Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

The cattle feed pellet making machine is an equipment that uses ring die granulation technology to process pelletized cattle feed. It is suitable for grass, alfalfa, hay, elephant grass, cereals, straw, bagasse, hemp, hops, oat husks, sunflower seed husks, peanuts shells and other raw materials. Depending on the cattle feed processing technology adopted by the customer, our cattle feed pellet machine can be used to process grass pellet feed, whole grain pellet feed, grain cattle pellet feed, fermented feed pellets, silage pellet feed, etc.

RICHI cow feed pellet making machine is suitable for use in cattle feed factories and farms with a scale of 1t/h or above.

The cattle feed pellet machine is mainly composed of a feeding device, a pressing device, a regulating device, a cooling device and an electronic control system.

Its working principle is: the feed raw materials enter the pressing device through the feeding device, and through the rotation and extrusion of the rollers, the feed raw materials gradually form into granules. During the pressing process, moderate moisture and temperature can enhance the plasticity of the feed and form uniform particles with appropriate density.

The cow feed pellet making machine mainly consists of the following structures:

The cattle feed pellet mill is an indispensable equipment in the feed processing industry. It has obvious functions, outstanding advantages and wide application. The processed feed pellets have stable quality and balanced nutrition, which is conducive to maintaining animal health and improving production efficiency.

| model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1~2 | 3~4 | 5~7 | 8~12 | 10~18 | 15~25 | 20~30 | 25~40 | 28~45 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~12 | ||||||||

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor |

||||||||

Currently, our cattle feed making machines have been exported to the United States, Russia, Argentina, India, Brazil, Germany, France, Saudi Arabia, New Zealand, Uzbekistan and other countries.

Cattle feed pellet machine used: SZLH 520

Cattle feed pellet machine used: SZLH 508

Cattle feed pellet machine used: SZLH 420

Cattle feed pellet machine used: SZLH 420

Cattle feed pellet machine used: SZLH 858

Cattle feed pellet machine used: SZLH

Cattle feed pellet machine used: SZLH 250

Cattle feed pellet machine used: SZLH 508

According to the needs of different customers, we have provided a complete set of cattle feed machines to customers in more than 100 countries around the world, including pasture cattle feed pellet equipment, alfalfa pellet equipment, hemp cattle feed pellet equipment, cattle feed mixing plant equipment, corn cattle feed plant equipment, cattle silage feed making machine, fermented cattle feed equipment, cattle mash feed plant equipment, etc.

Generally speaking, the cow feed pellet making machine cost ranges from US$10,000 to US$100,000.

Fluctuations in the price of cattle feed pellet making machines are affected by multiple factors, including raw material prices and market supply and demand conditions. Here is an analysis of these two factors:

01

Price of raw materials:

02

Market supply and demand:

In addition to raw material prices and market supply and demand conditions, other factors may also affect the price fluctuations of pellet machine for cattle feed, such as labor costs, technological innovation, degree of competition, etc.

