Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

The alfalfa pellet production line is a pellet feed made by processing alfalfa using a ring die pelleting process. It is rich in nutrients such as protein, minerals and vitamins, has high nutritional value, and is widely used in animal husbandry. Alfalfa pellets are products obtained by drying alfalfa and pelleting it. This form is conducive to storage and transportation. It is usually fed to ruminants such as cattle and sheep, and is mainly consumed by dairy cows. Alfalfa pellets have high protein content and can reduce the amount of concentrated feed to a certain extent. The alfalfa pellet line can be flexibly customized in modular form. Your raw materials can be grass meal, dehydrated alfalfa, or baled alfalfa.

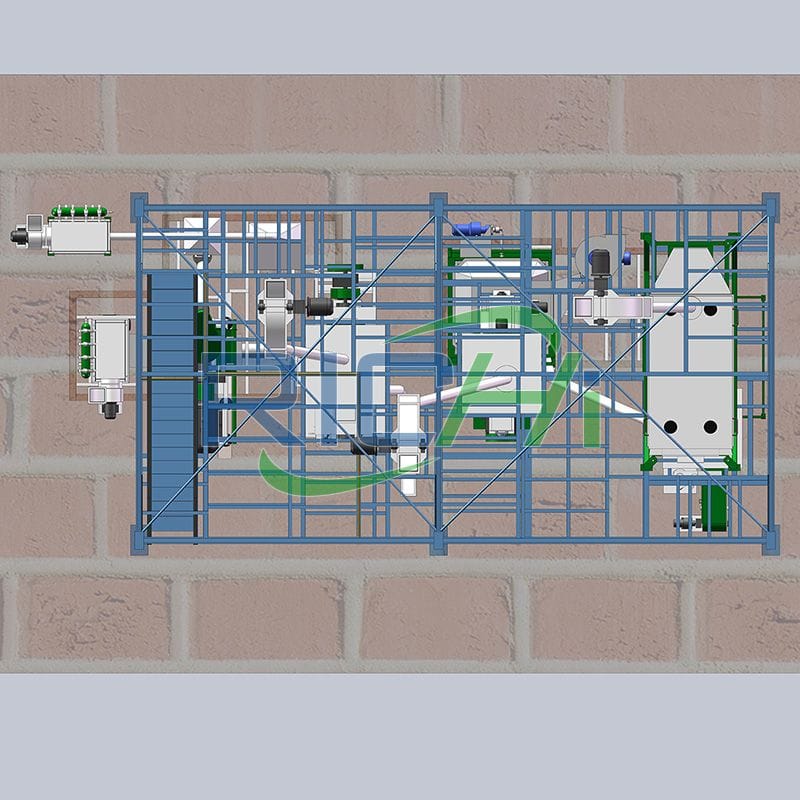

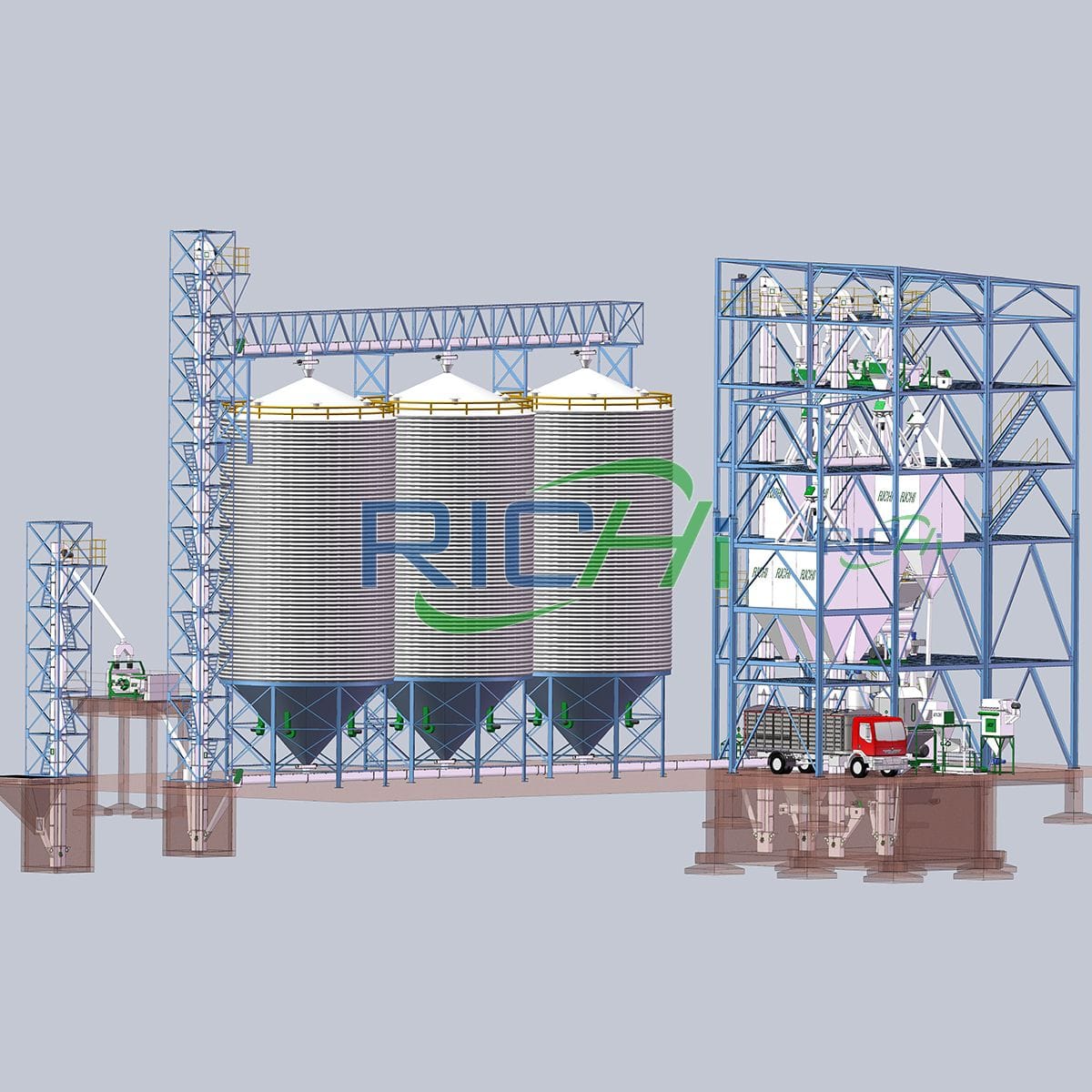

