Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

Email Address enquiry@pellet-richi.com

Phone/Whatsapp 0086-13838389622

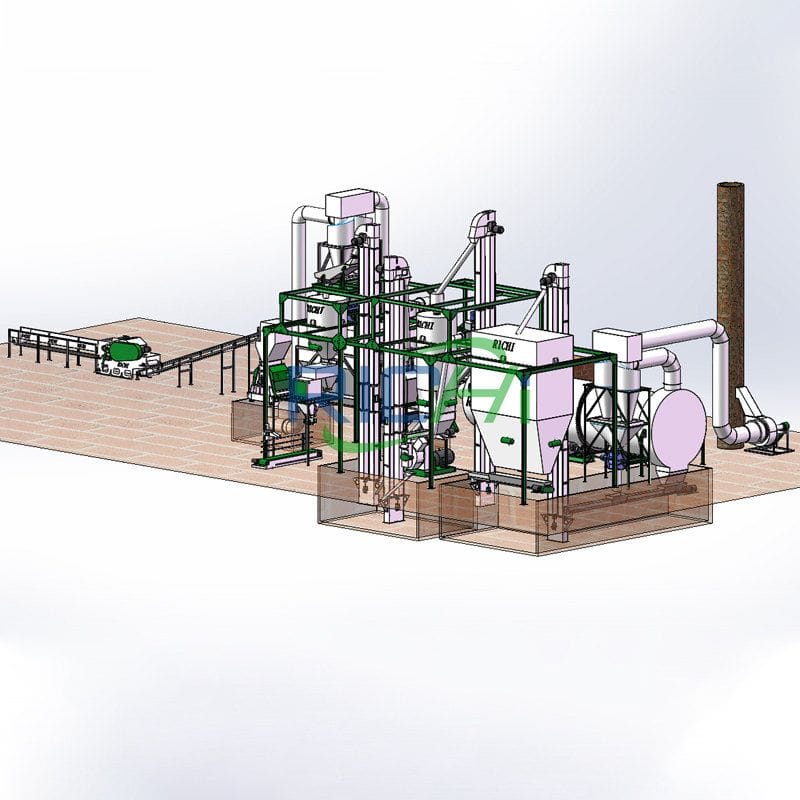

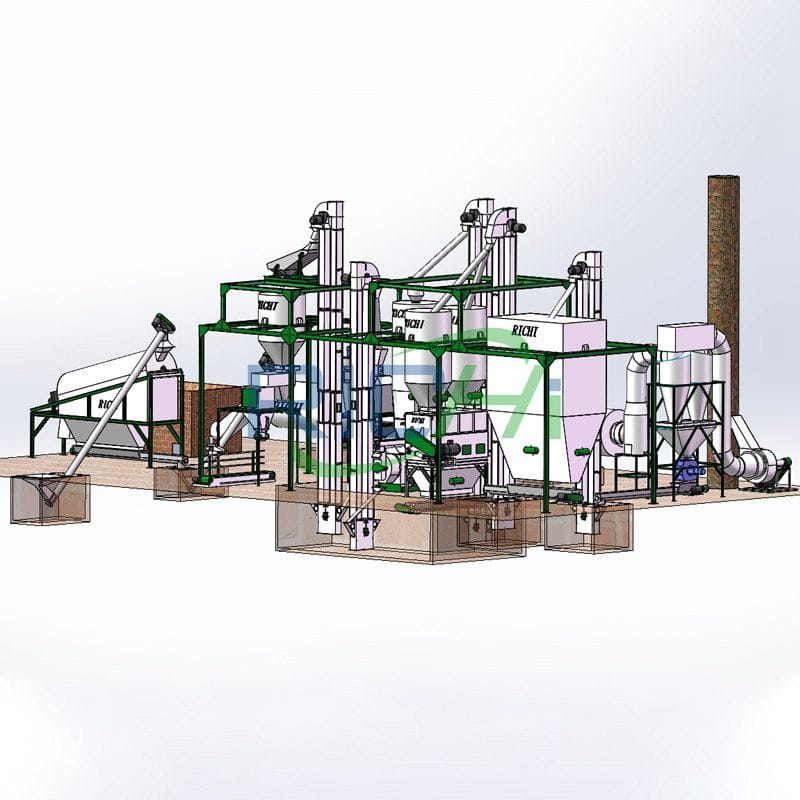

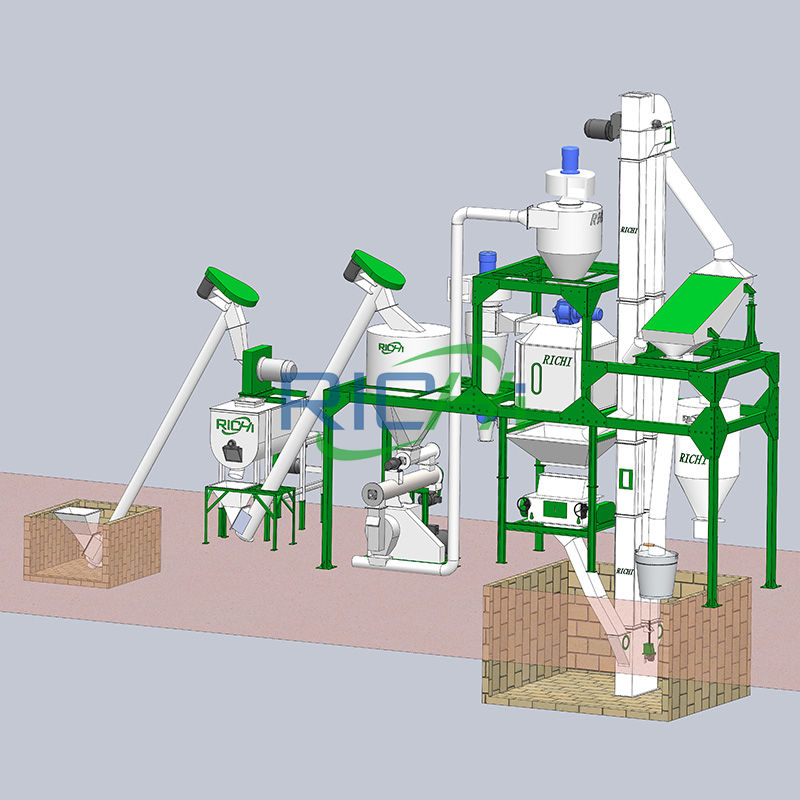

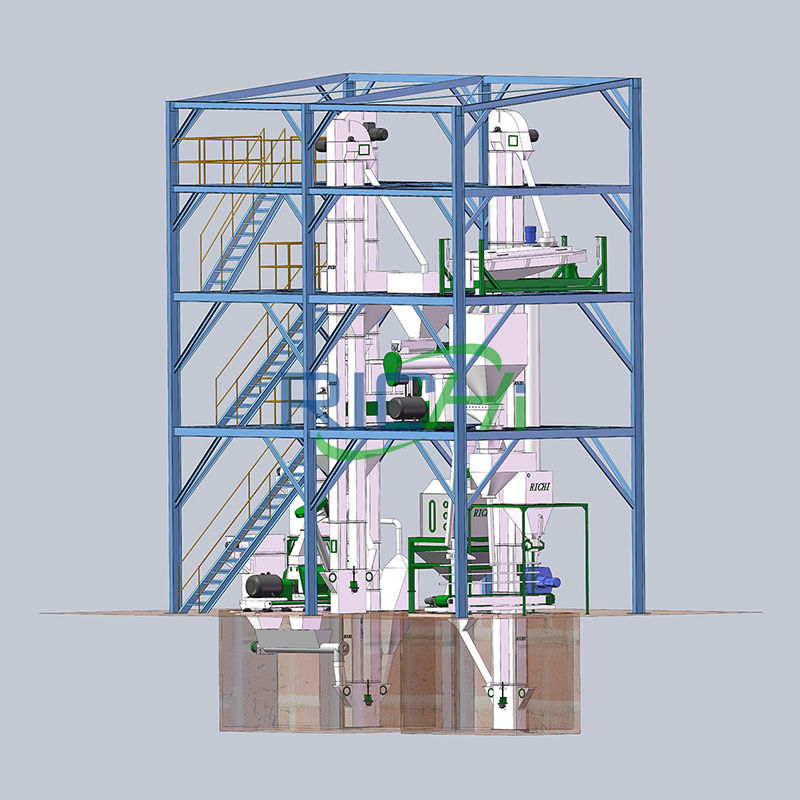

Straw pellet production line is a complete system that crushes, compresses and forms pellets of various crop straws, usually including cleaning, crushing, granulation, cooling, screening, packaging and other sections. Its basic principle is: through mechanical coercion, the raw materials are subjected to mechanical effects such as extrusion and friction, so that their own moisture content gradually decreases, becoming stable pellets without water or with extremely low moisture content. This production line is mainly used in the fields of feed, biomass fuel, etc., which can effectively utilize resources and reduce environmental pollution. In the future, straw pellet production line will have a wider application prospect and play an important role in the field of environmental protection and energy conservation.

Straw pellet line can directly process crop waste such as corn straw, rice straw, cotton straw, soybean straw, flax straw, etc., into pellets, which are mainly used in the fields of feed, biomass fuel, etc. When processing these different types of straw pellets, the process of straw pellet production line is different.

Straw pellets are widely used in daily life. Usually, straw pellets can be used as animal bedding, animal feed, and heating fuel for household and industrial use.

At present, our straw pellet production line equipment has been exported to many areas with rich straw resources, such as India, Uzbekistan, South Africa, the United States, Russia, Thailand, Brazil, Argentina, Australia and other countries.

If you are interested in our hay pellet machine project and want to start hay pellet processing, contact us for equipment details and a quote.

According to the different uses of straw pellets, straw pellet production lines are mainly divided into straw fuel pellet production lines and straw feed pellet production lines. The following is a detailed introduction to two different types of straw pellet processing technology:

Straw solidification molding technology uses agricultural waste such as rice straw, wheat straw, corn straw as raw materials, and uses special equipment straw pellet machine to crush, compress and other processes to press into a solid biomass fuel that can be directly burned.

