Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

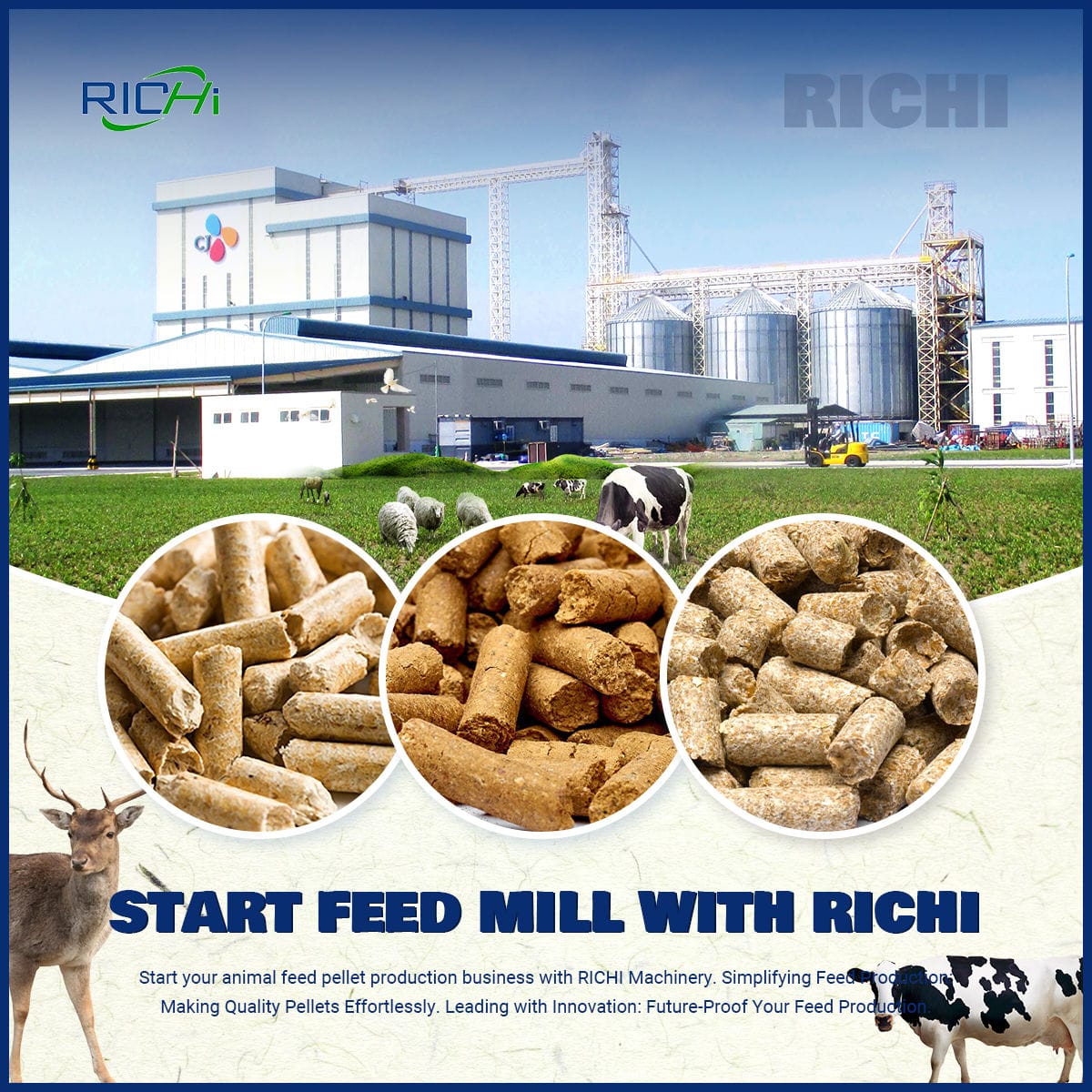

Ruminant feed pellet production line is a typical feed pellet processing system, mainly for the processing of animal feed such as cattle, sheep, camels, deer, etc. RICHI Machinery, as a pioneer and leader in ruminant feed equipment and feed mill engineering, is committed to tailoring professional forage processing, ruminant concentrate supplements, TMR total diet processing and other system solutions for the majority of ruminant feed factories, constantly innovating independently, upgrading processes and equipment, and continuously providing new development momentum for the ruminant industry!

