Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

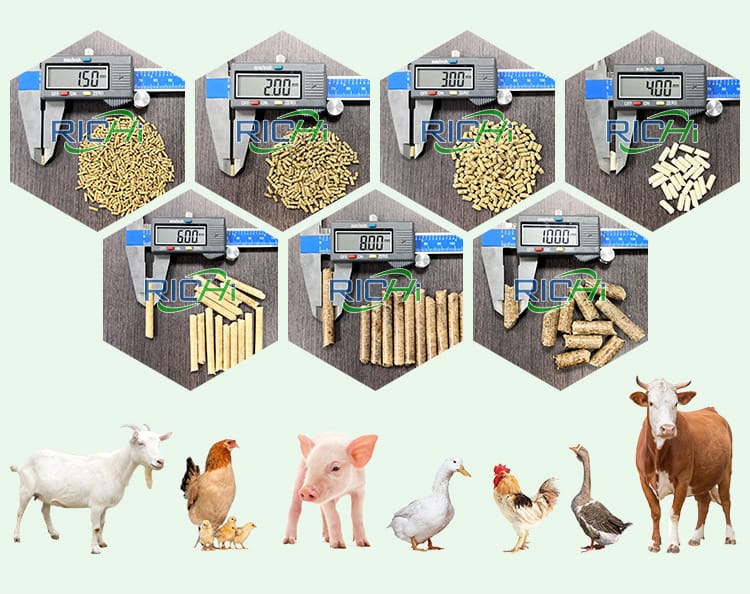

Livestock feed pellet machine is mainly used to process various pellet feeds of 2-12mm for cattle, sheep, pigs, rabbits, horses, camels, deer, donkeys, etc. It is suitable for any feed formula and raw materials. Due to the different types of feed materials, the pellets size is also different, and there are different requirements for the performance and structural parameters of the livestock pellet making machine. The livestock feed pelleting process is generally equipped with granulating, cooling and screening equipment, and some are also equipped with a grease spray system.

This type of livestock feed pellet making machine can be used for the processing of livestockfeeds such as pigs, cattle, sheep, rabbits, horse, deer, camel, etc. It can also be used for the processing of other feed pellets, such as poultry feeds, aquatic feeds, etc., by adjusting the design of the conditioner and other pellet machine components.

Livestock feed pellet mill is mainly used in various livestock feed production lines, compound feed plants, cattle feed production lines, pig feed plants, sheep feed production lines, rabbit feed plants, horse feed mill plants, etc.

Livestock pellet making machine for making grass feed, maize feed pellets, fermented feed, silage pellets, etc.

Livestock feed pellet maker machine for making alfalfa pellets, hay pellets, timothy pellet, flock feed, etc.

Stock feed pellet machine for making hog starter feed, hog finisher feed, pig creep feed, fattening pigs feed, sow feed, etc.

Livestock pellet machine for making alfalfa pellets, grass hay pellets, timothy hay pellets, organic rabbit feed, high fiber rabbit pellets.

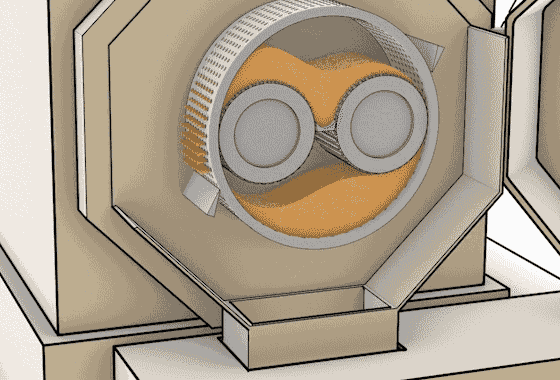

The working principle of the livestock feed pelletizer: The livestock feed pelletizing machine is a process of compacting the powdered feed and extruding the die hole into the pellet feed. First, the powdered compound feed is tempered with steam or water, and then compressed into columnar pellets with a feed pelletizer, and then the position of the cutter is adjusted to obtain the desired pellet size.

