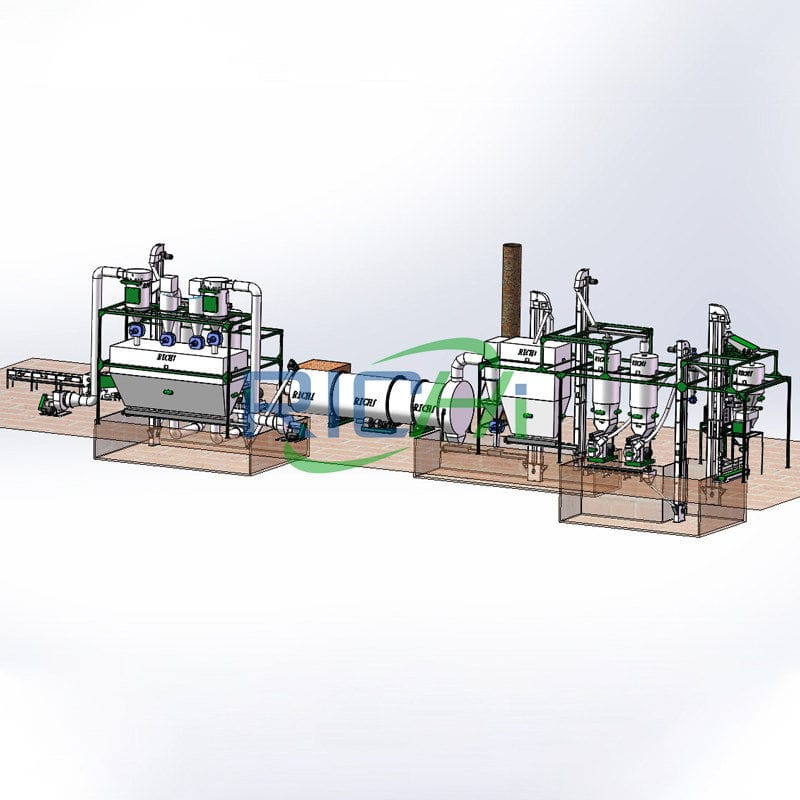

| cattle feed machine name | Model | QTY |

|---|---|---|

| cattle feed grinder machine | TDSJ120*600 | 2 |

| drum dryer | ф2400*100000*3 Layer | 2 |

| single shaft double ribbon mixer | SLHY5.0L | 2 |

| cattle feed pellet machine(with force feeder) | SZLH508 | 3 |

| cooling Machine | SKLN20*20 | 1 |

| rotary screener | SFJH125*2C | 1 |

| Auxiliary equipment: Belt conveyor*TDSJ120*600, U-Screw conveyor*TLSSU40, Scraper conveyor*TGSU32, Bucket Elevator*TDTG50/28, Cyclone*ф800, Pulse dust collector*TBLMa.36b, Auto Packing machine*DSC-50, etc. | ||

| Cattle feed production line price: 500000-800000USD | ||

| Cattle feed manufacturing machine | Model | QTY |

|---|---|---|

| hammer mill for cattle feed | 9FQ56-120 | 1 |

| cattle feed mixture machine |

SLHY2.5L |

1 |

|

cattle feed pellet making machine(with force feeder) |

MZLH520 |

1 |

| cooling machine | SKLN20*20 | 1 |

| vibrating screener | TDZS100 | 1 |

| automatic packing machine | DCS-50 | 1 |

|

MCC Control Center;Mimic control panel |

/ |

1 |

| Auxiliary equipment: Belt conveyor*TDSJ120*600, Screw conveyor*TLSU30,Bucket Elevator*TDTG36/28, Cyclone*SK1000, Pulse dust collector*TBLMa.36b,Oil adding machine *YZTG100a,etc. | ||

| Cattle feed production line price: 130000-250000USD | ||

| Cattle feed manufacturing machine name | Model | QTY |

|---|---|---|

| grinder machine for cattle feed | 9F56*40 | 1 |

| cow food mixer machine | SLHY1.0A | 1 |

| cow feed pellet making machine(with force feeder) | SZLH250 | 1 |

| cooling machine | SKLN1.0*1.0 | 1 |

| vibrating screener | TDZS80 | 1 |

| packing equipment | DCS-50 | 1 |

| MCC Control Center;Mimic control panel | / | 1 |

| Auxiliary equipment: Winnowing cyclone*SK60, Screw conveyor*TLSS16, Screw conveyor*TLSS20, Storage bin*1m³, Cooling draught fan*4-72-3.6A, Cooling cyclone*SK60, etc. | ||