Ruminant feed line can be used to process various types of ruminant feed, including cattle feed, sheep feed, camel feed, etc. It is mainly set up in ruminant feed mills, cattle feed mills, sheep feed mills, fermented feed mills, livestock feed mills, TMR feed mills or multifunctional animal feed mills.

Through reasonable raw material ratios and processing procedures, the ruminant feed line can produce high-quality and nutritious ruminant feed, thereby improving the efficiency and quality of ruminant farming. The system can also process other livestock and poultry feeds, and is a multifunctional feed processing system.

Ruminants, such as camel, deer, giraffe, alpaca, antelope, cattle, sheep, etc. Because these animals have complex ruminant stomachs, they are called ruminants. Ruminant feed is characterized by the addition of specific ingredients to the rumen rumen microbial environment, which can change and improve the ruminant rumen microbial environment and achieve the purpose of efficient use of feed and promotion of animal growth.

The characteristics of ruminant feed are its scientific formula, balanced nutrition, good palatability, and its ability to significantly increase the milk production and milk fat rate of ruminants, while promoting the effective digestion and utilization of protein.

Producing your own ruminants feed lowers your feed production costs and increases profit by using RICHI ruminants feed production lines.

Richi Machinery has many years of experience in designing and building ruminant feed production lines all over the world for ruminant feed mills or small and large ruminants farms from eg. 500-50.000 dairy cows/goat/camel/deer.

With the rapid growth of per capita consumption of beef, mutton and dairy products worldwide, the proportion of ruminant feeding and large-scale breeding has continued to increase, and various feed processors and breeders have also accelerated the development of the ruminant feed market.

RICHI has been committed to solving the pain points and difficulties in the ruminant industry. With the introduction of international advanced technology and the drive of independent innovation, it has continuously upgraded the ruminant feed process and equipment to win the first opportunity for major feed manufacturers in the increasingly competitive ruminant feed marke

In the design of ruminant feed production lines, RICHI adopts unique total diet processing technology, which can effectively reduce the formulation cost by 15-20%, increase feed utilization by 5-10%, and help feed manufacturers improve their overall benefits by more than 25%.

RICHI Machinery, as a pioneer and leader in forage ruminant feed equipment, has been committed to tailoring professional and systematic solutions for the majority of feed mills to help partners succeed!