The above content is the working principle of a single livestock feed pellet forming machine, but generally speaking, the livestock feed pellet maker does not work alone, and is mainly used in the animal feed production line of the farm or the production line of the feed factory. The pellet feed made by livestock feed pellet milling machine requires a uniform size, with a diameter of about 3-20mm, a length of 1.5-2 times the diameter, a smooth surface, no cracks, and a compact structure.

The pellet feed has different diameter requirements for different livestock. In the production of pellet feed, there are several things we should pay attention to, because it will affect its forming and quality.

In modern livestock sheep pig cattle feed mills, the ingredients are usually stored in bins above a weighing system composed of one or more scales. Those ingredients which are of coarse texture, such as whole grains and other fibrous materials, are ground into a fine meal to facilitate the pelleting and mixing process.

Weighted quantities of each ingredient (either as a batch or continuously) are thoroughly mixed (either in a batch mixer of a continuous flow mixing unit) and then conveyed to a bin above the livestock feed pellet mill.

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1~2 | 3~4 | 5~7 | 8~12 | 10~18 | 15~25 | 20~30 | 25~40 | 28~45 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~12 | ||||||||

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor |

||||||||

Livestock Feed Pellet Making Machine Price: FOB 7,000-100,000USD.

What's Livestock feed pellet machine price? Because different customers have different requirements for pellets, there will be many differences in the details of our feed pellet machine design. Therefore, the actual feed pellet maker machine price for different livetock feed machine projects are different. Even if the customer wants to produce the same type of pellets, if the customer's feed formula, raw materials, and production technology are different, the livestock fodder pellet making machine ring die, conditioner, etc. will be different.

The productivity and quality of livestock pellet feed. In addition to being related to the performance of livestock feed pellet machine, it depends largely on the pelleting performance and pelleting process of raw materials. Due to the difference in process control and operation level, the productivity and production quality can be greatly different.

The pelleting performance of livestock feed raw materials refers to the difficulty of pressing raw materials into pellets. Raw material characteristics include material capacity, particle size, fat, protein, fiber, water, starch content, and friction and corrosiveness. These factors will be related to the productivity of pellet feed and will affect the quality and quality of pelleting.

Raw materials with large material capacity have higher pelleting output and lower energy consumption than raw materials with small material capacity. A livestock feed pelleting machine with a main motor of 55kW uses cottonseed cake powder (capacity of 640kg/m3) as raw material. The pelleting productivity is several times that of alfalfa powder (bulk density of 270kg/m3) as raw material.

The particle size of the raw material determines the surface area of the feed components. Fine particles have large surface areas and absorb moisture from steam quickly. It is conducive to moisture regulation and easy to press into livestock feed pellets.

The high efficiency of pelleting reduces the wear on working parts. Large particle size will increase the wear of the die and roller, resulting in poor pelleting quality, increased energy consumption, and low output.

The moisture content of the raw material has a significant impact on the production volume and quality of livestock pellet feed. Adding a certain amount of water or steam during the pelleting process can form a thin layer of water on the outside of each particle of the material, making it easy for the particles of the material to bond and pass through the hole die.

On the other hand, it can also dilute the natural adhesive in the raw material, thereby effectively improving the pelleting performance of the raw material. The moisture content of the raw material should be around 13%. If the moisture content of the raw material is too high, it will be difficult to control the addition of moisture during pelleting, and the addition of steam will also affect the increase in pelleting temperature.

The natural protein and fat content in feed raw materials also have a great influence on the pelleting effect and productivity. If the natural protein content in the livestock feed is high, the capacity is large, the plasticity is good after heating, the viscosity is improved, the pelleting output is high and the quality is good, but when the non-protein nitrogen (especially the amount of urea) is high, the pelleting efficiency decreases, and the fat completely loses its cohesiveness, which seriously affects the livestock feed pellet machine pelleting effect.

In addition, it is also beneficial for the raw material itself to contain moderate fat, which can reduce the wear of the pelleting parts and make it easier for the material to pass through the hole die; if the fat content in the raw material is too little, 0.5%~1.0% oil can be added. If excessive oil is added (more than 2%), the pellets will soften and loosen rapidly, thereby reducing productivity.

