Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Different fishes in different growing stages have different demands for fish feed pellet size, therefore, choosing the right fish feed production technology and fish feed pellet making machine is very important. Many fish feed companies are upgrading their fish feed production process and production capacity through new construction, addition of fish feed production lines, technological transformation, etc., to meet the opportunities and challenges of fish feed production market development.

In the process of pelletizing, the fish feed pellet making machine adopts the heat from friction for warming materials, forces materials to pass through fish pellet machine ring die hole and gets certain pressure simultaneously under the action of screw extrusion. After extruding out of fish pellet machine die hole, materials pressure will decrease sharply and moisture will evaporate so as to achieve the goal of fish feed extrusion.

The length of the single-channel conditioner of the ordinary feeder is short (about 2m), the material residence time is also short (about 20s), the starch gelatinization degree is not high, and it is only suitable for the production of livestock and poultry feed without special requirements. However, aquatic feed requires a higher degree of gelatinization and water stability.

For this purpose, a three-stage conditioner of aqua fish feed pellet machine can be used. As the total length is greatly increased (up to 8m), the residence time of the fish feed making material is also extended (up to 2min), and sufficient adjustment is required. The substance gelatinizes starch and denatures protein, which improves the digestibility and water resistance of fish feed pellet.

Therefore, it is best to use multiple conditioners of the fish food pellet making machine in the production of aquatic feed to ensure product quality. Another method is to adopt a post-curing process to allow the hot pellets just out of the fish food pellet making machine to continue for a period of time under high temperature and humidity to further gelatinize the starch.

Especially the starch on the surface, which is beneficial to further improve the fish pellet feed's performance of water resistance. When fish pellet feed is kept in the post-cooker for 12 minutes, the starch gelatinization rate can be increased from 33.3% to 53%. The Fish Feed Pellet Making Machine here is a kind of sinking fish feed machine, not floating fish feed machine. If you want to produce extruded fish feed, please check out our extruders page.

| Model | Capacity(TPH) | Main Motor Power(kw) | Feeder Motor Power(kw) | Conditioner Power(kw) | Dia.of Ring Die(mm) | Final Pellet(mm) |

|---|---|---|---|---|---|---|

| SZLH250 | 0.6-1.4 | 22 | 0.75 | 1.5 | 250 | 1.5~12 |

| SZLH320 | 1.8-2.8 | 37 | 1.5 | 2.2 | 320 | 1.5~12 |

| SZLH350 | 3-5 | 55 | 1.5 | 3 | 350 | 1.5~12 |

| SZLH420 | 4.8-8.5 | 90 | 1.5 | 7.5 | 420 | 1.5~12 |

| SZLH508 | 6-12.5 | 132 | 2.2 | 11 | 508 | 1.5~12 |

| SZLH558 | 9-17.5 | 180/200 | 2.2 | 11 | 558 | 1.5~12 |

| SZLH558D | 8.4-15.5 | 160/180/200 | 1.5 | 7.5 | 558 | 1.5~12 |

| SZLH678 | 12-21 | 220/250 | 2.2 | 11 | 678 | 1.5~12 |

| SZLH678D | 9-17.5 | 200/220/250 | 2.2 | 11 | 673 | 1.5~12 |

| SZLH768 | 15-28 | 280/315 | 2.2 | 11 | 768 | 1.5~12 |

| SLZH858 | 15-30 | 280/315 | 2.2 | 15 | 858 | 1.5~12 |

| Fish feed pellet making machine price: 10,000-100,000 USD. | ||||||

| 5-6T/H Trout Fish Feed Plant For Sale Russia | Uzbekistan 1T/H Floating Fish Feed Plant For Sale Uzbekistan (Tashkent) |

| 1T/H floating fish feed plant for sale Uzbekistan(Gizak) | 5T/H sinking fish feed mill for sale Uzbekistan |

| China 30000 Tons Per Year Feed Mill For Fish And Pet Feed Pellets | 25T/H Full Automatic Aqua Prawn Fish Feed Manufacturing Plant |

| 15T/H Aqua Feed Plant For Fish Prawns Crab Feed Production In China | 1T/H floating fish feed plant for sale Zimbabwe |

