Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

The straw pellet making machine is a biomass pelletizing machine that uses corn straw, cotton straw, flax straw, soybean straw, rice straw, wheat straw and other agricultural waste as raw materials. It has the advantages of high efficiency, environmental protection, and energy saving. It is solidified and formed into high-density pellet fuel and pellet feed through pretreatment and processing, which can not only save energy but also reduce emissions, economic benefits and social benefits. This straw pellet machine is widely used in the field of agricultural production, greatly It facilitates people's work and saves time.

RICHI straw pellet making machine can be applied to a wide range of raw materials, has good pellet forming effect, and has strong support from the governments of many countries. It has the following technical advantages:

Our straw pellet making machine can be used for processing fuel pellets, feed pellets and fertilizer pellets. However, for different pellet products, the designs of the agri straw pellet machines we provide are different, but their working principles are basically the same.

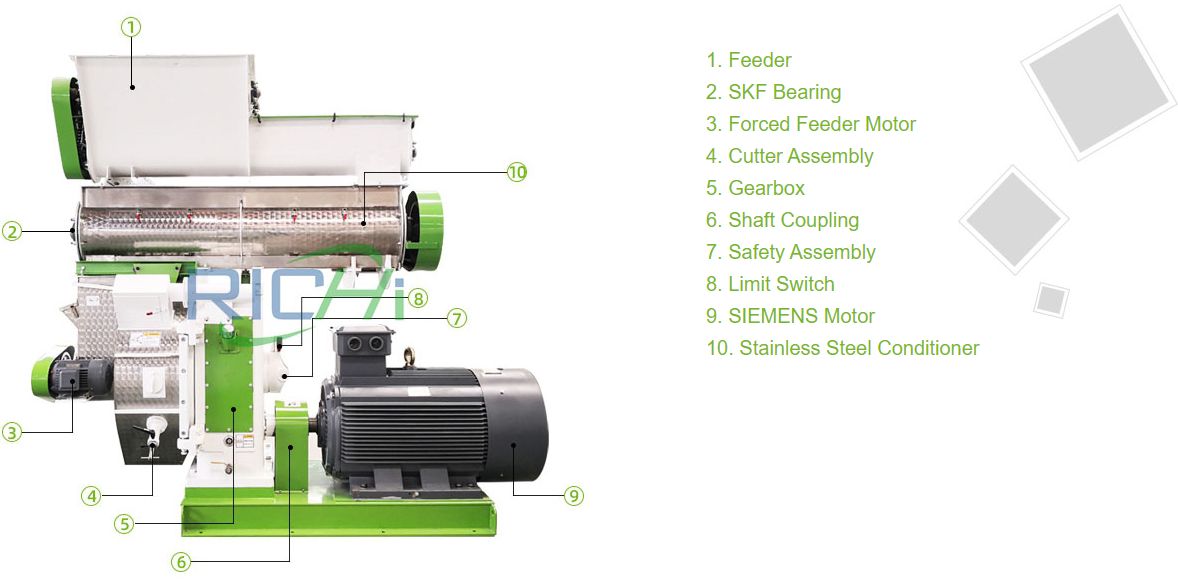

However, when processing feed, due to the differences in customer formulas, a conditioner needs to be configured to increase the content of the material. Ripeness for feeding to livestock.

With the gravity power, the centrifugal force generated by the rotation of the ring die, and the feeding scraper, the steam conditioned powder materials will be evenly fed into the two pressing areas in the ring die, which is a wedge-shaped space formed by the ring die and the two rollers.

Under the strong pressure between the ring die and the pressing rollers, the materials are gradually compacted, squeezed into the die hole of the ring die and formed to pellets in the die hole.

Because the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in the shape of a column, and then cut by the cutter into straw pellets with the required length.

| Type | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output(t/h) | 0.7-4 | 1~6 | 2~10 | 3~15 | 4~30 | 5~40 |

| Main motor power(kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 6/8P | |||||

| Forced Feeder (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 3 |

| Conditioner Power(kw) | 2.2 | 4 | 7.5 | 7.5 | 11 | 15 |

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel conditioner Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

|||||

At present, our ce straw pellet machines have been exported to India, Germany, Australia, Canada, Malaysia, Thailand, South Africa, Senegal, Ghana, Brazil, Argentina, Saudi Arabia and other countries. The equipment we currently export is mainly used for processing livestock straw feed pellets and straw fuel pellets.

