With our organic fertilizer production project solution, fertilizer manufacturers will be able to successfully cope with the agricultural challenges of the future. Contact us to discover how we can help you capitalize on the growing demand for organic fertilizer processing.

100+

Construction Projects

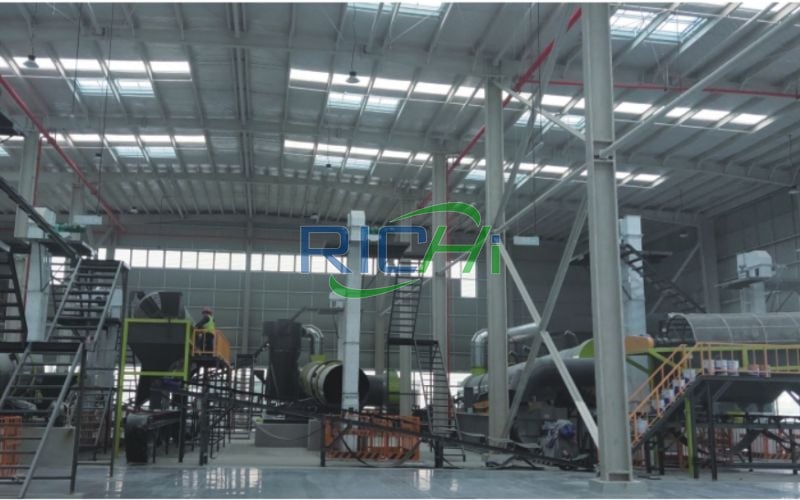

With over 30 years of continuous innovation, RICHI has achieved a total sales milestone of over 100 organic fertilizer plant projects, and it has become one of the major feed equipment manufacturers in the world.

$50 million

Total Sales

From conception to whole fertilizer production project delivery, our RICHI employees team work hand in hand to ensure the successful realization of your organic fertilizer projects.

70+

Covering Countries

RICHI Machinery is a full-service organic fertilizer equipment company that provides its global clients with a turn-key organic fertilizer manufacturing plant project solution for any challenge.

As a leading organic fertilizer production plant design and construction company, we know how to tailor our services to each individual client. Our team will learn everything there is to know about your current operations and your business goals. No one understands the needs of your business better than you. We take the time to get to know the ins and outs of your vision for a new facility while making suggestions along the way. And ultimately deliver the perfect organic fertilizer production project for you.

Country: Argentina

This is a sludge cow dung organic fertilizer production line in Argentina project. What is very special is that this project uses sludge and cow dung as the main raw materials.

Country: Japan

The client of this organic manure production plant In Japan project is a comprehensive agricultural company with two breeding farms and one fruit and vegetable base. In order to make full use of livestock and poultry breeding waste and agricultural and forestry waste, it invested in the construction of this 10,000-ton organic fertilizer project with an annual output.

Country: Senegal

The manure fertilizer pellet plant In Senegal project was invested and constructed by a Senegalese agricultural technology company, which was established on March 16, 2022. The customer built an organic fertilizer production project in the farm he operated, using livestock and poultry farming manure and sewage to produce 20,000 tons of organic fertilizer per year.

Country: Kyrgyzstan

This is a 6-ton fertilizer manufacturing plant in Kyrgyzstan, invested and constructed by a large breeding company in Kyrgyzstan. The client company of this project mainly operates large-scale breeding business, including multiple chicken farms. The chicken manure produced in these breeding farms is transported and harmlessly treated by a local company every day.

Country: Brazil

This is a bio organic fertilizer production line in Brazil project. The project mainly uses pig manure and straw as raw materials, and mainly processes powdered organic fertilizer.

Country: Ecuador

This is an organic fertilizer production plant in Ecuador project built using agricultural waste, with an annual production scale of 100,000 tons of bio-organic fertilizer. The project covers an area of 17,333.4m2 and a construction area of 6,740m2. Using existing land and houses, the project construction period only involves the construction of fermentation tanks and equipment installation and commissioning.

Country: Vietnam

This organic fertilizer factory in Vietnam project is engaged in the production of organic fertilizer, mainly processing powdered organic fertilizer and organic fertilizer granules. The client of this project is an ecological agriculture company, which invested 430,000 US dollars to build an organic fertilizer processing plant and organic fertilizer pretreatment center with an output of 8 tons per hour.

Country: Netherlands

The client of this organic fertilizer manufacturing plant in Netherlands project is an ecological agriculture company from the Netherlands, which invested 350,000 US dollars to build a 4t/h organic fertilizer production line project.

Country: Algeria

The biofertilizer manufacturing plant in Algeria project covers an area of about 5000m2, with a new steel frame closed production plant (building area 2812m2, height 8m) and a steel frame office area (two-story steel frame structure, building area of about 400m2). The main construction areas in the plant are raw material storage area, fermentation area, aging and composting area, crushing and screening area and packaging area.

Country: Austria

This is a compound fertilizer production line in Austria project with an output of 2 tons per hour. The customer processes a relatively special compound fertilizer: water-soluble fertilizer.

Country: Britain

This is a small capacity organic fertilizer processing project, which is located in the UK. The project mainly uses livestock and poultry manure as the main raw material, using fermentation and turning processes, without configuring ingredient mixing, granulation and other processes.