The solidified biomass pellet fuel has a high specific gravity and small volume, which is convenient for storage and transportation. It is a high-quality solid fuel with a calorific value of 3200-4500 kcal. It is flammable, has low ash content and low cost. It can replace firewood, raw coal and other fuels and is widely used in heating, domestic stoves, industrial boilers, biomass power plants, etc.

As a new commodity energy, straw pellet fuel has been widely used in various industries. Moreover, due to its high density, high calorific value, regular shape and good fluidity, it is very convenient to realize automatic combustion control, which can save a lot of energy costs for enterprises.

Due to the similar composition of straw to wood, straw can be used to make grass pulp or converted into straw pellets. According to the particularity of straw, the granulation process of straw can be summarized as follows:

No matter what your raw material ratio is, no matter what your raw material material state is, no matter what the straw pellet size and compression ratio you want to process is, we can customize the corresponding straw pellet production line process according to your needs, and manufacture, install and debug all production line equipment.

Scientific and reasonable selection of straw pellet plant equipment is the key to ensuring production efficiency and product quality.

It is necessary to comprehensively consider factors such as production scale, product properties, production process, and conduct detailed supplier evaluation to select suitable production equipment and improve production efficiency and product quality.

The price of straw pellet production line is generally 40,000-2,500,000 USD.

In the booming development of the straw pellet processing industry, the straw pellet production line is a key manufacturing link, and its price fluctuations are comprehensively affected by many factors.

The following are the main factors that determine the price of a straw pellet production line and their in-depth interpretation, so that everyone can have a comprehensive understanding of the price and avoid spending too much money on purchasing a straw pellet production line.

01

Advancement of equipment technology:

02

Automation level:

03

Personalized customization:

04

Modular design flexibility:

05

Cost of basic materials and accessories:

06

Installation and debugging services:

07

After-sales maintenance and technical support:

The price of a straw pellet production line is affected by many factors, including technical complexity, degree of automation, customization needs, modular design, quality of raw materials and accessories, and after-sales service.

When selecting a straw pellet production line, straw pellet processors should make comprehensive considerations and trade-offs based on their actual needs, budget and long-term development strategy. Only by deeply understanding and mastering these price drivers can we find a cost-effective straw pellet production line solution in the market competition.

With the increasing awareness of environmental protection, the straw pellet production line project has attracted more and more attention. This project is to process crop waste such as straw into efficient and environmentally friendly fuel or feed.

This product can not only be widely used in the local market, but can also be exported to other countries, with broad market prospects. According to market analysis, the annual growth rate of this industry will exceed 30% in the next few years, and the overall market size is huge.

The straw pellet production line project is an investment project with broad prospects. For investors, it is recommended to pay attention to the following aspects:

In general, the straw pellet production line project has high market prospects and investment value. Investors can choose the investment direction that suits them according to their own circumstances.

Introduction of RICHI

Strength certification

Richi Machinery is a professional manufacturing enterprise integrating scientific research and development, manufacturing, sales and service. We have developed and manufactured multifunctional pelletizers, grinders, mixers, dryers and more than ten categories and more than 30 models of complete machine products are widely used in feed, biomass, organic fertilizer, pet supplies, solid waste recycling, chemical industry, road construction and other fields.

All RICHI products have passed ISO9001:2008 international quality system certification, EU CE certification and Customs Union CU-TR certification, successfully serving more than 2,000 customers in more than 100 countries and regions around the world.

In RICHI, every equipment and every pellet production line business plant can be customized. We will formulate multiple sets of pellet production process plans for comparative analysis according to the actual needs of customers, select a reasonable plan, and realize private customization.

Our services run through all aspects of on-site terrain and environment survey, production line process design, raw material testing, cost requirement analysis, project investment budget, equipment installation and commissioning.

Quality Control

Richi Machinery

We adhere to the ISO9001 quality management system, and strictly implement international standards for product design and manufacturing processes. In terms of management systems, there are product quality accountability systems, product quality accountability systems, and safety production management systems; in terms of management tools, QC quality control management, SPC statistical process control, sampling inspection and measurement system analysis are used for quality control, to achieve effective control of the entire process of equipment production, and never let go of any quality hidden dangers that may affect customer operations.

RICHI has always been adhering to the spirit of craftsmanship to make every detail good, especially in the link of equipment preparation and delivery, we follow the standardized process: preparation order check-equipment factory quality inspection-packing list re-inspection-scientific packaging and transportation, ensure the safe and non-destructive delivery of equipment.

According to customer needs, RICHI installation engineers will guide the construction of site infrastructure, equipment installation and commissioning and trial operation of the entire production line throughout the process. When the relevant project indicators reach the design standards, the client will carry out the project acceptance.

After-sales And Training

Richi Machinery

We have built a team of nearly 100 technical engineers to solve a series of problems in the project from consultation, site survey, sample analysis to plan design, installation and commissioning, and maintenance. We provide comprehensive and systematic training for the technical staff of each customer to better serve the customer's project needs.

After the technicians have finished their studies, RICHI will provide follow-up technical support services, and the training engineers will follow up the project use effects in the later stage to ensure the stable operation of the customer's project.