At the same time, attention should be paid to the fiber content and heat-sensitive feed content in the feed raw materials. When the fiber content is high (10%~15%), the hardness and forming rate of the pellets are affected due to poor viscosity.

Although the latter becomes more viscous after being heated, which can reduce the pulverization rate of the pellets, it will start to coke when the temperature is higher than 60℃, which may cause the die hole to be blocked in severe cases.

In the production of livestock pellet feed, the granulation performance of the overall raw materials can be evaluated according to the physical and chemical properties of the main raw materials in the feed formula, so as to select the corresponding most suitable processing conditions to ensure that the pelleting productivity requirements are met and the overall performance of the raw materials after livestock granulator pelleting is improved.

The process conditions required for livestock feed pellet machine mainly refer to the rationality of process arrangement and the perfection of operation technology during pellet pressing process. It mainly includes several factors such as feed flow control, steam quality control, pelleting conditioning time control, etc.

In order to make the pellet machine work evenly and at full load during pelleting process, the material flow entering the feeder of livestock feed pellet machine must meet the pelleting needs, especially the feed structure should effectively eliminate the intermittent feeding phenomenon caused by arching and other reasons, and control the actual feed amount by adjusting the speed of the feeder in actual production.

In order to ensure the stability of the material flow entering the feeder, a more reasonable arrangement is to install a storage hopper directly above the livestock feed pellet machine. The hopper capacity should be about 1/4 of the hourly requirement of the livestock feed pelleting machine. The powder mixed evenly in the previous process is directly entered into the hopper through the chute after being lifted. If this buffer hopper is not set, it is difficult to ensure the stability of the material flow.

Many operators only look for reasons for the livestock pellet making machine itself when the pelleting productivity is abnormal, but ignore the incoming material factors. In fact, in many cases, the decline in productivity is caused by unstable incoming material flow.

Using steam pelleting can effectively improve the output and pellet quality of livestock feed pellet mills, but how to ensure the quality of saturated steam entering the stock feed pellet machine modulator is a very important factor. Generally speaking, the temperature of powdered feed after steam conditioning before pressing pellets is not less than 70℃, and the moisture content is about 15.5%. At this time, the pelleting effect is better.

If the room temperature is about 25℃ and the average moisture content of the raw material is 12%, then after conditioning, the temperature increases by more than 45℃ and the moisture content increases by about 3.5%. Taking the livestock feed pellet machine productivity of 5t/h as an example, briefly explain the relationship between the heat and moisture changes between steam and materials

When the room temperature is 25℃, the temperature of the material can exceed 62℃ after absorbing 175kg of saturated steam. In addition, the increase in material temperature is also affected by other factors:

In fact, after the steam enters the conditioner, it will consume a considerable amount of mass and heat due to contact with air and steel parts; When the moisture and temperature of the material are too low, more steam should be added. Under normal circumstances, it is reasonable to calculate the steam consumption according to 5% to 6% of the maximum productivity of the livestock feed pellet machine.

The applicable saturated steam pressure is specified as 0.2 to 0.4 MPa. When the pressure is too low, the conditioning index cannot be achieved within the specified conditioning time; when the pressure is too high, the steam temperature is also high.

And the heat conduction heating phenomenon of the steam through the conditioner components to the material is significantly accelerated, which is easy to cause defects such as high material temperature, low moisture, and local material burnt, affecting the pelletizing quality.

The conditioner is a key component of the livestock feed pellet machine. Its structure is similar to that of an ordinary screw conveyor. It uses an adjustable paddle-type spiral blade with a speed of 300~400rpm.

By adding steam from the steam inlet on the barrel and stirring vigorously, the material is heated and watered in a short time and then transported to the pressing chamber of the livestock pellet machine. In addition to the addition of steam, the conditioning time is also an important factor in the material conditioning effect.

The ideal conditioning time is the residence time of the material in the conditioner when the material filling coefficient is not less than 0.5 and the conditioning conveying volume meets the pelletizing requirements. Due to the size limitation of the livestock pellet mill, it is impossible to make the diameter and length of the conditioner too large in order to extend the conditioning time.

However, the residence time of the material in the conditioner can be appropriately extended or shortened by adjusting the angle between the blade and the transmission shaft.