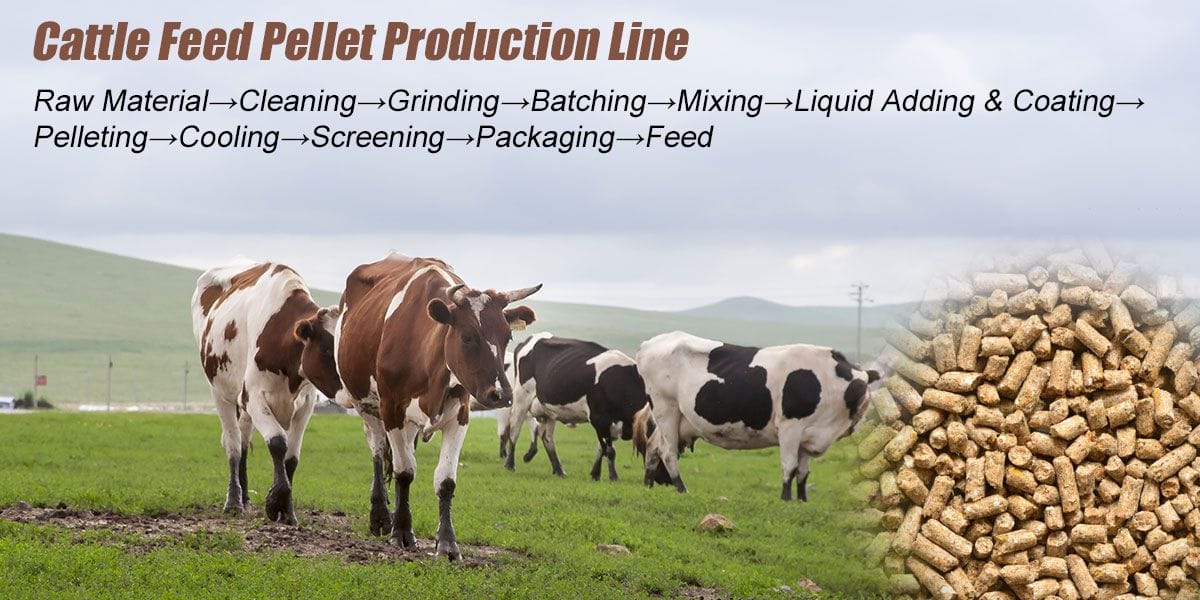

How is cattle feed pellet processed? This requires a complete cattle feed processing system with the cattle feed pellet making machine as the core. (Here we take the processing of full-dairy grass pellet cattle feed as an example)

The RICHI cattle feed pellet mill line with ce adopts a patented process design and is equipped with a patented cattle feed pelletizing machine; the addition amount of grass meal reaches 40~60% and the addition amount of molasses reaches 5~12%, which fully meets the needs of cattle rumination and promotes its rapid growth.

A complete set of cattle feed pellet engineering, comprehensive nutrition, safe and environmentally friendly. Different processing techniques are customized for different raw material formulas to achieve differentiated value with high feed return rates.

The following are the main steps of the granulation process of the cattle feed mill unit:

01

Raw material preparation:

02

Crushing and Selection of cow feed pellet mill

03

Mixing:

04

Pelleting and forming:

05

Cutting and cooling:

06

Screening and grading:

07

Packaging and storage:

The cattle feed production process requires scientific planning and operation in the selection of feed raw materials, pelleting process, additive selection, and sealing of production links. Only by paying attention to every detail can we produce high-quality cattle feed and provide strong support for the healthy development of cattle.

The entire cattle feed pellet plant production process requires a high degree of equipment coordination to ensure the uniformity, stability and palatability of the feed pellets to meet the feeding needs of different cattle. Optimization of the granulation process will help improve the production efficiency and sustainable development of the breeding industry.

Cattle feed processing equipment mainly includes bale breakers, forage grinders, mixers, stirrer equipment, hay cutters, grass kneaders, cattle feed pellet making machines, coolers, screening machines, baling scales, conveying equipment, cleaning equipment, dust removal equipment, Silo systems, automated control systems, etc.

01

Conveying equipment

02

Cattle feed crushing equipment

03

Batching equipment

04

Other equipment

The selection of raw materials for cattle feed is very important. Common feed raw materials include silage, corn, alfalfa, soybean cake, wheat bran, etc. During the selection process, you need to consider the nutritional content of the feed and pay attention to avoid the impact of mildew, foreign matter, etc. on the cattle.

The pelleting process is an essential link in cattle feed production. Generally speaking, the granulation process is divided into two types: pressing method and extrusion method. Among them, the pressing method with cattle feed pellet making machine is fast and suitable for economical mass production; the extrusion method has good granulation quality and is suitable for high-end breeding.

In short, cattle pellet feed adopts advanced production technology and provides farmers with a more considerate feeding choice with multiple advantages such as scientific formula, pelleting technology, drying technology, quality control, environmental protection and energy saving.

