Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Hay pellet machine is a kind of feed pelletizing equipment used to process various types of hay pellets. It is a kind of grass feed pellet machine. It adopts the ring die pelletizing process and is equipped with a forced feeder. The raw materials suitable for this equipment include Grass Hay, Alfalfa Hay, Teff Hay, Orchard Hay, Timothy Hay, Bermuda Grass Hay, etc. Hay pellets are a type of animal feed that are made from dried and compressed hay. They are commonly used to provide nutrition to livestock such as horses, rabbits, and cattle, sheep among others.

Hay pellets serve as a substitute for hay and can enhance the basic feed. The hay pellets are made from grass that has been mown at the optimal time. The mown grass is dried by a warm air process, then crushed and pressed into hay pellets.

Hay pellets offer several advantages over traditional hay, including improved digestibility, reduced dust and waste, and ease of handling and storage. They are particularly popular in regions where hay availability is limited or during winter months when fresh forage is scarce.

Hay pellets do not contain irritant dust, which makes them particularly suitable for livestock with respiratory diseases. In addition, softened hay pellets are easier to chew and process for livestock with dental problems. Moreover, they have a high crude fiber content, which is necessary for the livestock's digestion.

Among many feeds, in addition to silage and hay, pellet feeds are widely used because of their good applicability. Pellet hay feed refers to pulverizing and mixing feed raw materials and concentrated feed, and pressing them into granular feed with different diameters through a special die.

In particular, feeding hay pellet feed can significantly improve the growth performance of livestock and poultry. The hay pellet mill machine is the core equipment to realize the pelletizing function. It has the following technical features:

| Type | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output(t/h) | 0.7-4 | 1~6 | 2~10 | 3~15 | 4~30 | 5~40 |

| Main motor power(kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 6/8P | |||||

| Forced Feeder (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 3 |

| Conditioner Power(kw) | 2.2 | 4 | 7.5 | 7.5 | 11 | 15 |

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel conditioner Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

|||||

Currently, our hay pellet maker machines have been exported to more than 100 countries around the world and are used in cattle, sheep, horses and rabbit feed mills and farms of various sizes.

If you are interested in our hay pellet machine project and want to start hay pellet processing, contact us for equipment details and a quote.

The most critical technology for processing grass pellets is to adjust the moisture content of the raw materials.

Hay pellets containing different nutritional components can be formulated according to the nutritional requirements of various livestock and poultry. The pellet size can be adjusted by the hay pellet machine and processed as required.

The purpose of hay pellet feed processing is to mix pure hay powder or hay powder with other concentrated feed raw materials into complete ration feed according to animal growth needs and animal nutrition formula requirements, and process it into pure hay pellets and complete ration hay pellet feed. The types of hay pellet feed currently commonly used are as follows:

01

100% Pure hay pellets production

02

70% hay pellet feed production

03

80% hay complete diet pellets production

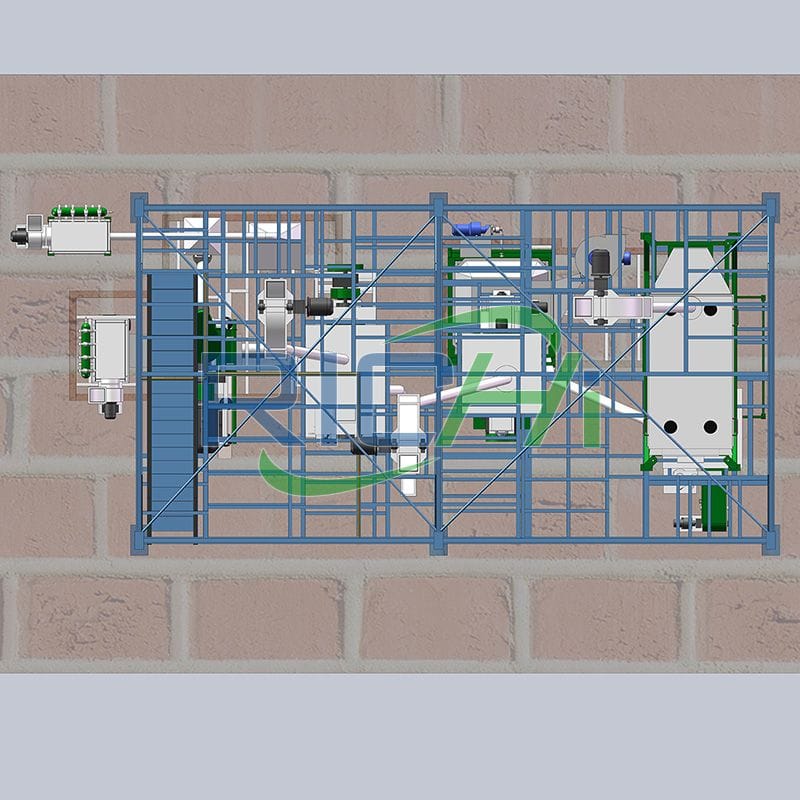

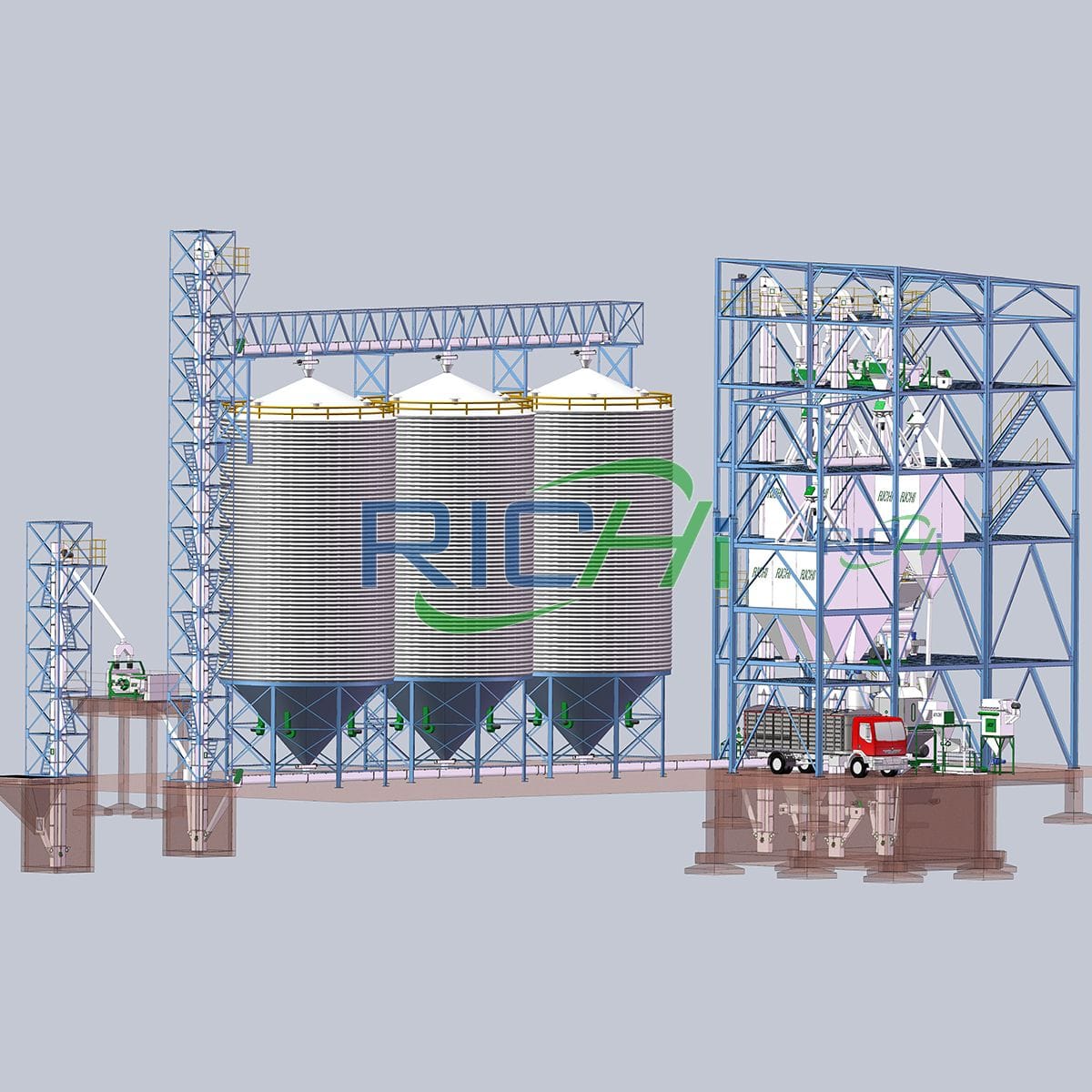

Each customer's raw material conditions (moisture content, size), formula, and process requirements are different. Therefore, we usually customize the hay pelletizer system and the entire hay pellet plant according to the customer's actual situation.

Whether your raw material is hay bales, grass meal or wet grass, RICHI Machinery can design the process according to your raw materials and formulas.

The price of hay cubes pellet machine is generally between 10,000-100,000 USD.

Factors that affect the price of ring die hay pellet machines include:

When choosing a hay pellet making machine manufacturer, you need to pay attention to the following aspects:

Hay pellet machines are high-precision and high-tech equipment, and technical strength is the primary consideration when choosing a manufacturer. You can understand the technical strength of a manufacturer by looking at its technical team composition, technical research and development capabilities, technical patents, etc.

At the same time, you can also ask for relevant technical information and cases from the manufacturer to have a more comprehensive understanding of its technical level and application experience.

The manufacture of hay pellet machines requires high-precision processing equipment and strict quality control processes. Therefore, it is very important to choose a manufacturer with advanced production equipment and a complete quality management system.

You can evaluate the manufacturer's production capacity and quality assurance level by visiting the manufacturer's production workshop, understanding the production process, and viewing product quality inspection reports.

The hay pellet machine is a kind of machine, and some problems will inevitably occur during use. Therefore, choosing a hay pelletizer manufacturer with a complete after-sales service system can provide users with better technical support and maintenance services.

You can learn about the after-sales service level of the manufacturer by consulting the manufacturer's after-sales service policy, understanding the after-sales service team, and viewing after-sales service cases.