When changing the die with different apertures, the operator can adjust the blade angle according to the actual productivity to obtain the required conditioning time. If the die of different die holes is changed frequently, it is not advisable to adjust the blade frequently to avoid taking up too much production time.

Especially when the raw materials are relatively rough, such as vegetable cake, cottonseed cake, grass powder accounts for a large proportion, and the material particle size is large, the conditioning time should be guaranteed as much as possible to soften the material, reduce resistance, and improve the pelleting quality and productivity.

In short, to obtain the best yield and the best quality pellet feed, we must master the pelleting performance of the raw materials and select the most suitable process conditions and livestock feed pellet machine with good performance to obtain the highest productivity and superior quality of pellet feed.

The quality of raw materials is the key to the quality of livestock pellet feed products. Moldy, deteriorated, counterfeit, or harmful raw materials that exceed the standard will affect the quality of pellet feed and feeding effect, such as moldy bean cake, fake methionine and adulterated fish meal, calcium hydrogen phosphate with fluoride index exceeding 0.18%, etc. will affect the quality of livestock pellet feed.

Natural protein has good plasticity under the action of heat and has a viscosity-increasing effect. Raw materials with high content of protein have better quality pellets, such as soybean meal. However, when non-protein nitrogen (such as urea) is high, the pellet quality is reduced.

Starch has a high density and can be gelatinized under the action of water and heat. It has strong adhesion, so pellet feed is easy to form. In addition to the degree of gelatinization affecting adhesion, the type of starch and its proportion in the formula also affect the pelleting performance.

Generally, the adhesion of powdery starch is greater than that of keratinous starch. For example, the adhesion of barley and wheat starch is greater than that of corn and sorghum; formulas with too high starch content are difficult to press out solid and durable pellets.

This is because too high starch content will inevitably reduce the protein content, and the pelleting performance of the livestock feed pelletizer will be affected. It is worth noting that if natural starch has been gelatinized before pelleting (such as dried corn), high-quality pellet feed cannot be produced. Therefore, it is better to purchase non-dried feed.

Fiber itself has no adhesiveness, but the raw material contains an appropriate amount of fiber (3%~5%) to play a role in the pelleting of livestock feed pelletizers. Raw materials with more fiber are lighter and take longer to pass through the ring die, so the pellets are harder.

However, if the crude fiber content in the raw material is too high (>10%), it will cause the pellets to break, the compression is not tight, the pellet wall is uneven, and the mechanical wear is large, and the production efficiency is low; feed raw materials with high fiber content cannot meet the basic conditions of the assumption and requirement of "plastic body" during the extrusion process.

It has poor compressibility and the powder is difficult to adjust its position during the extrusion process, causing the extrusion layer between the die and the roller to move in the negative direction of the roller movement, resulting in difficulty in pelleting.

For pressing materials with more fiber, such as rice bran and leaf powder pellets, due to the loose and porous interior, low-moisture materials with a moisture content of 12%~13% and low-temperature pelleting at 55~60℃ are suitable. If the moisture content of the material is high and the pelletizing temperature is high, the pellets will expand rapidly and crack after leaving the mold.

Fat (including those inherent in the raw materials or added from the outside) has a significant effect on the pelleting output and quality: fat has a side effect on the formation of pellets. Adding 1% to 3% fat will significantly increase the output of the livestock feed pelletizer and reduce the loss of the die roller.

However, if the fat exceeds 3%, it will act as a loosening agent, resulting in low feed hardness and high powdering rate. If a large amount of fat needs to be added, 30% of the total amount of fat can be added at the mixer outlet and 70% can be applied to the outside after pelleting.

If some materials are selected as fat carriers, such as soybeans and rapeseed, a considerable amount of fat can be added without affecting the hardness of the livestock feed pellets.

In order to enhance palatability and increase the caloric value of the feed, molasses such as "lactase sugar" are usually added to the raw materials. When the amount added is not large, it can improve the particle bonding effect, but when added too much, it is easy to soften and break the particles.

At the same time, feeds with high molasses content have an impact on steam conditioning, because only a little or no steam can be added when pelleting high-molasses feed; cattle feed is a typical feed with a low grain level. The addition of liquids such as molasses in large amounts can lead to high power consumption and low steam consumption.