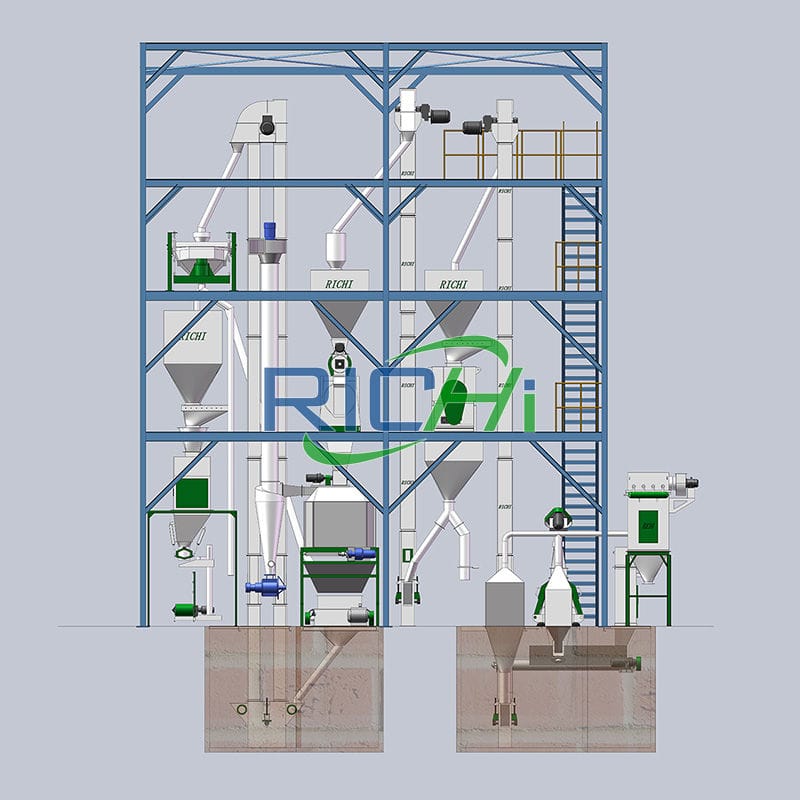

The following is the standard alfalfa pellet production line process flow. If the process you need is different from the following content, it doesn’t matter. Contact us to customize your alfalfa pellet plant and get a full set of production line equipment quotation.

The following is the standard alfalfa pellet production line process flow. If the process you need is different from the following content, it doesn’t matter. Contact us to customize your alfalfa pellet plant and get a full set of production line equipment quotation.

In short, the alfalfa pellet processing process includes raw material selection, pretreatment, crushing, mixing, granulation and packaging. Reasonable processing technology can produce alfalfa pellets with stable quality, good taste and rich nutrition to meet the nutritional needs of different animals.

