Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

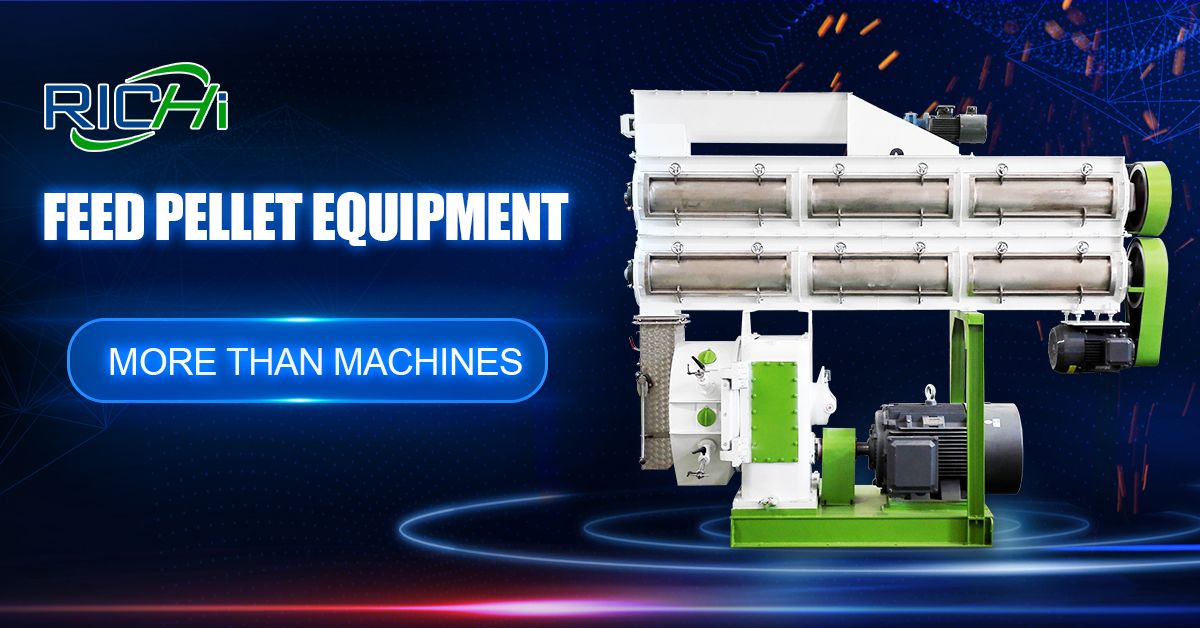

The goat feed pellet making machine is an efficient feed processing equipment, mainly used to process goat and sheep feed pellets in different growth periods. This equipment is suitable for processing a variety of goat sheep feed pellets such as timothy pellets, hay pellets, grass pellets, alfalfa pellets, beet pulp pellets, organic goat pellets, soy hull pellets, teff grass pellets, etc., and applies different goat sheep feed formulas. Currently, our goat sheep feed pellet machines are widely used in various types of goat feed mill, sheep feed production line, ruminant feed factories, livestock feed production lines and sheep goat farms.

Sheep goats are one of the indispensable livestock in our lives. The products they provide such as goat milk, mutton and wool are closely related to our lives. Because goat sheeps are ruminant animals, the pellet feed produced by the feed pellet machine can facilitate the rumination of the goat sheep and reduce digestive tract diseases in the goat sheep.

The pellet feed compressed by the goat sheep feed pellet maker machine can significantly shorten the growth cycle of the goat sheep and increase the feed intake by 15%. The goat sheep fed with pellet feed are about 10 kilograms heavier than the goat sheep raised extensively, and the slaughter time will be corresponding. months in advance. This is undoubtedly a huge benefit for goat sheep farming.

| Model | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Ring Die Compression Ratio | Pellet Length (mm) | Pellet Diameter (mm) |

|---|---|---|---|---|---|---|

| SZLH250 | 1.5-2.5 | 22 | 0.75 | 1:6:1:9 | 12-18 | 6~12 |

| SZLH320 | 4-5 | 37 | 1.5 | |||

| SZLH350 | 6-8 | 55 | 1.5 | |||

| SZLH420 | 10-13 | 110 | 1.5 | |||

| SZLH508 | 12-18 | 160 | 2.2 | |||

| SZLH558 | 22-28 | 180/200 | 2.2 | |||

| SZLH678 | 28-32 | 220/250 | 2.2 | |||

| SZLH768 | 32-38 | 280/315 | 2.2 | |||

| SLZH858 | 42-48 | 280/315 | 2.2 |

Currently, our goat feed making machines and sheep feed pellet production line have been exported to the United States, Russia, Argentina, India, Brazil, Germany, France, Saudi Arabia, New Zealand, Uzbekistan and other countries.

Goat feed pellet machine used: SZLH 520

Goat feed pellet machine used: SZLH 508

Goat feed pellet machine used: SZLH 420

Goat feed pellet machine used: SZLH 420

Goat feed pellet machine used: SZLH 858

Goat feed pellet machine used: SZLH 768

Goat feed pellet machine used: SZLH 250

Goat feed pellet machine used: SZLH 508

According to the needs of different customers, we have provided a complete set of cattle feed machines to customers in more than 100 countries around the world, including pasture cattle feed pellet equipment, alfalfa pellet equipment, hemp cattle feed pellet equipment, cattle feed mixing plant equipment, corn cattle feed plant equipment, cattle silage feed making machine, fermented cattle feed equipment, cattle mash feed plant equipment, etc.

The price of goat pellets machine is generally between 10000-100000 USD.

What factors affect goat feed pellet machine cost?