| Small cattle feed plant costing: 30000-70000USD | ||

The design of cattle feed production line is an important part of the basic construction of feed industry. Design work is inseparable from the development and industrialization of new processes, new technologies, new equipment and new products, whether it is the new construction, reconstruction and expansion of cattle feed mill plants.

After the cattle feed plant construction project is approved, the pre-design work and design work become the key to the construction. Design work plays a decisive role in speeding up the construction speed, ensuring the quality of construction and installation, saving investment, and obtaining the maximum economic and social benefits after completion.

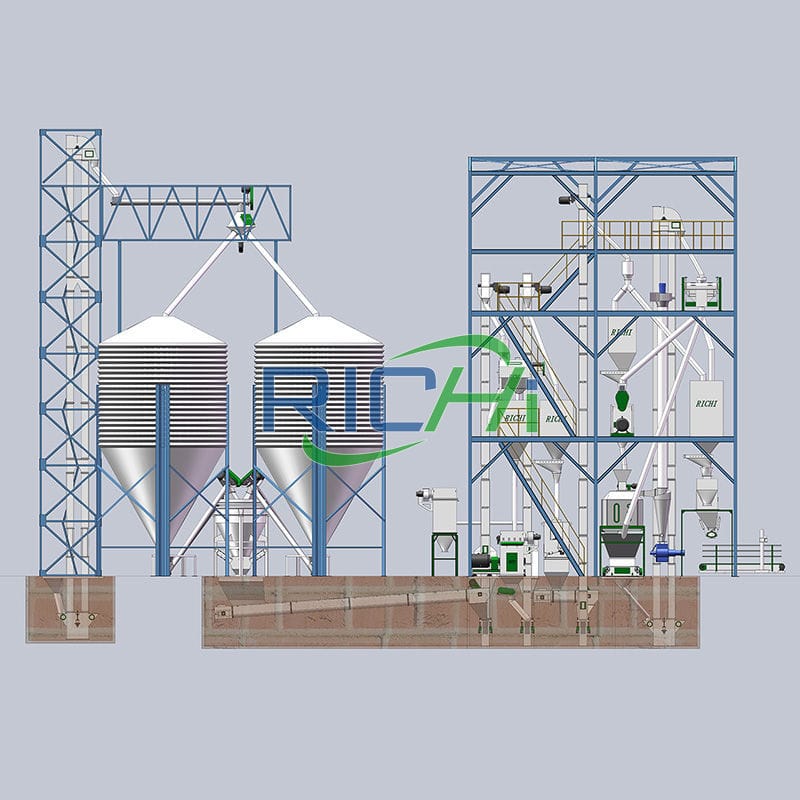

Each process starts with the reception of raw materials for cattle feed. Whether it is poured by hand or unloaded by tractor, truck or train – we will design a complete intake system for any bulk material that you need to create your feed.

After a thorough analysis, we use our wide range of storage options to create a solution for your mixed cattle feed process – all from a single source. This can include not only raw material storage prior to processing but also storing and buffering of ingredients and bulk materials within the cattle feed production process.

Our conveyors cover all applications throughout your feed value-added chain, from cattle feed raw material intake to conveying finished cattle feed pellets. We will customize a system to meet your space and cattle feed manufacturing technology needs, using any combination of elevators, trough chain, belt and screw conveyors as well as pneumatic conveying systems.

Our dust aspiration systems can be used along your entire feed value-added chain to meet all relevant market requirements. We can help you to avoid explosive atmospheres and protect your employees, environment and cattle feed manufacturing plant. Valuable fine product can be led back into the process stream, reducing cattle feed mill waste.

We can offer a wide range of solutions ranging from coarse, pre and main cleaning to primary sieving ahead of cattle feed grinder machines for different fractions as well as to separate fines before bagging.

The quality of your mixed feed essentially depends on the accuracy of the dosing and weighing of the ingredients in your recipe. Our solutions are designed to cattle feed and proportion each ingredient with the high precision you need.