| Simple Design Small Fish Feed Pellet Line For Sale UK | Commercial Fish Food Making Machine For Sale Austria |

| Floating fish feed production line for sale Lithuania | Small 200kg/h floating fish feed production line Moldova |

| Wet fish feed making machine DSP-120B for sale Russia | 100-150kg/h floating fish feed plant foe sale Ukraine |

| 1T/H sinking fish feed plant Thailand | DGP-50 small electric fish food making machine for sale Singapore |

| DGP90-B floating fish food making machine for sale Turkmenistan | 1T/H Fish Feed Machine For Sale Puerto Rico |

| DGP80-B floating fish food making machine for sale Honduras | 2T/H floating fish feed extruder machine for sale Bolivia |

| Simple Design 2T/H Fish Feed Production Plant For Sale Bolivia | 1T/H Fish Food Making Machine For Sale Dominica |

| 150kg/h Small Floating Fish Feed Production Plant For Sale Tanzania | 1T/H floating fish feed plant in Senegal |

| 1T/H Fish Food Making Machine For Sale Senegal | 150KG/H Small Floating Fish Feed Mill Plant In Nigeria |

| 1T/H Fish Food Making Machine For Sale Nigeria | 1T/H Fish Food Making Machine For Sale Cote d'Ivoire |

| 150KG/H small fish feed mill plant for sale Burkina Faso | 70B fish food making machine for sale Cameroon |

| 150KG/H Small Floating Fish Feed Line For Sale Botswana | DGP90 Fish Food Making Machine For Sale South Africa |

| 40C small electric fish food making machine for sale Philippines | Small electric fish food making machine for sale Lebanon |

| DGP60-C floating fish food making machine for sale Pakistan | 500-600kg/h fish food making machine for sale UAE |

| 1T/H Fish Food Making Machine For Sale Mozambique | DGP50C Small Fish Food Making Machine For Sale Tashkent |

The above fish feed production line and fish feed machine project are real transaction information. If you want to get project-related information, pictures, and videos, please contact RICHI Machinery.

Before the fish pellet making machine is used for pelleting, the raw materials of fish feed pellet need to be crushed. For the raw materials that do not meet the crushing particle size requirements of the fish pellet making machine, it is impossible to process high-quality fish feed pellets.

Fish digestive organs are simple and short, and the ratio of digestive tract length to body length is much smaller than that of livestock and poultry. The ratios of digestive tract length to body length of pigs, chickens, cattle, and sheep are 14, 10, 26, and 27, respectively, while silver carp is 6, bighead carp is 5, grass carp is 2.5-3, carp is 2.5, and herring is 1.2 -2.0, mandarin fish is 0.6.

The digestive glands of fish are underdeveloped, and various digestive enzymes cannot fully exert their optimal activity due to low body temperature; there are few types of digestive bacteria in the intestines, and the number is not large; the residence time of food in the digestive tract of fish (food passing time or emptying time) is significantly shorter than livestock and poultry:

The finer pulverized particle size is beneficial to improve the digestion and absorption rate of nutrients by fish and shrimp, and is also beneficial to improve the mixing uniformity and particle forming rate of the fish feed pellet, and directly affect the stability of the fish food pellets in the water.

Because fish feed ingredients require fine crushing particle size, it is difficult for ordinary fish feed hammer mills to meet this requirement. At present, the water drop crusher for fish feed is an advanced type of fish feed grinding machine. It uses a unique design idea to form two hammer-screen gaps for ordinary crushing and fine crushing. The crushing particle size is finer and more uniform.

At the same time, the water drop crushing chamber can destroy the impact screening capacity of the circulating layer, thereby improving the crushing efficiency. If the production of special aquatic feed requires a finer crushing particle size, a micro fish feed grinding machine must be used for processing. The fine pulverization of aquatic feed often adopts the secondary pulverization process, that is, first coarse pulverization and then fine pulverization.