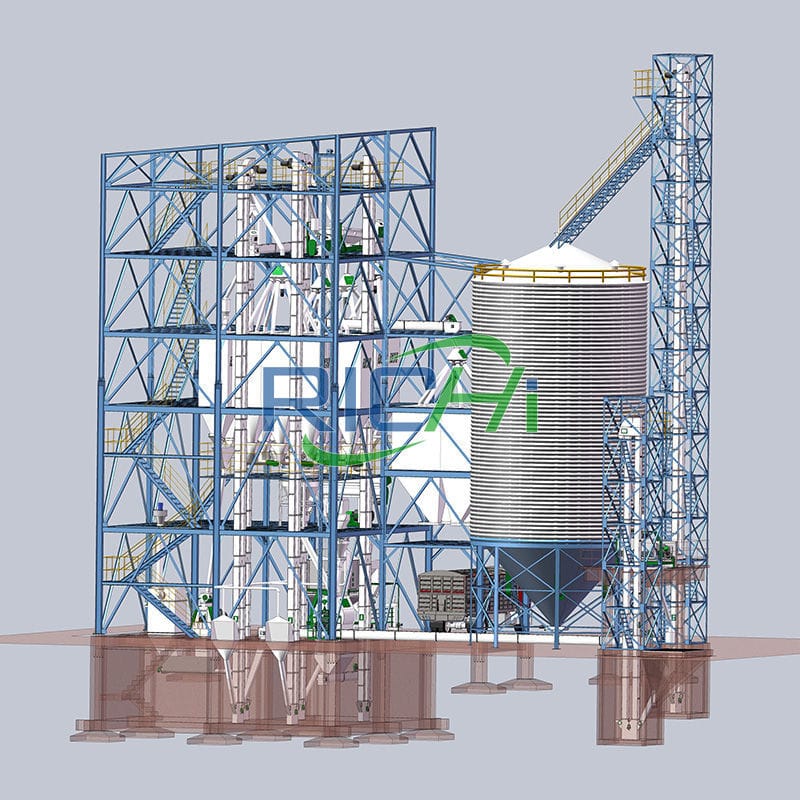

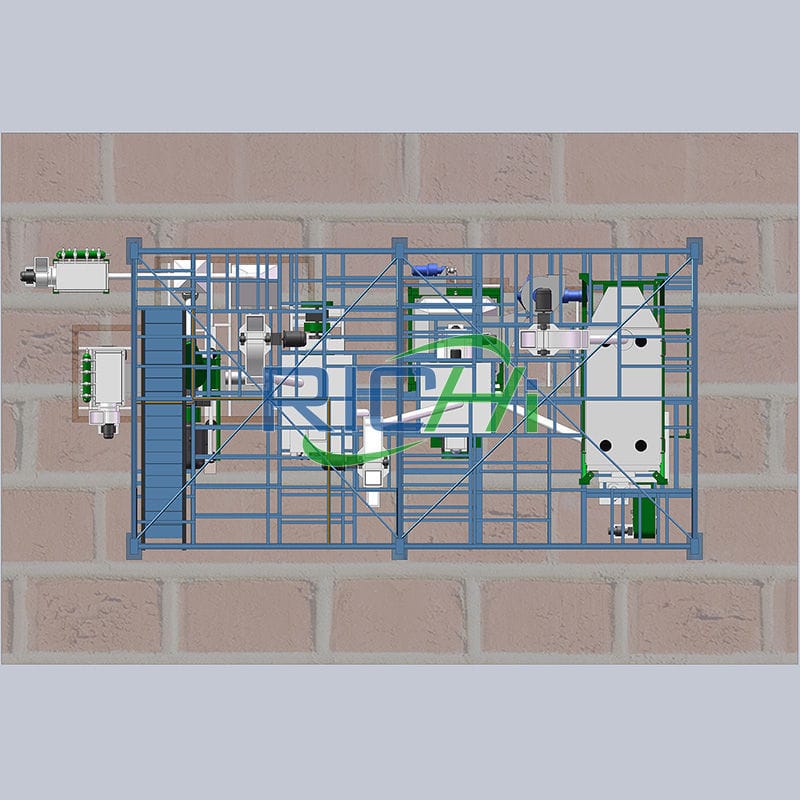

The configuration of the ruminant livestock feed production line is carefully designed according to the on-site survey or the actual requirements of the customer, which fully reflects the rationality, effectiveness, applicability, large output, low wear and low operating cost of the ruminant feed mill design. According to different technological requirements, various types of ruminant feed machinery are combined to meet customers' different ruminant feed manufacturing process requirements.

| Scale | Total Power | Site Requirements | Installation Cycle | ruminant Feed Mill Cost(USD) |

|---|---|---|---|---|

| 1-2T/H | 47-75KW | 300-500m² | 7-15 Days | 10000-50000 |

| 3-4T/H | 53-165KW | 300-700m² | 15-20 Days | 5,0000-12,0000 |

| 5-7T/H | 68-259KW | 400-800m² | 20-40Days | 7,0000-25,0000 |

| 8-10T/H | 125-410KW | 800-2000m² | 45-60 Days | 150,000-300,000 |

| 12-20T/H | 358-620KW | 1500-3000m² | 60-90 Days | 250,000-580,000 |

| 25-40T/H | 545-870KW | 2000-4000m² | 90-120Days | 45,0000-850,000 |

| 50-60T/H | 710-1120KW | 3000-5000m² | 100-140 Days | 900,000-1,400,000 |

| 60-80T/H | 815-1370KW | 5000-8000m² | 130-160 Days | 1,450,000-1,800,000 |

| 80-100T/H | 1230-1700KW | 8000-20000m² | 160 -190Days | 2,000,000-2,800,000 |

According to the regulations of the feed industry, ruminant feed factory construction projects can be divided according to the size of the production scale.