In the breeding industry, the cattle feed pellet machine is one of the essential equipment. However, how to choose a suitable cattle feed pellet machine is a task that requires comprehensive consideration. Here are some key factors when choosing a cattle feed pellet machine to help you make an informed decision.

01

First, you need to consider your cattle feed production size, breeding scale and production needs.

02

Secondly, you need to consider the quality and nutritional content of the cattle feed.

03

You also need to consider the reliability and durability of the cattle feed pellet machine.

04

You need to consider the energy consumption and environmental performance of the cow feed pellet machine.

05

You can learn more about the performance and characteristics of different brands and models of cattle feed pellet mills by understanding word-of-mouth and professional reviews in the industry.

In short, choosing a suitable cattle feed pellet making machine requires comprehensive consideration of multiple factors, including feed mill scale, breeding scale and production needs, feed quality and nutritional content, reliability and durability, energy consumption and environmental performance, etc. .

By thoroughly understanding the features, pros and cons of different brands and models, and talking to professionals, you can make an informed decision about choosing the right cattle pellet machine. This will help improve your production efficiency and quality, reduce operating costs, while also helping protect the environment and sustainable development.

In a modern cattle feed processing plant, the cattle feed pellet making machine is one of the indispensable equipment and the key equipment in the cattle feed production line.

Therefore, you need to consider many aspects when purchasing equipment. There are many manufacturers of cattle feed pellet mills on the market, and the quality of the equipment they sell varies. How to choose a reliable manufacturer to cooperate with? RICHI Machinery recommends that you consider these aspects:

Taking the above factors into consideration and conducting adequate research and comparisons can help you choose the right cattle feed pellet making machine manufacturer. In addition, it is also important to establish long-term cooperative relationships with manufacturers, because a good cooperative relationship may provide you with better support and cooperation opportunities.

During the decision-making process, you may wish to communicate and negotiate with multiple manufacturers to obtain more information in order to make a wise choice.

With the acceleration of the development of agriculture and animal husbandry, the cattle feed industry is gradually developing and growing. It not only provides guarantee for the energy needs of livestock, but also provides important support for agriculture and animal husbandry, especially the agricultural and animal husbandry industry chain.

By 2030, the cattle feed industry will enter a new stage of sustained growth, further improve the industrial structure, promote industry upgrading, improve market competitiveness, and exert considerable economic benefits.

By 2030, the development of agriculture and animal husbandry will continue to accelerate, and the cattle feed industry will enter a new stage of sustained growth. From feed production to feed technology, technological progress will quickly play a positive role in the cattle feed industry.

At the same time, as the policy environment continues to improve, the cattle feed industry is expected to achieve large-scale operations and establish or accelerate the improvement of feed manufacturing technology.

It is expected that by 2030, the cattle feed industry will be more developed. There will be more and more varieties of high-quality cattle feed, and the structure will become more and more optimized. This will bring considerable development opportunities and benefits to the cattle feed industry.

In addition, it can not only meet the energy needs faced by today's livestock, but also solve the technical problems raised by the development of the agricultural and animal husbandry industry chain, promote industry upgrading, improve market competitiveness, and enhance social contribution.

In the future, the cattle feed industry will have greater development. The government needs to introduce policies to encourage the research and development of cattle feed, seize the opportunities of technological development, and encourage enterprises to invest in the research and development of various machinery and equipment to improve processing efficiency, improve quality, control costs, and timely update technology and expand exports to promote the sustainable development of the cattle feed industry.

In short, the cattle feed industry will face good development prospects in the future, with large room for improvement. The marketing model will be gradually optimized, quality and safety will be improved, and new technologies will continue to promote the development of enterprises and help the healthy breeding of livestock..

It will help promote the development of agriculture and animal husbandry, improve the economic market situation and livestock breeding services, and achieve sustainable development.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.