Country: Iraq

This is an expansion project of an organic fertilizer processing plant In Iraq. The customer originally had an annual production line of 8,000 tons of blended fertilizer. In November 2023, a new organic fertilizer production line project with an annual output of 50,000 tons will be invested.

When we begin a new design-build construction organic fertilizer production project, our team will plan out and analyze every aspect of the proposed design to make sure it will elevate your current business model and address specific concerns in the production process.

Country: Russia

Country: Thailand

Country: Mexico

Country: South Africa

Country: Poland

Country: UK

Country: USA

Country: Thailand

Country: Lithuania

Country: India

Country: Vietnam

Country: Pakistan

Country: Netherlands

Country: Brazil

Country: Indonesia

Country: Saudi Arabia

Country: Canada

Country: Norway

Our team at RICHI Machinery manages every aspect of the organic fertilizer production project build process, including the design, planning, engineering, and construction of your new organic fertilizer system.

With expertise across the agricultural, industrial and manufacturing industries, we can create a custom solution for your organic fertilizer production project.

The organic fertilizer production systems are made with the latest technological trends and industry standards in mind, ensuring optimal efficiency at every turn.

Meet global product demands and quality standards with industry-leading pellet plant design, engineering, equipment, and construction services for pellet processors.

Your Partner Beyond Project Completion

2000+ cases

RICHI is the leading designer, manufacturer and builder of pellet plants in the world, completing over 2000 projects in 140 countries across 6 continents.

Read More

Our line of processing equipment from pelleting, extruding, crushing, mixing, drying, cooling, screening, cleaning, grading, cooling, spraying, conveying and storage, combined with an in-depth understanding of your pellet production business, delivers maximized growth and value.

For nearly 30 years, RICHI Machinery has had the opportunity to work with a variety of industries – learning the complexities of diverse materials, navigating unique industry challenges, and discovering innovative pellet plant solutions along the way. Whether you work with feed, biomass, wood, organic fertilizer or cat litter products, RICHI is committed to being your partner in innovation, success, and operational excellence.

ANIMAL FEED

BIOMASS

WOOD

ORGANIC FERTILIZER

AQUA FEED

CAT LITTER

MUNICIPAL WASTE RECYCLING

SPECIAL PELLET PRODUCTION

Founded in 1995, RICHI Machinery began as a pellet machine manufacturer and pellet plant system provider that steadily grew into the comprehensive service and equipment provider it is today. We pride ourselves on the knowledge and skill that each team member possesses – from our technical sales team to our process design engineers. You can count on RICHI to take your operation to the next level of success.

Learn MoreWith our expert team, we precisely implement your process engineering requirements in pellet mill and pelletizing plant systems. No matter which industry you’re in – we understand your needs and deliver solutions that meet the highest standards.

At RICHI, quality comes first. Our pellet making machine and related pellet line equipment undergo rigorous quality controls to ensure they meet the highest standards. Rely on products that are durable, safe, and efficient.

With decades of experience in pellet machine and pellet production line production, we have earned a reputation as a trusted partner in various industries. Our expertise allows us to cover a wide range of applications.

Not only do we offer premium pelleting equipment, but we are also experts at designing, building, installing, and maintaining facilities from the ground up. Our expertise is within pellt plant process design, discovering the most efficient, productive, and profitable way to handle your materials in an end-to-end cycle.

We're here to answer any questions you may have and help you realize the future.

Organic fertilizer production plant cost is usually between 50,000-2,000,000 USD. Depending on the type of organic fertilizer, production scale, production process and equipment configuration, the fertilizer plant project cost is different. If you want to build an organic fertilizer production project, feel free to contact us, tell us your needs, and get a detailed equipment quotation!

We work with all types of organic fertilizer industries to provide turnkeysolutions for your particular needs. Our team will handle complex designs with the same care and level of detail as if it were our own. We design, engineer, integrate, supply, install, test & commission and manage all activities for turnkey execution of our systems projects.

Maintenance must occur or the rate of wear in a system will increase exponentially to the point of failure - Performing routine maintenance to your systems assures seamless operation. Repairing and servicing tools and machines for affordable prices, in our shop or at your location. Our trained mechanics work on a wider variety of tools and machines: from fertilizer pellet machines and generators to fertilizer dryer machine and turner.

Yes. Our team provides new product development and process equipment manufacture for the organic industry. From organic fertilizer granulator, to full set of organic fertilizer processing systems, we will work with you from concept to market on your fertilizer-related needs.

Our professional engineers will complete your organic fertilizer production project design and provide certification in accordance with the relevant: Australian, API or ASME standards. We have the ability to meet your two-dimensional and three-dimensional drafting requirements delivering: general arrangement and shop detail drawings.

If you need further information, please contact us

If I seem biased, it may be because of the results they have provided…their advice is sound. Their procedures are modern and proven. Their entire organization follows an organic fertilizer production project long after completion.

Gustavo Gutierrez

Project Manager——From Mexico

RICHI delivers most innovative and experienced resources to address every facet of the organic fertilizer production project. No other company provides its clients with the finest overall project experience and long-term value creation, project experience and long-term value creation, which is why RICHI’s clients are clients for life.

Keeping in touch with us is an effective way to solve all your problems. If you have any needs or questions, please leave your contact information, then RICHI technical consultants will send design, quotation, videos to your mailbox. You can also contact us directly via WhatsApp: +86 13838389622

Copyright©2015-2024 by HENAN RICHI MACHINERY CO., LTD. All rights reserved.