| Scale(t/h) | ≤2.5 | 5-10 | ≥20 |

|---|---|---|---|

| Factory type | small | medium | large |

| Capacity | Country |

|---|---|

| 10-12 T/H Cattle Ruminant Feed Plant For Hemp Pellets | America |

| 5T/H Cattle Ruminant Feed Plant For Alfalfa Pellets | Argentina |

| 3-5T/H Cattle Sheep Ruminant Feed Plant | Indonesia |

| 15-16T/H Cattle Feed Plant | Saudi Arabia |

| 10T/H Cattle Ruminant Feed Plant | South Africa |

| 3-4T/H Cattle Ruminant Feed Plant | Hong Kong, China |

| 10T/H Cattle Ruminant Feed Plant | Mauritania |

| 20-30 T/H Automatic Dairy Cow Feed Plant | Russia |

| 20-30 T/H Animal Feed Mill Plant | Pakistan |

| 0.8-4T/H Goat Cattle Ruminant Feed Mill For Wheat Straw Pellets | South Africa |

| 5-6T/H Livestock Sheep Goat Cow Cattle Ruminant Feed Plant | Somalia |

| 400,000T/A Animal Feed Production Line | Brazil |

| 12-15 T/H Animal Feed Mill | the Philippines |

| 16-20T/H Animal Feed Mill | UAE |

| 20T/H Animal Feed Mill | Indonesia |

| 3*25 T/H Animal Feed Mill | Vietnam |

| 8-10T/H Feed Mill Construction | Egypt |

| 15-20 T/H Feed Processing Plant | Argentina |

| 25T/H Custom Feed Mill | Uganda |

| 5-7T/H Complete Feed Mill Plant | Haiti |

| 40-50T/H Feed Mill Factory | Kazakhstan |

According to customer different ruminant feed production types, different output configuration can be customized. We devote ourselves to undertaking all ruminant feed production line with 1-100 tons per hour and to providing more value added service to all the customers.

Richi Machinery provides global customers with a one-stop, complete set of professional ruminant feed production line solutions (business plan for ruminant feed production) to solve the problems of customers, especially pure investment customers, such as technical difficulties and poor understanding of ruminant feed equipment, so that the needs and positioning of the project are more clear, and at the same time, the customer's equipment selection range is more concentrated, reducing the cost of energy and financial resources.

If you want to start a new ruminant feed pellet line for your ruminant feed mill or ruminant farm, you should pay attention to the following main processes:

Due to the influence of various objective factors such as ruminant feed raw materials, processes, formulas, project area, local regulations, etc., various technological ruminant feed production process and ruminant feed equipment configurations have appeared in the actual ruminant feed plant design.

Therefore, if you want to build a high-efficiency, high-quality, high-return ruminant animal feed pellet production line, please do not hesitate to contact Richi Machinery and communicate directly with our engineer team, you will definitely get a satisfactory answer. The following is the ruminant feed mill machine configuration display of ruminant feed production business plan we have done in several customer project :

| ruminant feed machine in 2-3t/h ruminant feed plant(Dryed Bale Straw/Hay) | ||

|---|---|---|

| ruminant feed making machine | Model | QTY |

| Bale breaker | MPKJ170*225 | 1 |

| ruminant grass cutting machine |

TDSJ120*600 |

1 |

| ruminant feed grinder | 9FQ50-100 | 1 |

| ruminant feed mixer machine |

SLHY.1 |

1 |

| ruminant feed pellet machine(with force feeder) | SZLH-M450 | 1 |

| cooling machine | SKLN11x11 | 1 |

| Auxiliary equipment: Belt conveyor*TDSJ100*600, U-Screw conveyor*TLSSU30, Bucket Elevator*TDTG40/23, Cyclone*SK600, Pulse dust collector*TBLMa.36b, Vibrating screener*TDZS80, Automatic Packing machine*DCS-50, MCC Control Center ;Mimic control panel, etc. | ||