The straw pellet machine price is generally 7,000-100,000 USD. Our equipment can be customized according to customer material status and process requirements.

There are many factors that affect the price of straw pelletizer machine. Here are some common factors:

These factors interact and comprehensively affect the price of straw fuel granulator. The importance of the above factors may vary depending on the type of machinery and market environment.

When choosing a field straw pelletizer, you need to consider many factors to ensure that you purchase a suitable and high-quality machine. The following will introduce in detail how to choose a straw pellet machine from the following aspects.

01

Understand the purpose

Before choosing a straw pellets machine, you need to clearly understand the purpose of the machine. Is it used for home heating or industrial production? Different uses have different requirements for the machine's output, quality, efficiency, etc.

If it is used for home heating, you can choose a small, portable machine; if it is used in industrial production, you need to choose a machine with larger output and higher efficiency.

02

Consider output

According to the purpose, choose a straw pellet mill machine with appropriate output. If the output is too small and cannot meet production needs, it will affect work efficiency; if the output is too large, it will increase production costs and cause waste.

Therefore, it is necessary to select a machine with appropriate output based on actual needs.03

Pay attention to quality

Quality is one of the important factors to consider when choosing a straw pellet making machine. The pellets produced by high-quality machines have high quality, high density, high calorific value, good combustion effect, and can improve usage efficiency.

Therefore, when choosing straw pelletizer machine, you need to pay attention to the quality and workmanship of the machine.

04

Focus on efficiency

Efficiency is one of the important factors to consider when choosing a straw pellet machine. Efficient machines can quickly process straw into particles, improving production efficiency and reducing production costs.

Therefore, when choosing a machine, you need to pay attention to efficiency and choose an efficient and fast machine.

05

Compare straw pellet machine prices

Price is one of the important factors to consider when choosing a straw pellet making machine. Different brands and models of machines have different prices, as well as differences in performance, quality, etc.

Therefore, when choosing a machine, you need to compare the prices of different products and choose the product with the highest price/performance ratio within your budget.

06

Examine the ease of operation

Ease of operation is one of the important factors to consider when choosing a straw pellet making machine. If the machine is easy to operate and easy to use, labor costs and time costs can be reduced.

Therefore, when choosing a machine, you need to examine the ease of operation and choose a machine that is easy to operate and maintain.

07

Ensure safety and reliability

Safety and reliability are one of the important factors to consider when choosing a ce straw pellet mill. The machine should be equipped with reliable safety protection devices that can automatically shut down or alarm under abnormal circumstances to ensure the safety of personnel and equipment.

Therefore, when choosing straw pellet machine, you need to pay attention to safety and reliability and choose products with safety protection devices.

08

Consider energy conservation and environmental protection

Energy saving and environmental protection is a hot issue of current social concern, and it is also one of the important factors to consider when choosing a straw pelleting machine. High-quality machines should be energy-saving and environmentally friendly, able to reduce energy consumption and pollutant emissions, and contribute to the cause of green environmental protection.

Therefore, when choosing a machine, you need to pay attention to energy saving and environmental protection performance and choose products that meet environmental protection standards.

To sum up, there are many factors to consider when choosing a super quality biomass straw pellet machine, including usage, output, quality, efficiency, price, ease of operation, safety, reliability, energy saving and environmental protection performance, etc.

Only on the basis of a comprehensive understanding of these factors can we choose a suitable and high-quality straw pellet making machine.

