Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

The premix feed mill is a feed production system specialized in processing premixes. The entire premix feed production line adopts scientific design technology, professional production equipment and high-end stainless steel materials. It combines the different needs of customers, directional design, reasonable layout, efficient production and rapid production to help customers seize market opportunities. While meeting individual needs, we also provide one-stop services from entire premix feed plant planning, premix process selection, equipment selection, installation and commissioning to operation training, maintenance, and subsequent upgrades.

Premix is the abbreviation of additive premixed feed. It combines one or more trace components (including various trace mineral elements, various vitamins, synthetic amino acids, certain drugs and other additives) with diluents or carriers as required. The intermediate compound feed product is made after uniform mixing.

As a high-tech enterprise, RICHI Machinery aims at international high-end premix technology and uses leading new premix processes to provide premixes, additives, acidifiers, sweeteners, antifungal agents, silica, methionine and feed vitamins. and other manufacturers in different industries provide exquisite equipment and comprehensive system solutions.

(In addition to premix processing, the RICHI premix feed mill can also be used for the processing of food additives. Food additives refer to food additives that are added to food to improve food quality, color, aroma, and taste, as well as for the needs of antisepsis, preservation, and processing technology. Synthetic or natural substances, including preservatives, thickeners, antioxidants, sweeteners, flavors and fragrances, pigments, etc.).

According to the classification of conveying methods, the premix production line provided by RICHI has two modes: mechanical conveying and pneumatic conveying.

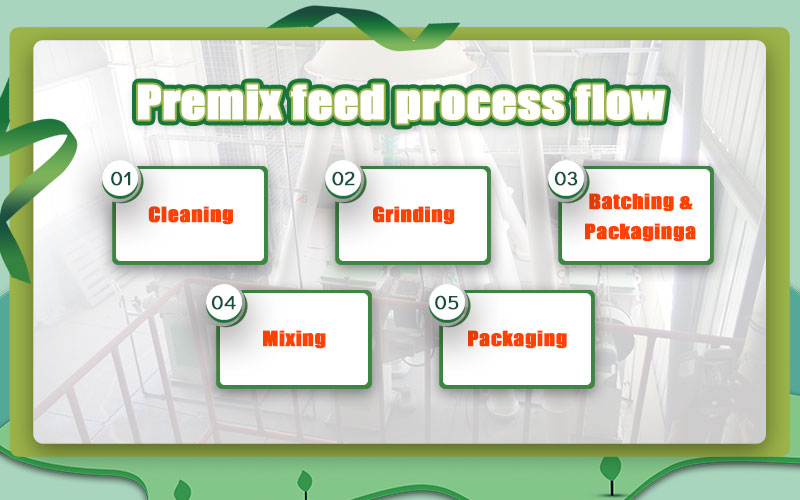

Generally speaking, the process flow of a premix feed mill includes: raw material receiving, automatic cleaning, directional dust removal, intelligent storage, efficient mixing, precise batching, automatic packaging and palletizing, etc.

The premix feed production process is affected by factors such as raw material varieties, formulas, production types, premix feed plant structures, funds, etc. It requires directional design based on the actual conditions of different customers to design a solution that best suits them.

01

Raw material reception:

02

Automatic cleaning:

03

Directional dust removal:

04

Efficient mixing:

05

Precise ingredients:

06

Automatic packaging and palletizing:

07

Electronic control system:

We focus on the research, design, manufacturing and installation services of various premix feed mill projects, tailor-made for global customers, integrating raw material receiving, automatic cleaning, directional dust removal, intelligent storage, efficient mixing, precise batching, automatic packaging and palletizing.

A complete set of premix feed production lines for premixed feed additives and food additives, and strives to create a "safe feed, safe food" premix project to promote healthy breeding and food safety.

In short, the RICHI premix feed production line process and equipment selection need to be scientifically designed and reasonably configured to deliver a safe, clean, green and environmentally friendly complete project to customers.

RICHI takes customer needs as the core, relies on high-tech products, and takes lifelong service as its commitment, and continues to create more and greater personalized value for customers of the premix feed mill, and achieves "mutual benefit, win-win, and common development" with customers. ".

At present, our premix feed mill equipment has been exported to Thailand, El Salvador, the United States, Vietnam, Russia, Argentina, Brazil, Indonesia and other countries.

Premix feed mill is an important part of animal feed production. It can mix feed raw materials according to a certain proportion and add appropriate amounts of additives to produce feed that meets the requirements.

The design and manufacture of premix feed plant equipment needs to take into account many factors, such as the characteristics of raw materials, production capacity, product quality and production safety, etc.

Premix feed mill equipment usually includes the following main parts: raw material storage and transportation system, batching system, mixing system, additive system and finished product packaging system. These parts work together to ensure a smooth production process.

The performance and reliability of premix feed mill equipment have an important impact on the quality and efficiency of feed production. Therefore, when designing and manufacturing premix production line equipment, various factors should be fully considered to ensure the performance and reliability of the equipment.

At the same time, during the premix feed production process, the premix feed making equipment should be maintained and maintained regularly to ensure the long-term stable operation of the equipment.

01

Dust control

Most of the materials processed in the premix feed mill workshop are powders with very fine particle sizes that are easily inhaled into the human body, which is detrimental to the health of workers and cannot pass environmental protection requirements. Therefore, dust removal devices must be installed at each feeding port and packaging port for directional dust removal.