| Complete set ruminant feed making machine price: 100,000-180,000 USD | ||

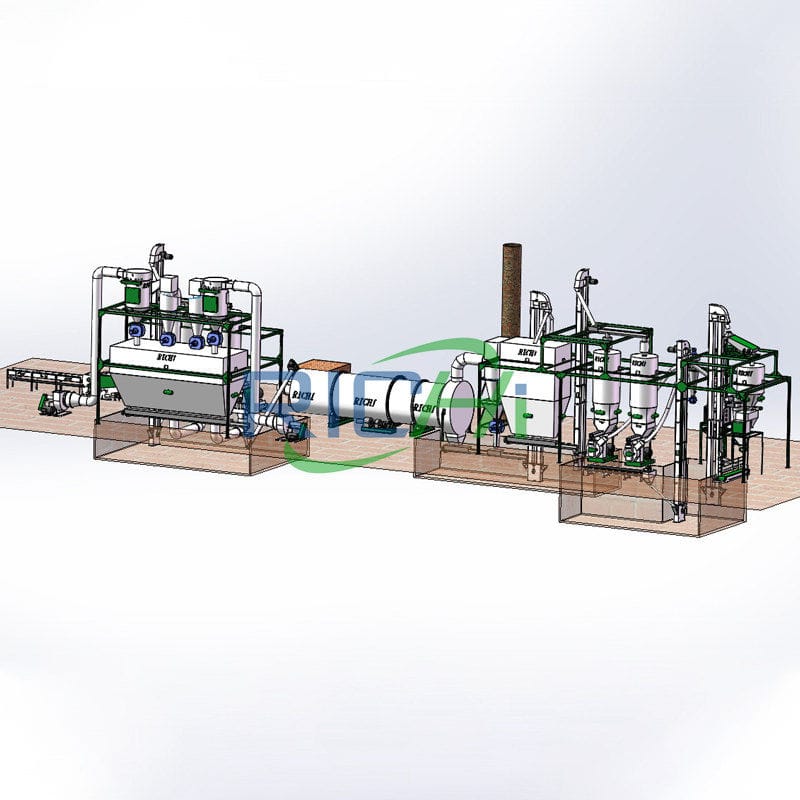

| ruminant feed machinery in 10t/h ruminant feed mill(70-90% Fresh Grass) | ||

|---|---|---|

| ruminant feed machine name | Model | QTY |

| ruminant feed grinder machine | TDSJ120*600 | 2 |

| drum dryer | ф2400*100000*3 Layer | 2 |

| single shaft double ribbon mixer | SLHY5.0L | 2 |

| ruminant feed pellet machine(with force feeder) | SZLH508 | 3 |

| cooling machine | SKLN20*20 | 1 |

| rotary screener | SFJH125*2C | 1 |

| Auxiliary equipment: Belt conveyor*TDSJ120*600, U-Screw conveyor*TLSSU40, Scraper conveyor*TGSU32, Bucket Elevator*TDTG50/28, Cyclone*ф800, Pulse dust collector*TBLMa.36b, Auto Packing machine*DSC-50, MCC Control Center ;Mimic control panel, etc. | ||

| ruminant feed making machine price: 500,000-800,000 USD | ||

| ruminant food making machine in 6t/h ruminant feed manufacturing plant(60% Straw/Alfalfa) | ||