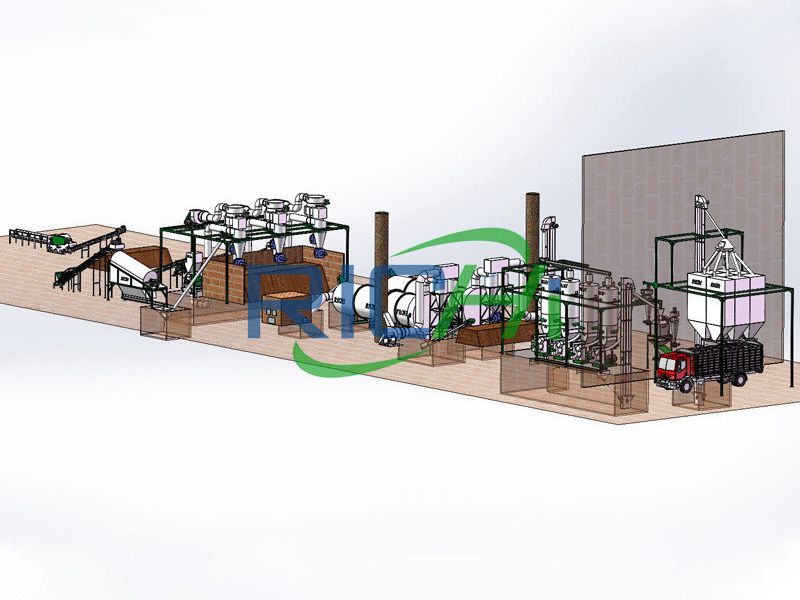

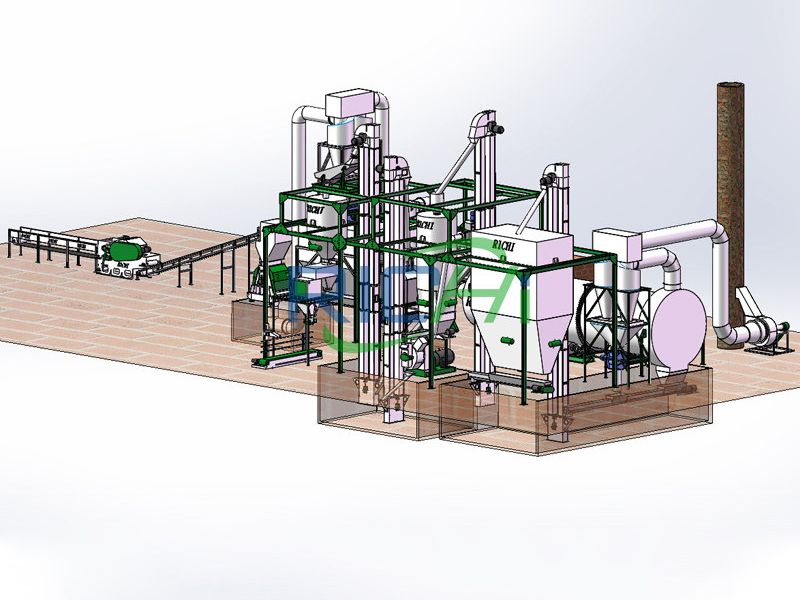

The processing flow of straw pellets:

The above is the conventional straw pellet production line processing process. We can customize different pellet production solutions for you based on different sites, raw materials, output, and budgets.

As the industry's leading straw pellet machine manufacturer, RICHI Machinery has rich experience and can build a complete straw pellet factory for you based on actual conditions.

A complete straw pellet manufacturing plant requires straw pellet making machine, straw pulverizer, straw dryer, straw pellet screening machine, straw pellet cooler, straw pellet packaging scale and other equipment.

According to the physical state of the straw raw material, production scale, and pellet usage, we will configure corresponding equipment for customers to provide you with the most valuable straw pellet production line.

In rural areas, discarded straw is often piled randomly or burned directly, causing serious pollution and waste. After using a straw pellet making machine to make straw into granules, it can be widely used in large biomass power plants, cooperatives, farms, straw processing and other fields:

Straw pellets processed by a straw pelletizing machine have the following advantages:

As an environmentally friendly and renewable new energy fuel, straw pellets have broad application prospects and economic value. People should strengthen the popularization and promotion of their knowledge, further promote the utilization and regeneration of straw resources, and jointly establish a sustainable ecological environment.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.