After hydrothermal treatment, heat-sensitive substances (sucrose, glucose, skim milk powder, whey powder, etc.) become more viscous, increase the hardness of the particles, and reduce the powdering rate. However, when overheated (>60℃), they are easy to coke and become too sticky, which will clog the ring die holes.

In this case, the amount of steam added to the livestock feed pelletizer should be controlled or a thin ring die should be used. If the proportion of heat-sensitive substances is too large, it will often clog the die holes. In this case, the method of reducing the amount of steam added and adding oil should be adopted.

Including mineral ores, etc. Such materials have no adhesion, are not conducive to molding, have high friction, are corrosive, wear the ring die, and even block the die holes, reducing productivity, such as stone powder, calcium hydrogen phosphate, bone powder, etc. However, zeolite, bentonite, etc. have a large cavity surface area and have a bonding effect.

In order to ensure the quality of the particles, the moisture content of the material must be limited to a certain extent. There are two types of moisture: the moisture contained in the raw material itself and the moisture added. The moisture content of the raw material itself should be 12%~13%; for high-fiber, high-natural protein concentrates, the moisture content should not exceed 13%~14%.

Generally, the total moisture content of the material is preferably 16%~18%, and the optimal mold entry temperature is 75~90℃; when saturated steam is introduced, the material temperature rises by 11℃ for every 1% increase in moisture content; if the moisture content of the raw material is too high, the steam volume should be reduced, otherwise the raw material temperature cannot reach the optimal mold entry temperature, which will also affect the quality of the pellets.

Binders are also called granulation additives. Commonly used binders include clay, bentonite, lignin sulfonate, polymethyl urea, α-starch, etc.; adding binders can reduce dust loss during granulation, reduce breakage after granulation, improve granulation molding rate and pellet hardness, and increase pellet firmness. Cow and rabbit feeds do not contain (or contain a small amount of) wheat.

Therefore, in the formulation, an additional binder such as bentonite can be used to improve the durability of the pellets. However, bentonite increases the friction of the ring die, which slows down the speed of the material passing through the ring die and increases the die pressure, which leads to increased energy consumption and increased production costs.

In addition to the bonding effect, some binders also have a lubricating effect, such as lignin, a byproduct of cellulose processing, and soluble plant gum (such as guarla gum), which can be used for die lubrication without interfering with the bonding between livestock feed particles. Since the material can easily pass through the ring die, the energy consumption of pelleting is reduced.

Generally speaking, raw materials with a larger bulk density have a higher yield and less energy consumption than raw materials with a smaller bulk density. Usually, when the bulk density of the feed is 0.55t/m3, the pelleting performance of the livestock feed pelletizer is good; when it is 0.55t/m3, the livestock feed pelleting performance decreases.

The above are the precautions for making pellet feed with livestock feed pellet mill. Finally, we remind everyone that pellet feed should be properly kept after production, and attention should be paid to moisture, ventilation and rodent prevention to prevent feed from mildew and loss.

In order to improve the sanitary requirements and palatability of feed, the simplest and most direct method is to pelletize the feed. This livestock feed pelleting technology has been widely used in the production of livestock. With the increasing improvement and perfection of feed production equipment, the production cost is reduced. Further reduction, the application range of feed pelleting technology will also become wider and wider.

In addition to the above-mentioned advantages of pelletizing feed, pelletized feed by livestock feed pellet machine is convenient for long-distance transportation and long-term storage, avoiding picky eaters by animals, so to a large extent, it can also significantly improve the digestion and utilization of nutrients in the livestock feed.

Almost all livestock feeders agree that animals make better gains on pelleted feed than a meal ration. The most logical reasons are that the heat generated in conditioning and pelleting make the feedstuffs more digestible by breaking down the starches, the pellet simply puts the feed in a concentrated form, and pelleting minimizes waste during the eating process.

When pelleted feed is fed, each animal receives a well-balanced diet by preventing the animal from picking and choosing between ingredients. Tests have shown that most animals, if given the choice between the same feed in pellet or mash form will prefer the pellets.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.