With our versatile grinding portfolio, consisting of horizontal and vertical hammer mill for cattle feed as well as roller mills, we can cover all of your size reduction needs. We can bring you solutions for pre- and post-grinding, coarse and fine grinding, as well as for creating crumbles of various sizes.

Mixing plays a key role in the processing of your cattle feed. Our cattle feed mixer machines with different holding capacities and smart paddle design offer you a quick and precise mixing cycle. Optional liquid addition equipment can deliver the right liquidity too.

As a global cattle feed manufacturing technology leader, we fully understand how to pellet a wide range of materials. Our expertise focuses not only on creating cattle feed pellets, in partnership with you we strive for a process that improves the feed conversion rates, nutrition and safety of your cattle feed pellets.

The cooling of your hot pellets is essential for further handling and proper storage. Our extensive portfolio of countercurrent coolers offers you an efficient, hygienic and homogeneous cooling process. Different discharge systems ensure gentle handling with minimal fines tailored to your product.

The finish product contain pellet of normal size,smaller size and bigger size.By use grading sieve,we can get normal size pellet.As a total solution provider, we can offer you a range of customized concepts for bagging your finished mixed feed, ready for dispatch. Our automatic cattle feed plant packaging systems handle your bags very gently and achieve optimal stacking quality.

Be it in the form of pellets or mash we aim at highest cattle welfare and feed conversion rate. The technology underlying our cattle feed processing installations and the sound process expertise of our engineers will help you to produce cattle feeds to the most rigorous hygiene requirements, while mitigating cross-contamination.

Cattle feed processing equipment mainly includes bale breakers, forage grinders, mixers, stirrer equipment, hay cutters, grass kneaders, cattle feed pellet making machines, coolers, screening machines, baling scales, conveying equipment, cleaning equipment, dust removal equipment, Silo systems, automated control systems, etc.

RICHI are able to provide complete cattle feed pellet production line solutions, including total planning, civil engineering, steel construction, storage system, poultry feed pellet processing machinery, intelligent packing, electrical control system. RICHI has engaged in cattle feed machine for 25+ years and thus has rich experience on cattle feed machinery and cattle feed making plant after repeated attempts and trials.

Our cattle feed line solutions are simple and effective. We strive to be a "one-stop" all-round supplier for all pelleting needs. Whether it is individual feed making machines, complete cattle feed processing lines, or spare parts and services that you need - Richi Machinery will take you smoothly from raw material intake to finished feed bulk loading.

With the rapid development of the cattle breeding industry, cattle feed production lines, as an efficient and intensive production method, have gradually been favored by the industry. The purchase of cattle feed production line equipment is directly related to production efficiency and product quality.

Therefore, it is particularly important to choose a suitable equipment manufacturer. RICHI Machinery will explore the key factors that should be considered when choosing a cattle feed production line equipment manufacturer.

When choosing an equipment manufacturer, you must first understand its comprehensive strength. This includes the manufacturer's production scale, technical level, R&D capabilities, market reputation, etc.

You can visit the manufacturer's production base, understand its past project cases, and ask professionals in the industry to comprehensively evaluate the manufacturer's strength.

The performance of the equipment is directly related to the production efficiency and product quality of cattle feed. Therefore, when selecting equipment, its performance should be thoroughly investigated. Including equipment stability, degree of automation, production efficiency, energy saving and environmental protection.

At the same time, it is also necessary to consider whether the equipment meets the relevant standards and regulations of the country where it is located.

The after-sales service of the equipment is also an important part that cannot be ignored when choosing a manufacturer. Excellent manufacturers should be able to provide comprehensive after-sales service, including equipment installation and commissioning, operator training, regular maintenance, etc.

In addition, the manufacturer should be able to respond to customers' maintenance needs in a timely manner to ensure that the equipment can operate stably during the production process.

To choose a suitable cattle feed production line equipment manufacturer, you need to comprehensively consider the manufacturer's strength, equipment performance, after-sales service, price and cost-effectiveness, and innovation capabilities.

Only by comprehensive evaluation and careful comparison can you find the most suitable equipment manufacturer for yourself and provide strong guarantees for the long-term stable operation of cattle feed production.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.