|---|---|---|

| ruminant feed machine name | Model | QTY |

| hammer mill for ruminant feed | 9FQ56-120 | 1 |

| ruminant feed mixture machine |

SLHY2.5L |

1 |

|

ruminant feed pellet making machine(with force feeder) |

MZLH520 |

1 |

| cooling machine | SKLN20*20 | 1 |

| vibrating screener | TDZS100 | 1 |

| automatic packing machine | DCS-50 | 1 |

|

MCC Control Center;Mimic control panel |

/ |

1 |

| Auxiliary equipment: Belt conveyor*TDSJ120*600, Screw conveyor*TLSU30,Bucket Elevator*TDTG36/28, Cyclone*SK1000, Pulse dust collector*TBLMa.36b,Oil adding machine *YZTG100a,etc. | ||

| Ruminant feed making machine price: 130,000-250,000 USD | ||

| 0.8-1.2T/H small ruminant feed plant machinery | ||

|---|---|---|

| Ruminant feed manufacturing machine name | Model | QTY |

| grinder machine for ruminant feed | 9F56*40 | 1 |

| ruminant food mixer machine | SLHY1.0A | 1 |

| ruminant feed pellet making machine(with force feeder) | SZLH250 | 1 |

| cooling machine | SKLN1.0*1.0 | 1 |

| vibrating screener | TDZS80 | 1 |

| packing equipment | DCS-50 | 1 |

| MCC Control Center;Mimic control panel | / | 1 |

| Auxiliary equipment: Winnowing cyclone*SK60, Screw conveyor*TLSS16, Screw conveyor*TLSS20, Storage bin*1m³, Cooling draught fan*4-72-3.6A, Cooling cyclone*SK60, etc. | ||

| Small ruminant feed machine price: 30,000-70,000 USD | ||

Firstly, the ruminant feed raw materials will go through the crushing and grinding process, and they will be processed into powder and then mixed completely. Then, through the ruminant feed pellet machine, the mixed feed mash will be made into ruminant pellets. After the cooling process, the feed pellets can pack directly.

There are many types of ruminant feeds and many processes. In some processes, multiple crushers and conveyors are required to process bales; in some processes, fermentation processes are also required to process fermented ruminant pellet feeds; In some processes, since the raw materials added are not dry grass powder but grass or straw with high moisture content, a drying process is required, etc.

The following is a relatively basic and standard ruminant feed production line process:

In this initial phase the supply of substances for the desired recipe is determined. Normally a reception pit is foreseen where the raw materials are delivered. Through extraction screws and elevators the substances are loaded in the storage silo.

The ruminant feed raw materials are conveyed by a screw to the scale where they are weighed and dosed for the creation of the requested recipe.

The material that needs to be smaller, passes through a ruminant feed hammer mill machine, in order to reach the desiderable dimension.

The product is loaded in a horizontal feed mixer where it will be mixed and homogenized for a certain period; in this phase other micro-components can be added, like integrators or additives, necessary to the ruminant feed recipe.

The product is now ready and could be stored for delivery or sent to the ruminant feed pelletizing machine system.

The material is entering in the ruminant feed pellet mill passing through the pellet making machine conditioner. Here other ingredients like steam, molasses and grease could be added, before the material goes into the pellet pressure chamber to be transformed into pellets by the ring die. On the outside of the holes some knives cut the ruminant feed pellets at the desired length.

After pelleting, the product is very hot, therefore it's necessary to cool the product at approximately +5°C in respect to the room temperature, in order to give it the right hardness and the best consistence to store and handle it.

In the screening section the product is cleaned from the dust, which is brought back into the production cycle.

The pelleted product is conveyed to the silo for storage before delivery. It can be delivered in bulk, loaded on trucks or packed in sacks or big-bag. The automatic feed bagging machines for packaging could be manual, semi-automatic or automatic, based on the requested ruminant feed production.

In summary, ruminant feed is a special feed that is beneficial to animal digestion and absorption, can improve the production performance of ruminants, reduce production costs, and reduce the impact on the environment.

In recent years, the application of ruminant feed has become more and more extensive and has become an important part of the livestock and poultry farming industry.