Quotes from different manufacturers may vary greatly, so you need to choose the right manufacturer based on your needs and budget. It should be noted that price is not the only consideration and needs to be considered comprehensively in conjunction with the above aspects.

It is recommended that when choosing a hay pellet machine manufacturer, you can conduct more market research and on-site inspections to understand the advantages, disadvantages and characteristics of different manufacturers in order to make a more informed choice.

At the same time, attention should also be paid to establishing good communication and cooperation relationships with manufacturers to ensure that timely and effective technical support and services can be obtained during use.

In short, choosing a hay pellet mill manufacturer requires comprehensive consideration of many aspects, including technical strength, production capacity, quality assurance, after-sales service and price level.

Through comprehensive evaluation and comparison, selecting manufacturers with advantages and potential can bring better user experience and economic benefits to users.

The market analysis of hay pellets reveals a steady growth rate, with the market expected to grow at a CAGR of 13% during the forecast period. One of the key drivers of this growth is the increasing demand for animal feed due to the rising global population and changing dietary preferences towards meat consumption.

Additionally, the growing awareness of the benefits of hay pellets, such as their high nutritional content and lower moisture content, is further driving market growth.

The hay pellets market is witnessing several trends that are shaping its growth trajectory. One significant trend is the increasing adoption of hay pellets in the equestrian industry. Horse owners are recognizing the benefits of hay pellets in providing a consistent quality feed, reducing waste, and improving overall horse health.

Furthermore, the rising popularity of small-scale farming and backyard livestock raising is driving the demand for hay pellets. These pellets are more convenient to store and transport compared to traditional baled hay.

Another emerging trend in the market is the growing demand for organic hay pellets. With the increasing awareness of sustainability and environmentally friendly practices, consumers are seeking organic and pesticide-free animal feed options. This trend is expected to drive the market for organic hay pellets in the coming years.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.