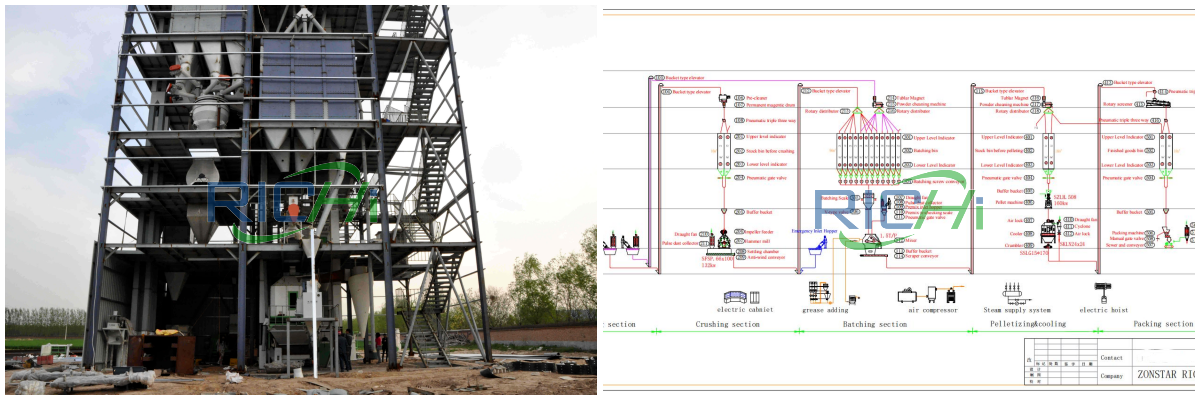

RICHI is unique in their ability to manufacture and supply every fish feed making machine for aqua feed production. With in-depth knowledge of each key procees of fish feed production, we provide a compatible and advantageous fish feed plant solution, from raw material intake to finished feed bulk loading.

Our packages are tailor-made to suit the specific requirements of our customers, whether it is our extensive knowledge or expert engineering along with individual fish feed processing machines, complete fish feed processing lines, or spare parts and service availability.

Complete fish feed making process to establish a fish feed mill

Fish feed pellet production how it works? In the fish feed production procedure, aquatic feed production has the following requirements for equipment and processing parameters.

In the cleaning section of the fish feed mill plant, since the amount of granular materials such as corn and barley are small in the aquatic fish feed processing line, and the powdery or fine granular materials such as fish meal and cakes are used in large amounts, the cleaning of powdered raw materials must be strengthened in the cleaning section.

On the one hand, it is necessary to ensure the cleaning efficiency of the powder cleaning equipment, and on the other hand, to ensure the fish feed plant's production capacity of the powder cleaning equipment.

The crushing section of a larger aquatic fish feed mill factory can adopt two-stage crushing. Conventional crushing first, and then fine crushing to reduce the working pressure of the fine crusher for fish feed and reduce the temperature rise of the material caused by crushing.

The material is classified between conventional crushing and fine crushing, and only the unqualified parts of the fineness are allowed to enter the fine crusher to increase crushing output and reduce crushing energy consumption.

The use of secondary crushing increases the flexibility of the crushing section. When producing certain adult fish feeds that do not require high raw material fineness, conventional fish feed grinders can be used alone for production.

In order to shorten the fish feed plant process flow and reduce fish feed plant equipment investment, a micro fish feed pulverizer can also be used for pulverization.

Materials with fine particle size have poor fluidity. If liquid materials or high-moisture materials are added during the mixing process, the fluidity will be worse. Materials with poor fluidity require a longer mixing time to be evenly mixed.

Using an ordinary ribbon mixer, the livestock and poultry feed can be mixed evenly in three to four minutes, but it takes four to five minutes to mix for the production of aquatic feed.

However, once the materials with poor fluidity are evenly mixed, the automatic grading during the transportation, storage and other processing processes will be relatively slow, and the uniformity of the materials will be relatively stable.

When making hard pellets for fish feed, the compact structure of the fish pellets is conducive to the improvement of the water resistance of the pellets. One of the effective ways to improve the compactness of fish food pellets products is to increase the aspect ratio of the fish feed pellet machine die hole.

In the production of ordinary poultry and livestock feed, the animal feed pellet machine's die hole length-to-diameter ratio is usually 6:1-10:1, but when producing fish and shrimp feed, the length-to-diameter ratio of 10:1-12:1 is often used, such as using some special raw materials. Or to make feed for young fish and shrimp, the length to diameter ratio of the fish pellet making machine die hole needs to be as large as 12:1-16:1.