02

Made of stainless steel

Regardless of the process, starting from the premix feed mixer, adding hoppers for small materials to packaging, all parts in contact with the materials need to be made of stainless steel, which can effectively prevent corrosion.

03

Automatic batching

Premixes have very high requirements for batching accuracy. The accuracy of the batching scale must reach the standard of 0.1% dynamically and 0.3% statically.

04

Mixer

The effective volume of the main mixer in the premix workshop is at least 1 cubic meter. It uses a stainless steel double-shaft paddle mixer and a single-shaft paddle mixer. The mixing efficiency is high, the residue is low, and the uniformity is high.

05

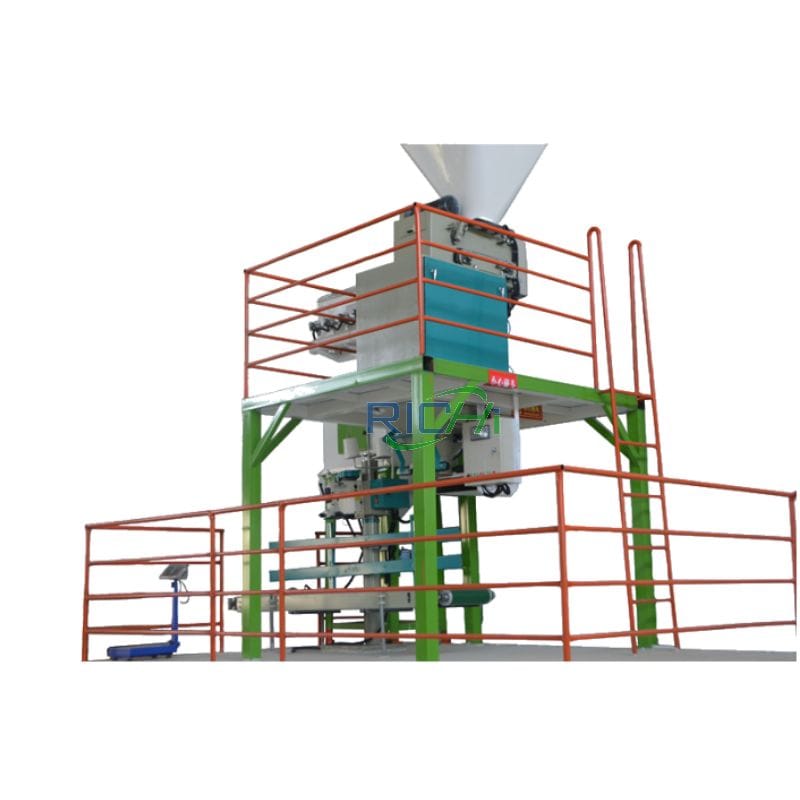

Automatic packaging

It is recommended that the premix feed mill workshop use automatic packaging and palletizing. Manual packaging not only has low precision and efficiency, but also increases labor costs and serious dust leakage, affecting the health of operators.

Before premix companies build new premix feed production plants, they need to scientifically select their own processes and equipment in advance, which will have a great impact on subsequent production.

01

Adopt advanced formula

Formula is the core premix feed mill technology of premixed feed. It needs to be carefully proportioned by professional animal nutrition experts based on the characteristics of animal growth and nutritional needs at each stage, as well as many influences such as the external environment.

The ratio of active ingredients to diluent, the ratio of various trace elements, and the ratio of active ingredients in the premix should be just right. Sufficient scientific basis and practical experience are required. Otherwise, serious production consequences will easily occur.

02

Select high-quality raw materials

The basic requirements for high-quality raw materials are high purity, no harmful substances, and the content of active ingredients must be actually measured. When selecting trace element raw materials, the content, particle size, crystal water, toxic and harmful substances, etc. of the ingredients should be considered.

Medicinal additives should also pay attention to safety issues. In addition, some additives themselves will affect other ingredients, so special attention should be paid.

03

Use the best carrier and diluent

The carrier should be selected with strong stability, moderate particle size, and good mixability with complete feed. The carrier particle size is between 0.17~0.59mm, and the moisture content is controlled at 8%~10%. Commonly used carriers include: corn, bran powder, stone powder, salt, etc.

Diluents are substances that reduce the concentration of active substances in a premix and reduce reactions between active ingredients. The water content of the diluent should be less than 10%, the particle size should be between 0.05~0.6mm, and it must be edible and harmless to animals.

04

Use high-precision production equipment

Scientific proportioning is the first step, and the subsequent steps need to be achieved by accurate metering of ingredients. Premix production has high requirements for the accuracy, precision, and stability of various types of metering equipment, and requires the configuration of technologically advanced premix feed mill equipment.

And it is necessary to strengthen the daily management and regular calibration of relevant equipment.

05

Mix evenly

The mixing section of the premix is a key part for premix feed mill. If the uniformity is poor, it means that the actual content of the animal intake does not match the formula, which directly affects the feeding effect.

Therefore, equipment, mixing time and appropriate carriers or diluents must be scientifically selected to strive for uniform mixing. Especially for some ingredients whose safe measurement and poisoning measurement are not much different, insufficient mixing uniformity will directly cause feeding accidents.

With the continuous advancement of technology and increasing application requirements, premix feed mill design and manufacturing technology are also constantly developing and improving.

In the future, with the application and development of new technologies such as intelligence, automation and greening, premix feed production line equipment will be more efficient, reliable and environmentally friendly, providing better support and guarantee for the development of the feed industry.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.