Each of the above factors, including the product mix and the stage of the product in the final enterprise, will affect the price of the goat feed pellet making machine. The enterprise needs to comprehensively consider these factors before formulating an appropriate price strategy to create a good situation for the enterprise.

When choosing a goat sheep feed pellet machine, there are several factors to consider to ensure you choose the right equipment for your needs.

Here are some suggestions:

To sum up, when choosing a goat sheep pellet machine, you need to comprehensively consider factors such as production needs, raw material type, equipment quality, energy consumption and efficiency, brand and service, and price to ensure that you choose the equipment that best suits your needs.

The followings will introduce “how to make goat feed pellets”.

The main components of feed pellets are forage and concentrate. The forage can be silage corn straw, rice straw, alfalfa, grass meal, etc. The concentrate can be dregs, bran, bean cake, fish meal, protein powder, etc. When selecting raw materials, attention should be paid to the different characteristics of the goat sheep such as breed, age, gender, season, etc.

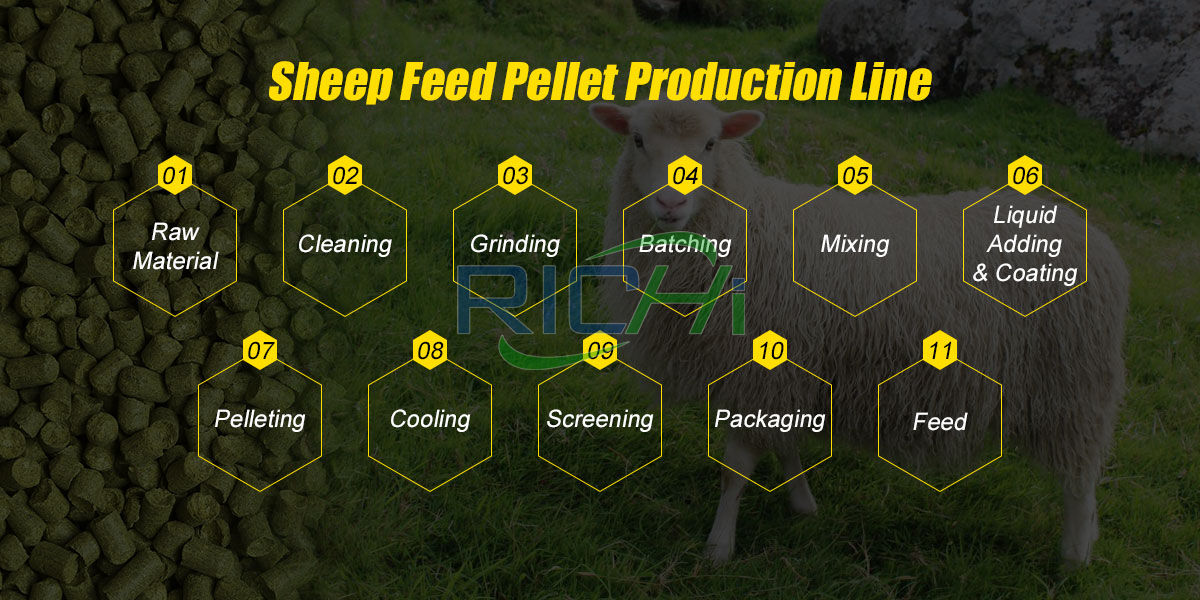

Production process of goat and sheep feed pellets:

01

Preparation of raw materials for particle production

02

Mixing of crushed material

03

Pelleting

04

Cooling treatment

05

Packaging and storage

By making goat pellet feed, the feed utilization rate of goat and sheep can be improved and waste reduced. At the same time, it can ensure that animals receive balanced nutrition and improve production efficiency. Pellet feed can also reduce environmental pollution and reduce the impact of livestock and poultry breeding on the environment.

Goat feed making machine is selected based on production scale, production varieties and production technology. Therefore, the equipment used in different goat feed mills is different. However, the basic goat feed equipment for goat and sheep feed processing is the same and can be roughly divided into the following parts according to the process flow:

Different production scales, process requirements, raw materials, formulas and product types require different equipment. If you want to start a sheep feed processing business, contact us to get a detailed sheep feed factory equipment configuration plan!

With the rapid development of the breeding industry, there is an increasing demand for efficient, environmentally friendly and safe feed products. The complete set of goat feed processing machine just meets this demand.

With the continuous advancement of science and technology, the complete set of automated and intelligent goat food making machine will be more advanced and intelligent, providing a more powerful and intelligent solution for the development of animal husbandry.

There are the following reasons for choosing RICHI Machinery as your goat feed making machine manufacturer:

The above content is the reason for choosing RICHI Machinery, and you can also better evaluate and select a suitable goat feed pellet making machine manufacturer to meet your needs and obtain reliable equipment and services.

Before making a decision, it is recommended to compare and contrast with multiple manufacturers to ensure you make an informed choice.

In investment in goat sheep raising, feed costs generally account for about 70% of the total cost of breeding. In order to save feed resources, produce high-quality and low-cost sheep feed, and achieve the purpose of large-scale healthy and efficient sheep raising, let's share some ideas on designing sheep Some things to note when formulating feed:

Before formulating goat sheep feed, you should understand the stage, gender, weight and physiological condition of the sheep to determine the sheep feed formula for which stage to achieve what effect.

The growth of goat sheep is inseparable from three major categories of nutrition: energy, protein, vitamins and minerals. For the supplement of vitamins and trace elements, you can choose compound multi-dimensional and trace elements, additives, and sheep premixes at different growth stages.

When designing goat sheep feed formulas, we must fully consider the comprehensiveness and balance of each nutrient, master the nutritional characteristics of various feeds, scientifically match each other, and supplement each other. The deficient part must be made up by additives to prevent excessive imbalance of certain nutrients.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.