Under different finished product requirements and raw material conditions, different types of fish feed pellet making machines should also be considered. The diameter of the fish food pellets obtained by the ordinary fish pellet machine or fish feed extruder is often greater than or equal to 1.5mm.

In the production of feed for juvenile fish and prawns, pellets of φ2.0mm are usually produced first, and then crushed into small pellets with a pellet crumbler. This kind of small pellet is irregular, and more fragments are produced during the crumbling process.

In order to improve productivity and product uniformity, the fish food pellets grading sieve used in the production of aquatic fish food pellets often requires multiple sieve surfaces, so that the crumbled fish food pellets are classified into several levels according to the fish food pellets size to obtain feed suitable for fish and shrimp of different body lengths.

There are two types of post-cooker with steam and without steam. The non-steam post-cooker makes the material just out of the fish feed pellet machine a heat preservation and moisturizing process.

During this period, the internal stress of the fish food pellets generated in the fish feed pellet making machine pressing process is eliminated, the capillary channel is blocked, and the fish food pellets are further subjected to hydrothermal treatment to improve the water resistance of the fish food pellets.

To prepare ordinary fish feed, a post-cooker without steam can already be effective, but to produce shrimp feed, post-cooking needs to be strengthened, and it is necessary to use a post-cooker with steam.

After the material is post-cured, the water resistance will be significantly increased, but the surface of the smooth fish food pellets obtained by the friction of the fish pellet making machine pressure die hole wall will be corroded by water vapor, and the surface of the fish food pellets product will lose luster and appear rough.

The grease and heat-sensitive components of aquatic feeds are usually sprayed on the surface of the fish food pellets after the fish food pellets are cooled by spraying equipment, which can protect the active components. At present, the most advanced technology is the vacuum coating technology.

Its characteristic is to ensure the accuracy and uniformity of liquid spraying, which can greatly increase the amount of liquid added, and the trace components can penetrate into the fish food pellets, thereby reducing the loss of trace components and the pollution of grease to the water surface during use.

The pelletized hot fish food pellets are post-aged and enter the cooler for cooling. Since aquatic pellets have higher requirements for water resistance, the cooling rate should not be too fast to avoid cracks on the fish pellet surface. The most common fish food pellets cooling equipment used by feed manufacturers is the counterflow cooler, which has a good cooling effect.

The screening section mainly uses a grading screen to screen the fish food pellets of the required particle size, and the selection of the screen can be determined according to the needs. The rubber ball in the screen is best to choose a product with good elasticity and wear resistance to improve its screening capacity and service life.

Before packaging, check the color, impurity content, fish food pellets length, length uniformity, cut, static powder rate, powder content, water resistance, moisture, floatability, pelletizing coefficient, bulk density, softening time and other indicators before packaging the finished fish food pellets product. During the fish feed plant ackaging process, it is necessary to check regularly or irregularly according to the product standard.

Every fish feed manufactuer customer's needs are different. In short, the selection of aquatic feed processing technology and fish feed mill machine can be flexibly selected according to the requirements of breeding species, feed type, fish feed processing quality, combined with fish feed plant processing cost, site, and fish feed mill investment scale.

Is there still room for expansion in the agricultural production industry chain, which is tightly interlocked? The answer is of course yes, this is an area that many people have not noticed-aquatic feed.

At present, in the production of aquatic products, the proportion of aquaculture is increasing, especially the growth rate of freshwater aquaculture is the fastest. Now farmed small yellow croaker, pomfret, flounder, bass, etc. can be seen everywhere.

Affected by the lack of marine resources, the proportion of sea catching aquatic products is getting lower and lower, and the increase in the proportion of aquaculture will promote the growth of demand for aquatic feed.

The healthy development of the aquaculture industry is inevitable, and the safety of farmed fish is a must, and the transformation of aquaculture methods has released a huge demand for compound feed.

With the transformation of traditional aquaculture methods to resource-saving, environment-friendly, and quality-oriented modern aquaculture methods, safe, efficient, and environment-friendly aquatic compound feeds have broad market development space and will surely become the leading products in the future market.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.