Alfalfa pellets processed by alfalfa biomass pellet production line are short fibers, while alfalfa hay is long fibers. Adding alfalfa pellets to the diet formula of dairy cows can increase the dry matter intake of dairy cows, but the content of effective fiber in the dairy cow diet needs to be considered.

If you are interested in our hay pellet machine project and want to start hay pellet processing, contact RICHI Machinery for equipment details and a quote.

01

Product specifications

02

Production efficiency

03

Energy consumption and maintenance

04

Safety

05

Cost

In summary, there are multiple factors to consider when purchasing alfalfa pellet production line equipment. Sometimes price is not the only determining factor, but you should choose the alfalfa pellet processing equipment that suits you according to your own production needs.

The price of 0.6-90T/H alfalfa pellet production line is generally between 45,000-2,500,000 USD.

The alfalfa pellet production line cost varies depending on factors such as manufacturer, scale and configuration, so it is difficult to give an exact price. Here are some key factors that affect the price of alfalfa pellet plants:

Therefore, if you are interested in purchasing an alfalfa pellet production line, it is recommended to contact multiple suppliers to understand their quotes and sales conditions. RICHI Machinery, as an alfalfa pellet line manufacturer, can conduct a comprehensive evaluation and comparison based on actual needs, budget and quality requirements.

Alfalfa pellets processed by alfalfa pellet production line are a nutritious and widely used feed raw material. With the development of animal husbandry and the increasing demand for high-quality feed, the alfalfa pellet market has received a lot of attention in recent years.

Here we will analyze the prospects of the alfalfa pellet market, including market size, development trends and opportunities.

The alfalfa pellet market has continued to grow in the past few years, and the market size has gradually expanded. According to statistics, the global alfalfa pellet market size reached 8 million tons in 2022 and is expected to grow to 15 million tons by 2025. This growth trend is mainly driven by the development of animal husbandry and market demand.

Globally, Europe, North America and Asia-Pacific are the main consumption areas of the alfalfa pellet market. The European market accounts for 40% of the global market share, mainly driven by the demand of the breeding industry.

The North American market has also shown a rapid growth trend in recent years, mainly due to the increased demand for high-quality feed. The Asia-Pacific region is a potential market for alfalfa pellets.

With the development of the breeding industry and the improvement of agricultural technology, the market size will further expand.

The alfalfa pellet market has broad prospects and potential. With the development of the breeding industry and the increase in demand for high-quality feed, the market size will continue to expand.

At the same time, the improvement of nutritional value, the promotion of sustainable development concepts and the improvement of manufacturing technology will provide more opportunities for market development.

However, the market also faces technical challenges and brand building challenges, and needs to continuously improve its competitiveness in the competition. In summary, the alfalfa pellet processing business has broad prospects and is expected to achieve good development in the future.

Grass alfalfa pellets are hard, crushed grass, usually cylindrical with a diameter of 5-19 mm and a length of 13-25 mm respectively. The density of each unit grass pellet is about 1120 kg/m3.

In order to produce high-quality alfalfa pellets, drying is required. Before being placed in the dryer, the grass segments are kept in a cushion layer. A type of end-to-end unloader is used to place the grass segments into the alfalfa dryer.

The typical grass pellet production process is to obtain dehydrated alfalfa pellets by placing the grass segment product in a rotary drum dryer at 200℃-900℃ for about 3 minutes. The temperature of the dryer is determined by the degree of pre-wilting of the grass segments.

The moisture content of the grass segments delivered to the dryer can vary from 45% to 75%, or even higher. Rain can increase the moisture content of the feed. The final moisture content of the grass segments varies from 7% to 9%.

To produce naturally dried alfalfa pellets, the harvested alfalfa is harvested in a similar manner to that used for hay. Before baling, the stalks are raked once or twice to dry them evenly. In some areas, the stalks are picked up and formed into large round bales.

The bales are transported to the processing plant until there is no more fresh alfalfa for the season. The bales are crushed into segments 25 to 50 mm long. A hay crusher is the most commonly used device for reducing the size of hay.

The segments with a moisture content of 15% to 20% are placed in a rotary drum dryer for drying. The remaining operations are similar to those for producing dehydrated alfalfa pellets.

When choosing an alfalfa pellet production line manufacturer, alfalfa pellet processors should pay attention to the following key factors:

After comprehensively considering the above factors, customers can choose an alfalfa pellet plant equipment manufacturer that suits their needs. It is recommended that consumers conduct more market research and comparisons when purchasing alfalfa pellet production line equipment, and try to cooperate with reputable and powerful manufacturers to ensure the quality and service level of the selected products.

At the same time, it is also hoped that alfalfa pellet production line manufacturers can continuously improve product quality and service levels in the fierce market competition, and provide users with better products and services.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.