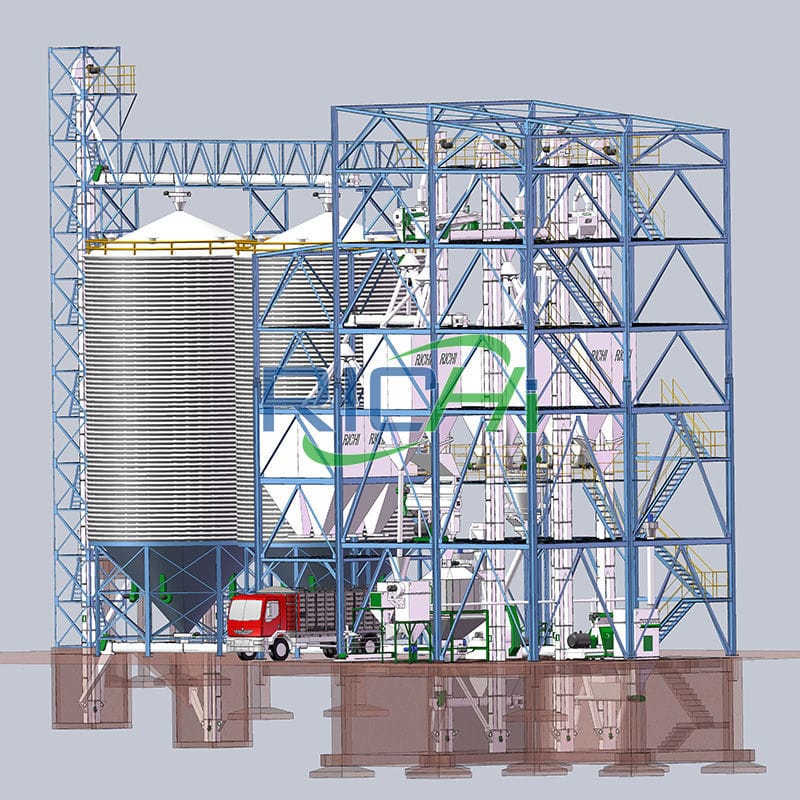

Process design is an important part of ruminant feed factory design and the core of capital construction projects. It is the design of related technical solutions for processing raw materials or semi-finished products into finished products. Its design scope is mainly the production system composed of ruminant feed production workshop, raw material warehouse and finished product warehouse.

The process design of the ruminant feed factory mainly involves the design of the ruminant feed mill process flow; the design of the production workshop and the layout of the equipment; the design of the ventilation network; the configuration of the ruminant feed raw material warehouse and the finished product warehouse, and the layout of the pipeline systems such as pneumatics, steam, and power distribution. The ruminant feed production line design can generally be completed in two stages: preliminary design and construction design.

The ruminant feed manufacturing plant process design involves a wide range of aspects and should be fully considered. In addition to considering the content of the process design category, attention should also be paid to maintaining close collaboration with non-process engineering aspects such as civil design and electrical engineering design, and to put forward the necessary process requirements to get corresponding and effective cooperation.

In order to specifically implement the requirements of "advanced technology, economical and reasonable, safe and practical, and quality assurance" in the engineering design of the ruminant feed pellet production line, the process design should follow the following basic principles:

The ruminant feed production line shall be set up separately, and the animal feed production equipment shall not be shared with other non-ruminant animal feed production lines. This can effectively prevent the occurrence of cattle and sheep-derived components in ruminant feed, prevent cross-contamination in ruminant feed plants, and ensure the quality and safety of ruminant feed products.

According to the unique digestive and physiological characteristics of ruminants and the nutritional requirements of feed, cattle and sheep feed is very different from pig and poultry feed in terms of feed formula and feed preparation technology. For example, ruminants can ferment food in the rumen and have more crude fiber. The impact is not large, so the crude fiber raw materials added to the feed for the production of ruminants will be more. In this way, if a monogastric animal feed production line is used, it is easy to break the feed making machine.

The ruminant feed pellet production line can improve production efficiency through the following aspects:

The processing of seeds is generally done by:

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.